8

Units with anti-tipping rollers should be adjusted to pro-

vide 1/8” maximum gap between the bottom of the

beam and the roller. Run the trolley the length of the

beam to check for tight places. Readjust if needed.

On geared trolleys, the bottom of the hand chain loop is

normally located two feet (0.6M) above the floor. If it is

desired to change this, find the unwelded link and open

it by spreading with a chisel or twist one end with a

wrench while holding the other end in a vise or another

wrench. Remove an even number of links (2,4,6, etc.) as

necessary to shorten the chain or add an even number of

links to lengthen the chain (when lengthening the chain,

another open link will be required and this can be made

from a welded link by cutting through weld with a hack-

saw). Make certain that the chain is not twisted–then re-

install and close open links.

NOTE:

AFTER THE UNIT IS CONNECTED TO THE

AIR SUPPLY SYSTEM (SEE BELOW), SUS

PEND A CAPACITY LOAD FROM THE HOIST

AND OPERATE THE TROLLEY OVER THE

ENTIRE LENGTH OF THE RUNWAY OR MONO

RAIL SYSTEM TO BE SURE THAT THE ADJUST

MENTS AND OPERATION IS SATISFACTORY.

ON SYSTEMS WITH CURVES,THE EDGES OF

THE RAIL AT THE CURVED SECTIONS SHOULD

BE KEPT LIGHTLY LUBRICATED WITH GREASE.

INSTALLING MUFFLER

Install the 3” long 1 1/4” NPT pipe nipple through the

hole in the motor end cover and thread it into the valve

exhaust port. Install the 1 1/4” NPT pipe elbow onto the

end of the pipe nipple. Tighten the elbow until it faces

downward. Install the muffler into the elbow and tight-

en.

!

WARNING

An excessively worn beam flange may fail and allow

the trolley to fall from the beam.

TO AVOID INJURY:

Periodically inspect the beam flange for wear. Replace

beam if flange is worn.

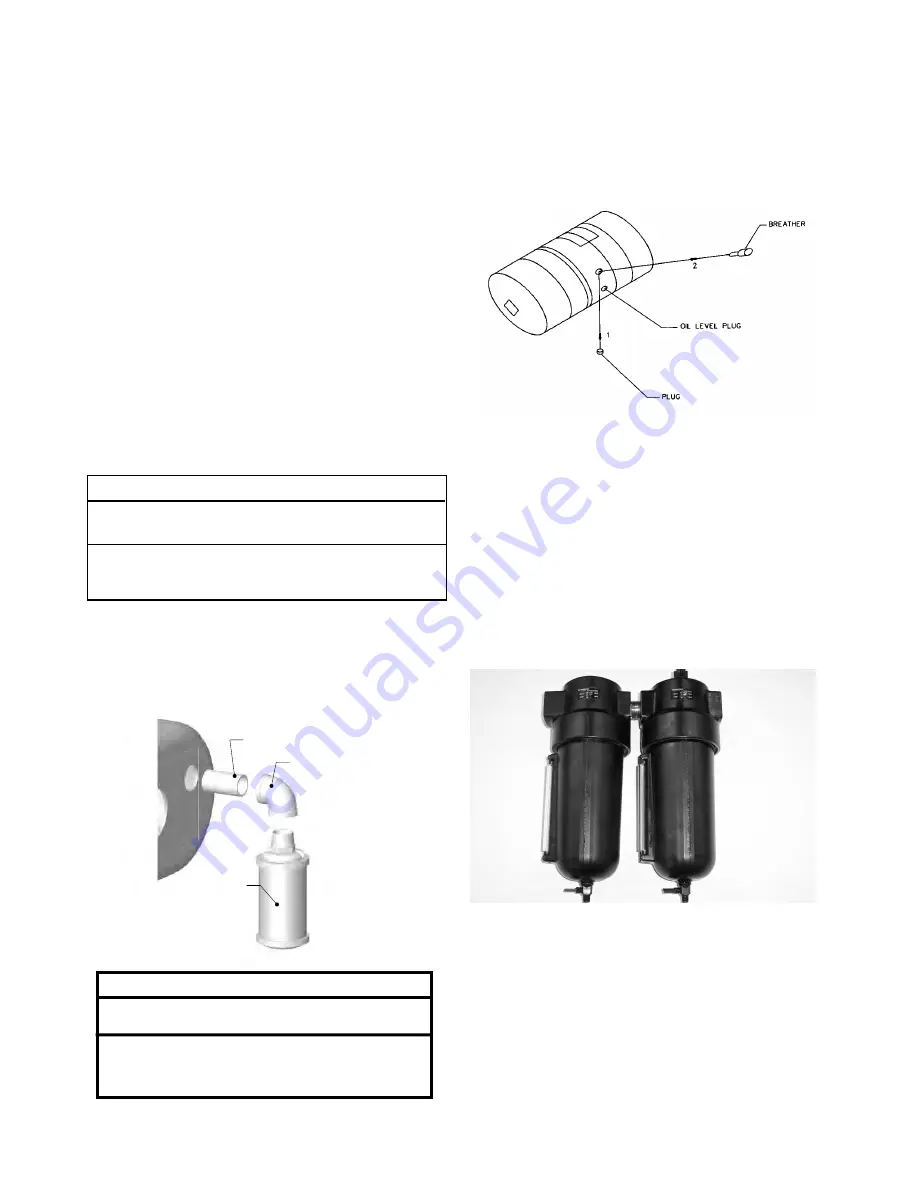

INSTALLING BREATHER

After the hook suspension is assembled to the hoist or after the

hoist and trolley are mounted on the beam, remove the upper

plug from the main housing (652-110) and install the breather

(inside information envelope). Failure to install the breather

could damage oil seals and thus cause oil leaks.

AIR SUPPLY SYSTEM

Connect the hoist to a filtered and lubricated air source

using a 1” (25.4 mm.) I.D. hose (see Figure 3). Do not use

smaller diameter hose, since it will restrict air flow and

reduce hoist performance. If the hoist is suspended from a

trolley, provide sufficient hose to reach from the source to

the farthest point of trolley travel. Hose Trolleys are rec-

ommended to keep the hose up and out of the way.

A filter and lubricator (see Figure 3)

must

be installed

between the air source and the air hose leading to the

hoist. These keep the air flowing free from dirt and add

lubricant to the air so internal parts of the motor are con-

stantly lubricated. Use a good grade of air powered tool

oil or SAE 10W machine oil. Such oil can be obtained from

CM

®

, Coffing, or Budgit.

The recommended operating air pressure for the hoist is

90 psig. When line pressure exceeds 100 psig (at the hoist

when it is lifting rated load), it is recommended that a

pressure regulator be provided in the air supply line to

keep the pressure at 90 psig. Although there is a wide

range of pressures within which the hoist will operate,

motor efficiency decreases as the air pressure drops.

Excessive moisture in the air line may cause rust or ice to

form in the muffler when air expands as it passes through

the motor. Install a moisture separator in the air line and

an after cooler between compressor and air receiver to

help prevent moisture problems.

INSTALL

BREATHER

Figure 3. Filter and Lubricator Unit

!

WARNING

Operating hoist without muffler can cause hearing

loss.

TO AVOID INJURY:

To avoid injury, only operate hoist with muffler

securely attached.