S600D USER AND MAINTENANCE MANUAL

54

1.

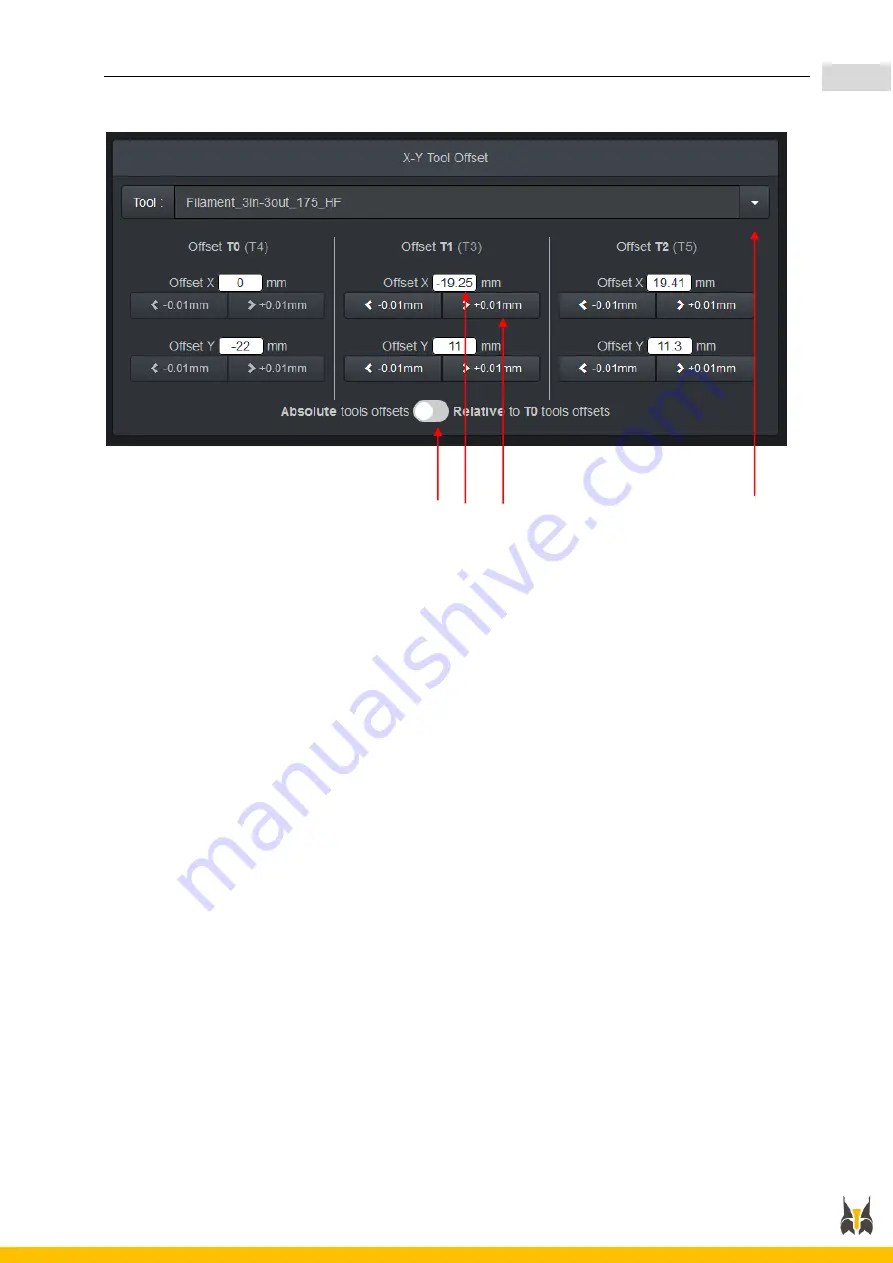

To select the toolhead to calibrate

2.

Display of XY offset values as “Absolute” (machine origin) values or “Relative” values (relative

to nozzle n°0)

3.

Field to enter and display the offset value

4.

To adjust the value in 0.01 mm increments.

Configuration required:

-

FIL33 HF toolhead

-

3x N040 nozzle

-

Layer height 0.3 mm

-

PLA in E0, E1 and E2

NOTES:

-

Before calibrating XY offsets, the machine must be calibrated (auto-delta calibration, manual

XY Tilt compensation and babystep) and the nozzles must be leveled (Nozzle height

calibration macro) and placed in position against the silicon disc to prevent leaks.

-

Materials must be pre-loaded and primed (

“

pre-load

”

then

“

prime

” macros

)

-

For a different configuration (materials, nozzles etc.) a different g-code file must be

generated.

To begin calibrating the nozzle connected to E1, import the

XY Tool offset calibration (T1).gcode

file

via the

“

G-CODE FILES

”

tab on the Web Control interface and launch the build.

(Repeat this process to being calibrating the nozzle connected to E2 and build the

XY Tool offset

calibration (T2).gcode

file).

1

2 3

4

All manuals and user guides at all-guides.com

Содержание S600D

Страница 1: ...S600D V1 1 All manuals and user guides at all guides com a l l g u i d e s c o m ...

Страница 41: ...S600D USER AND MAINTENANCE MANUAL 41 All manuals and user guides at all guides com a l l g u i d e s c o m ...

Страница 44: ...S600D USER AND MAINTENANCE MANUAL 44 230V AC 16A 50 60Hz All manuals and user guides at all guides com ...

Страница 60: ...S600D USER AND MAINTENANCE MANUAL 60 All manuals and user guides at all guides com ...

Страница 104: ...S600D USER AND MAINTENANCE MANUAL 104 All manuals and user guides at all guides com ...