Seite 17

19. Technical data

19. Technical data

20. Type testing / Quality certification

20. Type testing / Quality certification

Tabe 4

the stove type thermoInsert made by lohberger, which is independent of in-

door air, was successfully tested in compliance with the following standards:

•

DIn en 13240 (room heating appliance for solid fuels)

•

DIn en 13229 (fireplace inserts including open fireplaces using solid fuels)

•

approval principles for the testing and assessment of fireplaces for solid

fuels that are independent of indoor air, DIBt Berlin (germany)

•

agreement according to art. 15a B-Vg (austrian law) regarding the preventive

measures for small-scale heating appliances.

the test was carried out at the tÜV-sÜD in Munich (germany).

in addition the following requirements are met

•

austrian environment label uZ37

•

the stringent requirements of the (swiss) quality certification “Holzenergie

schweiz” for wood-burning fireplaces in residential areas

• regulations of the “Bundes-Immissionsschutzgesetz” – 1st BlmSchV – 2nd

level (german law to provide emission control)

amongst others the following exhaust gas limits according to the following

german standards are complied with: regensburger norm, stuttgarter norm

and Münchner Verordnung.

TÜV Test report number:

W-O 1190-0008

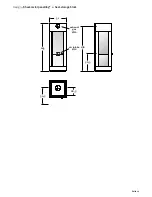

Dimensions (installation dimensions)

Width x height x depth

cm

44 x 49 x 125

with panelling (optional)

Width x height x depth

cm

51 x 50,5 x 128,5

Flue gas connection

Diameter

cm

12

Combustion air connection

Diameter

cm

10

Fuel filling door opening

Width x height

cm

27,5 x 28,8

Fuel filling space

Width x height x depth

cm

31 x 35,5 x 27

Fuel filling height

Insert stove

cm

ca. 15

Fuel consumption

at rated heat output

kg / h

ca. 1,9

Heating time max.

at rated heat output

h

ca. 1

ash drawer

Insert stove

liter

3,5

Weight (without packaging)

Insert stove

kg

ca. 110

with panelling (optional)

Decorative glass inlay

kg

ca. 145

with panelling (optional)

Decorative tile inlay

kg

ca. 170

output data

Data for chimney calculation (according to DIn 4705)

rated heat output

Wood

kW

7,1

Flue gas temperature

Wood

°C

240

Flue gas mass flow rate

Wood

g/s

7,1

required discharge pressure

at rated heat output

pa

10

Specifications „Customer-supplied panelling“

required minimum cross-sections

supply air grille

cm2

770

exhaust air grille

cm2

1340

Minimum thickness of insulation

to adjacent wall

cm

9

to the ceiling

cm

12

Minimum clearances

Flue air grille to ceiling

cm

52

appliance to convection air casing

cm

15