4

46-620 B73 & Series 75 Liquid Level Switches

2.0

Reference Information

2.1

Description

Magnetrol’s B73 and Series 75 level switches are float oper-

ated units suitable for use on clean liquid applications for

level alarm, pump control and safety shutdown functions.

Series 75 units are available with tandem floats for applica-

tions where widely spaced high and low switching are

required by a single control.

2.2

Theory of Operation

The design of float operated level switches is based upon

the principle that a magnetic field will not be affected by

non-magnetic materials such as 316 stainless steel. In this

case, the float moves a magnetic attraction sleeve within

a non-magnetic enclosing tube and actuates a magnetic

switch mechanism. The enclosing tube provides a pressure

seal to the chamber and therefore to the process.

2.3

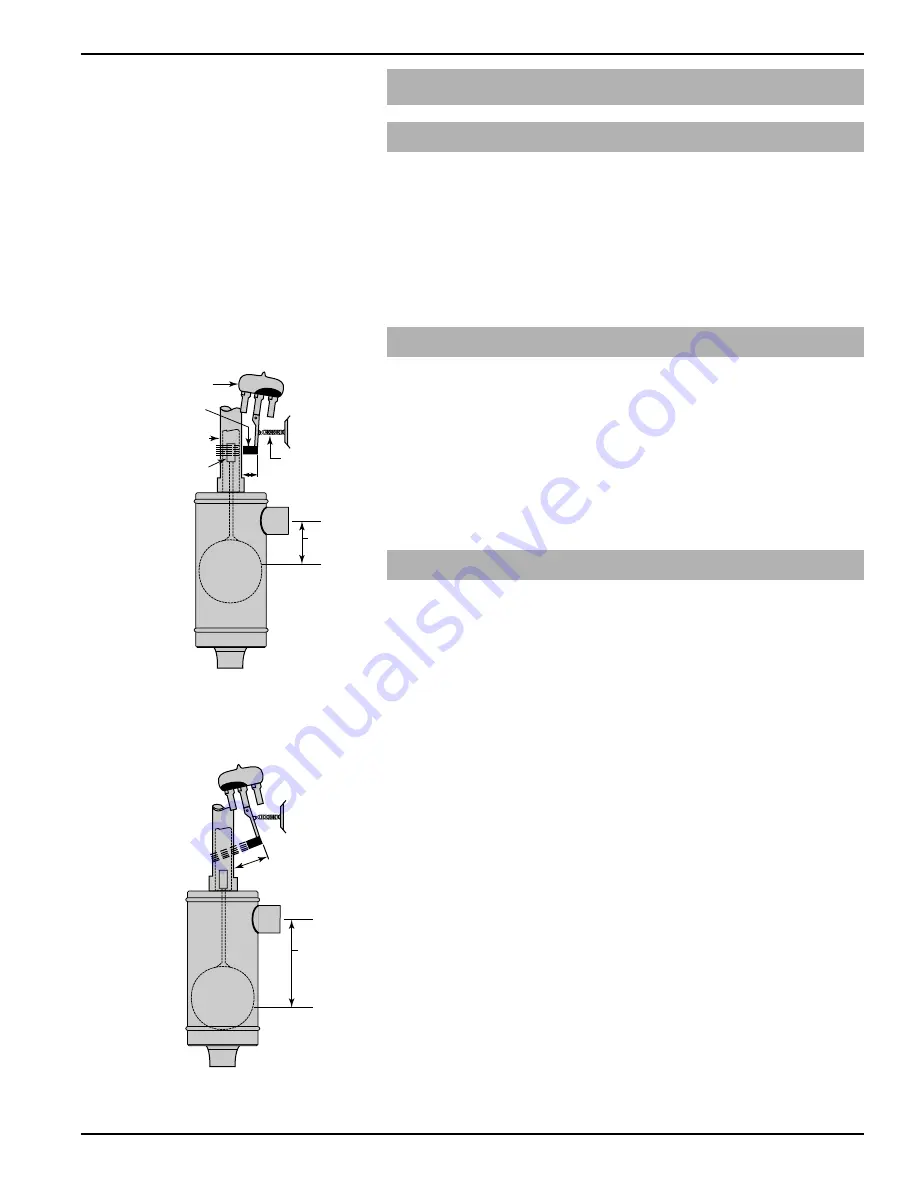

Operating Cycle

As the liquid level rises in the chamber the float moves the

magnetic attraction sleeve up within the enclosing tube

and into the field of the switch mechanism magnet.

Refer to

Figure 4

. As a result, the magnet is drawn in

tightly to the enclosing tube causing the switch to trip,

making or breaking an electrical circuit. As the liquid level

falls, the float drops and moves the attraction sleeve out of

the magnetic field, releasing the switch at a predetermined

low level. Refer to

Figure 5

. The tension spring ensures the

return of the switch in a snap action.

Tandem float units incorporate two floats which operate

independently. The lower float actuates the upper switch

mechanism, and the upper float actuates the lower switch

mechanism. The upper float is attached to the lower

attraction sleeve by means of a hollow stem. The lower

float attaches to the upper attraction sleeve with a solid

stem, which extends upward through the upper float and

stem assembly.

4

5

6

Swing in

position

Mercury switch

Return spring

Enclosing tube

(non-magnetic)

Attraction

sleeve

Magnet

HL

Figure 4

Switch Tripped

Figure 5

Switch Released

4

5

6

Swing out

position

LL