035-000049-001

Page 14

HCA IOM 1.1 8-28-2017

NOTE: Piping should be installed by a qualified install-

er familiar with the type of piping to be installed. Per-

form piping to industry best practices.

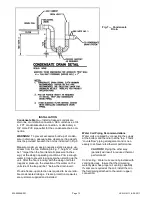

STEAM COILS — Position the steam supply connec-

tion at the top of the coil, and the return (condensate)

connection at the bottom.

Figure 8 illustrates the normal piping components

and the suggested locations for high, medium, or low-

pressure steam coils. The low-pressure application

(zero to 15 psig) can dispense with the ¼-in. petcock

for continuous venting located above the vacuum

breaker (check valve).

Note the horizontal location of the 15-degree check

valve, and the orientation of the gate/pivot. This valve

is intended to relieve any vacuum forming in the con-

densate outlet of a condensing steam coil, and to seal

this port when steam pressure is again supplied to the

coil. It must not be installed in any other position, and

should not be used in the supply line.

For coils used in tempering service, or to preheat

outside air, install an immersion thermostat in the con-

densate line ahead of the trap. This will shut down the

supply fan and close the outdoor damper whenever the

condensate falls to a predetermined point, perhaps 120

F.

NOTE: DO NOT use an immersion thermostat to over-

ride a duct thermostat and open the steam supply

valve. For vacuum return systems, the vacuum break-

ing check valve would be piped into the condensate

line between the trap and the gate valve instead of

open to the atmosphere.

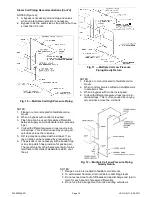

Figure 9 illustrates the typical piping at the end of every

steam supply main. Omitting this causes many field

problems and failed coils.

Figure 10 shows the typical field piping of multiple

coils. Use this only if the coils are the same size and

have the same pressure drop. If this is not the case, an

individual trap must be provided for each coil.

Figure 11 shows a multiple coil arrangement applied to

a gravity return, including the open air relief to the at-

mosphere, which DOES NOT replace the vacuum

breakers.

Figure 12 illustrates the basic condensate lift piping.

NOTES:

1. Flange or union is located to facilitate coil

removal.

2. Flash trap may be used if pressure differen-

tial between steam and condensate return

exceeds 5 psi.

3. Dirt leg may be replaced with a strainer. If

so, tee on drop can be replaced by a reduc-

ing ell.

4. The petcock is not necessary with a bucket

trap or any trap which has provision for

passing air. The great majority of high or

medium pressure returns end in hot wells or

deaerators which vent the air.

Fig. 8 — Low, Medium or High

Pressure Coil Piping

Steam Coil Piping Recommendations

GENERAL — Use straps around the coil casing to lift

and place the coil.

CAUTION

To prevent damage to the coil or coil headers:

Do not

use the headers to lift the coil.

Support the piping

and coil connections independently. Do not use the coil

connections to support piping. When tightening coil

connections, use a backup wrench on the coil connec-

tion stub-out.

Fig. 9 — End of Steam Supply

Main Piping Detail

Содержание HCA Series

Страница 2: ...035 000049 001 Page 2 HCA IOM 1 1 8 28 2017 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 26: ...035 000049 001 Page 26 HCA IOM 1 1 8 28 2017...

Страница 28: ...035 000049 001 Page 28 HCA IOM 1 1 8 28 2017 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 29: ...035 000049 001 Page 29 HCA IOM 1 1 8 28 2017 THIS PAGE INTENTIONALLY LEFT BLANK...