P 6 / 9

R

epair

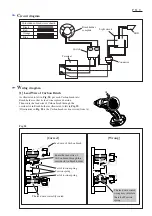

[3] -2. Disassembling/Assembling Bit Holder Section

1) Put A

nvil on Pipe 30 (No.1R232). (Fig. 13)

2) Put your thumb on the top of Sleeve so that Compression spring 13 does not pop out of Sleeve. (

Fig. 14)

3) While e

xpanding Ring spring 11 using Retaining ring S and R pliers (No.1R291). raise the opposite side of the Ring

spring with index finger. (

Fig. 14)

4)

Now the bit holder section can be disassembled as illustrated in Fig. 15.

Do the reverse of disassembling steps.

Fig. 13

Fig. 14

ASSEMBLING

DISASSEMBLING

[3] -3. Disassembling/Assembling Motor Section

1) Separate the assembly of Armature and Yoke

unit from the machine

.

(Refer to 1) to 4) of [3] -1. Disassembling

Hammering Mechanism.)

2) Put the assembly of Yoke unit and Armature

on a work bench so that the drive end of the

Armature touches the work bench.

Then separate Yoke unit from armature by

pressing it down towards the work bench.

(

Fig. 16)

.

DISASSEMBLING

No.1R232

Anvil

Hammer case

Sleeve

Ring spring 11

Sleeve

Important:

Do not forget to mount Nylon washer. (Fig. 15)

Put your thumb on

the top of Sleeve.

Raise this side

with index finger.

Expand Ring spring 11

using No.1R291.

Fig. 15

Hammer case

Nylon washer

Sleeve

Steel ball 3.5

Anvil

Compression spring 13

Flat washer 12

Yoke unit

Fig. 16