6

46-620 B73 & Series 75 Liquid Level Switches

5b. Close shut-off valves (if so equipped) to isolate control

from tank. Drain off liquid in float chamber.

5c. On installations without shut-off valves, relieve pressure

from the tank. Drain liquid in tank to a level below the

connections of the float chamber.

NOTE: Level control, connections and pipe lines need not be

removed from the tank.

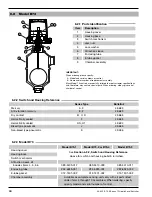

6. Loosen enclosing tube nut with a

15

⁄

16

" wrench. Unscrew

enclosing tube counterclockwise (switch and housing base

will rotate also), until it is free. Refer to

Figure 8

.

7. Lift enclosing tube, switch, and base off float chamber.

Jam nuts and attraction sleeve are now accessible.

8. Measure the distance “D” from the top edge of the upper

jam nuts to the top of the float stem. Refer to

Figure 7

.

Record this measurement.

9. Loosen and remove upper jam nuts, guide washer and

attraction sleeve.

10. Loosen and adjust lower jam nuts to the desired position.

Tighten lower jam nuts securely. Refer to

Figure 7

.

11. Replace attraction sleeve on stem.

12. Replace upper jam nuts and guide washer on the stem in

the position previously noted. Tighten upper jam nuts

securely. Refer to

Figure 7

.

NOTE: Use a new enclosing tube gasket when reassembling enclos-

ing tube to the chamber. Make certain that all gasket surfaces

are thoroughly cleaned to allow proper gasket seating. Coat

enclosing tube threads with anti-seizing compound.

13. Replace enclosing tube, switch, and base on chamber. Screw

tube clockwise until tightened to 75–100 foot-pounds of

torque for a fiber gasket or 200–225 foot-pounds

of torque for a spiral wound gasket.

14. Loosen the set screws at the base of the switch housing.

Rotate switch housing to correct position and tighten set

screws. Refer to

Figure 2

on page 3.

15. Bring supply wires through conduit outlet. Follow steps

5 through 10 in

Section 1.5, Wiring

on page 3.

16. Test switch action by varying liquid level in float chamber.

NOTE: If switch mechanism fails to function properly, check vertical

alignment of control housing and consult installation bulletin

on switch mechanism. If the unit still fails to function properly,

consult the factory.

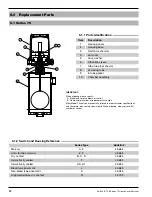

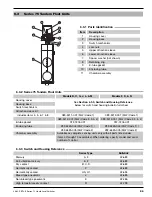

Float

Enclosing tube

Refer to Figures 6 and 7

Housing base

Enclosing tube nut

Conduit

connection

Switch housing

cover

Chamber

Figure 8