-7-

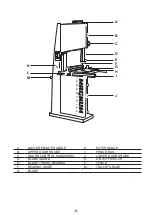

Quick release / blade tensioning

Lifting the quick release handle to release blade tension. Remove blade and replace with new

one. Turn down the handle to tighten blade.

Turn the handle clockwise to minor tighten blade tension and counterclockwise to release blade

tension.

A blade under tension may also pull drive wheel out of alignment. Adjust alignment of drive wheel

with tracking knob.

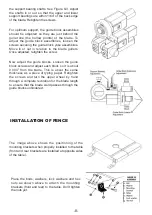

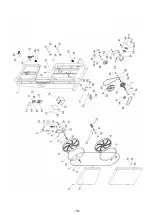

Adjusting blade support

Whenever changing a blade or adjusting tension and

tracking, the upper and lower blade support bearings

and guide blocks must be re-adjusted. Always adjust the

assemblies away from the blade before installing a new

blade or making blade tracking adjustments. After blade

tension and tracking are set correctly, re-adjust the upper

and lower support bearings and guide block assemblies into

position. See Figure 8-1 for upper blade guide and Figure 8-2

for lower blade guide.

The support bearings back-up the blade during the sawing

operation. To adjust the support bearings, loosen the screws

Содержание MI-92300

Страница 1: ...MODEL NO MI 92300 OPERATING MANUAL START STOP ON OFF...

Страница 15: ...14...

Страница 17: ......

Страница 20: ...FAULT DISPLAY...