DP16-1050B 09

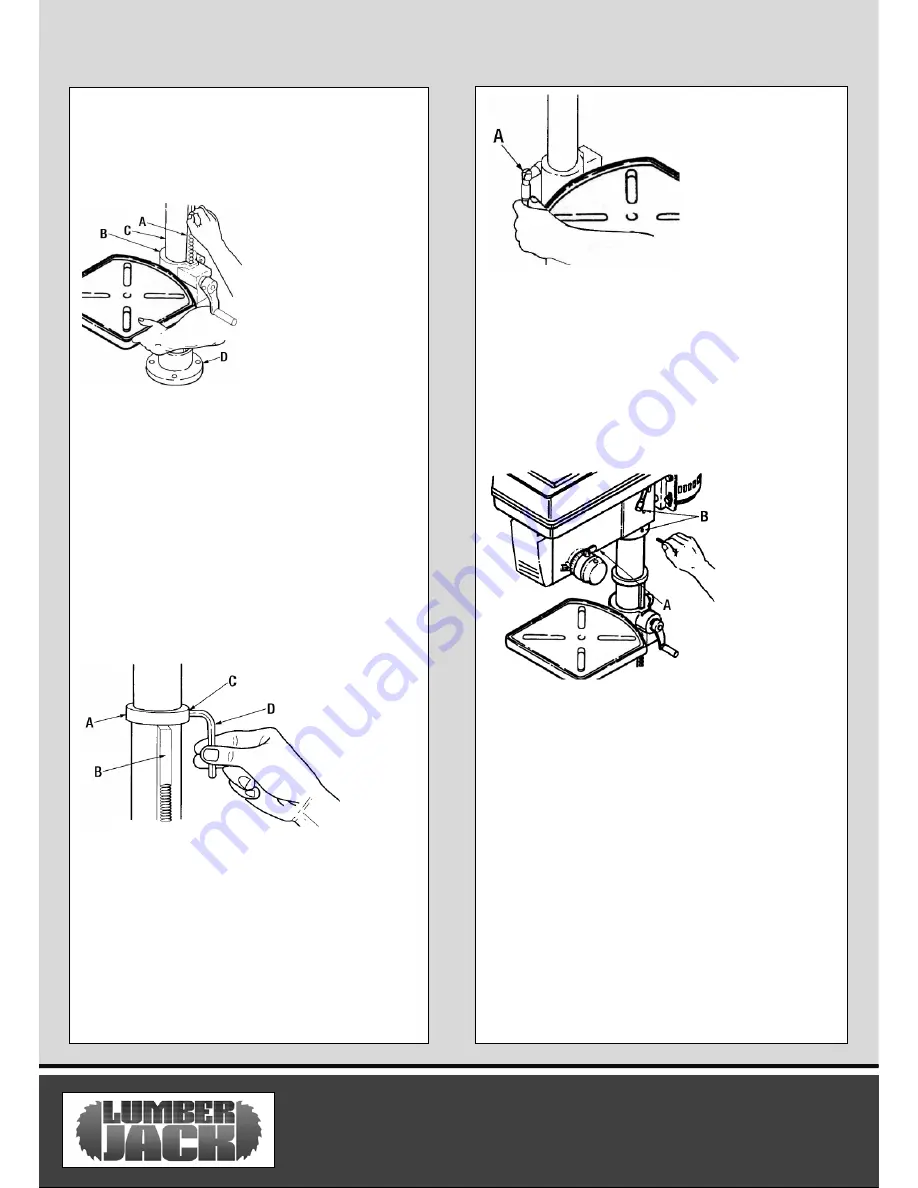

8.While holding the rack (A) and table support

(B) in an engaged position, slide both down over

the column (C). Slide rack down the column until

the rack is positioned against the lower column

support (D).

9.Replace column collar (A) and position it bevel

side down over the rack (B). Tighten set screw

(C) in collar with 3mm hex. key (D). To let the

rack slide when the table is swung to the left or

right around the column, the collar must sit

loosely over the rack and should not be angled

on the column. Only tighten set screw enough to

keep the collar in place, otherwise the collar may

break due to excessive pressure.

NOTE:

To avoid column or collar damage, do not

overtighten set screw.

10. Locate the support lock handle (A) in loose

parts bag and tighten by hand.

11. To minimize crank backlash; tighten the

support lock handle and rotate the elevation

worm shaft clockwise with the crank handle.

Loosen the set screw in the crank and reposition

it as close to the table support as possible.

Tighten set screw in the crank handle.

Installation the head

1. Remove the protective covering from the head

assembly.

2. Carefully lift the head above the column and

slide it down on the column as far as it will go.

Align the head with the table and the base.

3. Using a 4mm hex. Key, tighten the head set

screws on the right side of the head.

Installing

pulley

cover knob or locking

pulley cover

1.Install the knob (A) Fig.13B to the pulley cover

(B) using a small pan head screw (C) as shown in

Option #1.

2.For safety reasons, user may be required to lock

the pulley cover to prevent easy access to the

pulleys. This can be done by only using the small

pan head screw (C). Close the pulley cover and

screw panhead screw through the cover and into

the tab (D) as shown in Option #2.

ASSEMBLY INSTRUCTIONS