P 3 /15

R

epair

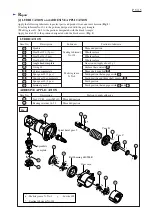

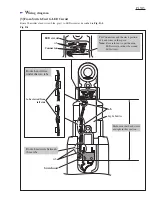

[2] LUBRICATION and ADHESIVE APPLICATION

Apply the following lubricants to protect parts and product from unusual abrasion (Fig. 1):

Sealing lubricant No.101 to the portions designated with the gray triangle

Makita grease N. No.2 to the portions designated with the black triangle

Apply Loctite 603 to the portions designated with the black arrow. (Fig. 1)

LUBRICATION

Fig. 1

Item No.

Description

Portion to lubricate

Spindle

Threaded portion

Angle head complete

Gear room (Apply about 2g.)

ADHESIVE APPLICATION

Item No.

Description

Portion to apply adhesive

Bearing retainer 14-23

Threaded portion

Torx C.S.H. screw M5x10

Threaded portion

Whole surface

Whole surface

Teeth portion and three shaft pins for

Teeth portion

Surface that contacts

Steel ball 5.0 (3 pcs)

Steel ball 4 (3 pcs)

Whole surface

Steel ball 3 (13 pcs)

O ring 14

Spur gear 13 (3 pcs)

Spur gear 20 complete A

Spur gear 18 (3 pcs)

Teeth portion that engages with and

Internal gear 47

28

Three shaft pins for

Carrier complete A

40

40

Teeth portion that engages with 41

42

1

36

36

35

13

14

17

19

21

42

43

37

41

40

13

14

17

19

21

42

43

35

41

40

42

Cam D

Gear case

Ball bearing 6805LLB

Spiral bevel gear 9

37

Cam C

Spindle A

complete

1

: Makita grease N. No.2

: Loctite 603

: Sealing lubricant No.101

Lubricant

Makita grease

N. No.2

Sealing lubricant

No.101