39

5.1.3. Service your loader at the intervals and locations as specified. When you service your loader, use only high

quality lubricants. The engine hour meter on the tractor shows the amount of hours the engine has worked. Use

the hour meter to service your loader at the correct time periods.

IMPORTANT: Lower the loader boom to the ground and relieve pressure in loader hydraulic lines prior to

doing any service or maintenance operations on the tractor or loader. Check the tractor hydraulic fluid

level as specified in the tractor operator manual.

NOTE: When checking hydraulic system fluid level, the loader boom must be on the ground with the

bucket or attachment resting flat on a level surface.

5.2. LOADER LUBRICATION AND SERVICE

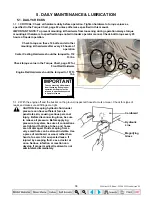

5.2.1. There are 12 grease fittings on this loader, one at each pivot. Lubricate pivots as specified. Use a grease

gun with a flexible hose.

5.2.2. Lower loader boom until bucket or attachment

rests on ground, and relieve all hydraulic pressure

before lubricating.

(1) Lubricate these 12 pivot points

every 5 hours of operation.

5.2.3. During initial setup, and as required; apply a

small amount of grease to each tower in areas of

tower bottom reciever (A), tower top receiver (B), and

inside handle pin hole (C). This will aid in parking

loader.

Tower

1

1

1 1

1

1

A

C

B

35 Series 4WD, Model - 3535 & 4035 Loader June’08