14

Always empty the hopper before any maintenance is carried out

7.1 - DAILY

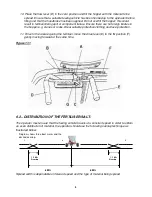

1. Check the condition of the engagement mechanism and grease daily. Use the following

procedure, firstly engage the drive, and then pump grease into the nipple.

2. Check the condition of the spreader, if any parts need replacing this should be carried

out before operating the machine.

3. Check tyre pressures before use.

4. Check all nuts and bolts are secure before operating.

5. Check the condition of the swivel hitch bushes and replace if damaged or worn

excessively.

6. Check the tension on drive chain and lubricate when necessary (LDS700 Only)

7. Always wash the spreader thoroughly after use, spray a CORROSION INHIBITOR over

the spreader disc and axle components to prevent corrosion. (LDS120DS version, see parts

list)

MAINTENANCE

7

Содержание LDS120

Страница 1: ...LDS120 120DS 240 360 700 OPERATORS MANUAL WM1 LDS120 LDS GROUND DRIVE SPREADER...

Страница 15: ...13 LDS SPREADER SETTINGS CHART MATERIAL TOWING VEHICLE OPERATING SPEED mph SPREAD WIDTH m FEED GATE SETTING...

Страница 18: ...16 8 1 MAIN FRAME AND PARTS PARTS LIST LDS120 LDS120DS 8...

Страница 21: ...19 8 4 MAIN FRAME AND PARTS PARTS LIST LDS 240 360 8...