DP16-1050B 12

Adjustments

WARNING!

For your own safety, turn the switch

OFF and remove the plug from the power source

before making any adjustements. To avoid injury

from thrown parts due to the spring release,

follow instructions carefully and wear safety

glasses.

Drilling to a specific depth

To drill a blind hole (not all the way through) to a

given depth, proceed as follows.

1. Mark the depth of the hole on the workpiece.

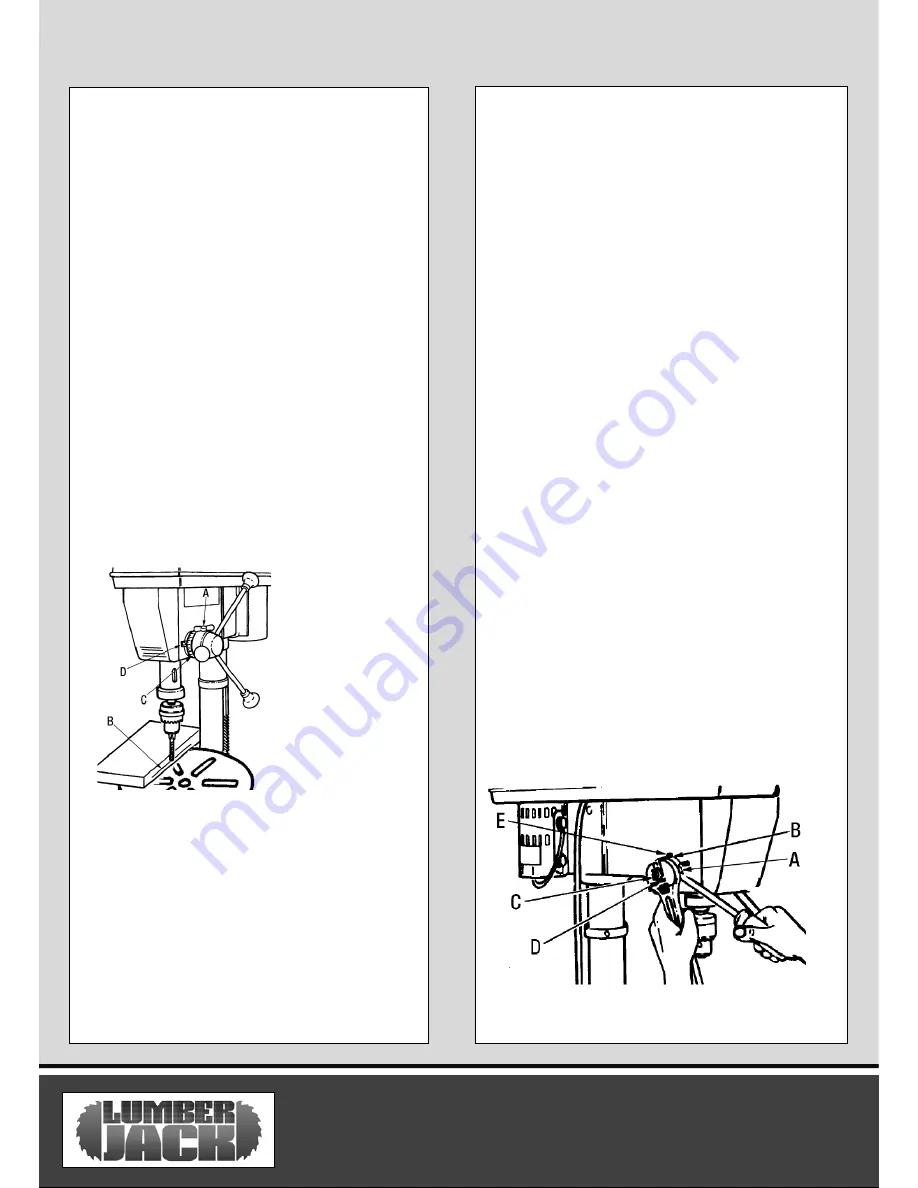

2. Loosen the depth scale lock knob (A) Fig.19.

3. With the switch OFF, bring the drill bit down

until the tip of the lips of the drill bit are even

with the mark (B).

4. Turn the depth scale (C) counterclockwise

until it stops moving.

5. Tighten the depth scale lock knob.

The drill bit will stop at this depth until the depth

scale is readjusted.

Another way-depth scale

1. With the power OFF, loosen the depth scale

lock knob (A) Fig.19.

2. Place workpiece on table. Adjust table until

the tip of the drill is just a little above the top of

the workpiece.

3. Turn the depth scale (C) clockwise until the

depth scale indicator (D) points to the desired

drilling depth on the scale.

4. Tighten the depth scale lock knob.

5. The chuck or drill will now be stopped after

traveling downward the distance selected on the

depth scale.

Quill return spring

NOTE: The return spring tension is set at the

factory and should not require further

adjustment.

1. With the chuck at its highest possible position,

turn the depth scale (C) clockwise until it stops and

tighten the depth scale lock knob (A). This will

prevent the quill from dropping while tensioning

the spring.

2. Lower the table for additional clearance.

3. Work from the left side of the drill press.

4. Place screwdriver in the lower front notch (A)

of the spring cap (B), and hold it in place while

loosening and removing the outer nut (C) (only).

5. With screwdriver remaining in the notch, loosen

inner nut (D) (approx. 1/8”) until the notch

disengages from the boss on the head. Do not

remove this nut.

6. Carefully turn screwdriver counterclockwise and

engage the next notch (E) in the boss. Do not

remove screwdriver.

7.

Tighten nut with wrench only enough to engage

boss. Do not over tighten as this will restrict quill

movement.

8. Check tension while turning feed handles.

9.If there is not enough tension on the spring,

repeat steps 4-8 moving only one notch each time

and checking tension after each repetition.

ADJUSTMENTS