18

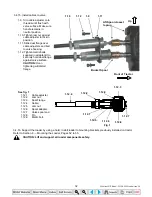

3.2. MOUNTING KIT INSTALLATION

3.2.1. Position the tractor and loader on a hard level surface under a hoist.

3.2.2. Remove front weights from tractor if applicable.

IMPORTANT: Do not tighten any hardware until all components are attached onto the tractor.

CAUTION: Lift and support all loader components safely.

1.

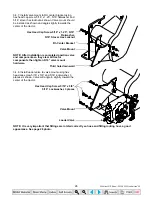

CRITICAL INFORMATION:

To install the Disc-Lock

Washer, simply mate the cams together and place

between the bolt head and the bracket. As the bolt is

tightened, one center of the Disc-Lock Washer is seated

to bracket material and the other to the head of the bolt.

When the bolt elongates due to vibration and shock, the

bolt will attempt to rotate loose. As one center of the

Disc-Lock Washer tries to rotate with the bolt, the

interlocking cams work against each other. This will

increase the preload, further locking the assembly and

reducing the chance of bolt loosening.

Bolt Threads

Bracket Material and/or

hardened flatwasher

Disc-Lock Washer

(angled grooves must

be matched together)

Bolt Head

Flat Grooves

Angular Grooves must

go toward bolt head

be matched together

Flat Grooves go

Angular Grooves

toward bracket material

must be matched

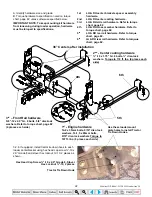

3.2.3. Remove the tractor toolbox, right

hand tractor step, tractor tie down hooks

and six tractor engine bolts as indicated.

Discard tractor hardware. Remove tractor

tie down hook if equipped.

Remove these engine bolts

Remove Tractor Toolbox, right hand

Step and Tractor Tie Down Hooks

IMPORTANT: DO NOT REMOVE

THESE BOLTS

IMPORTANT: Proper use of flatwasher, disc-lock washer and lockwasher will ensure that bolt will not

bottom out in tractor castings. Be sure to follow detailed instructions on following page for correct

washer and bolt usage.

35 Series 4WD, Model - 3535 & 4035 Loader June’08