13

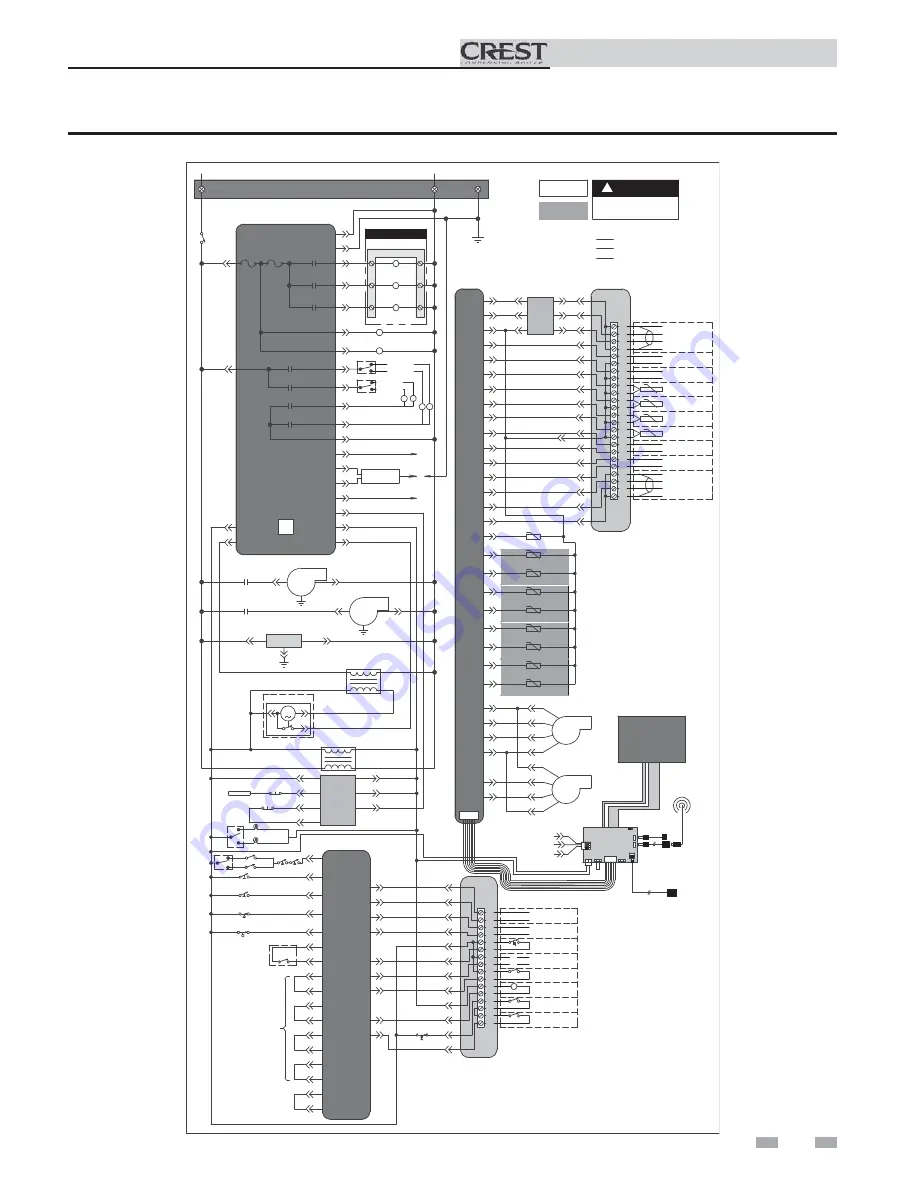

Dual Fuel Supplemental Manual

PRE-MIX SENSOR 1 (S11)

FLUE SENSOR (S10)

FLUE SENSOR

OUTLET SENSOR (S1)

-T

-T

-T

-T

-T

-T

-T

-T

PRE-MIX SENSOR 2 (S14)

PRE-MIX SENSOR 2 (S12)

PRE-MIX SENSOR 1 (S13)

OUTLET SENSOR (S9)

1.5A EACH MAX

WARNING

OUT

100267529 REV A

JUNCTION BOX

TERMINAL STRIP

120V SUPPLY "L"

TERMINAL STRIP

120V SUPPLY "N"

120VAC

NEUTRAL

INTEGRATED CONTROL

ON/OFF

SWITCH

F2

3.15 A

F4

5.0 A

SYSTEM PUMP

RELAY

BOILER PUMP

RELAY

DHW PUMP

RELAY

X1-1

X1-2

X1-4

X1-8

X2-4

SMALL BLOWER RELAY

LARGE BLOWER RELAY

SMALL GAS

VALVE RELAY

LARGE GAS

VALVE RELAY

X1-6

2

-

0

1

X

1

-

0

1

X

X10-3

SMALL GAS

VALVE RELAY

LARGE GAS

VALVE RELAY

X10-6

X10-5

X10-4

TERMINAL STRIP

SYSTEM PUMP

CONTACTOR

BOLIER PUMP

CONTACTOR

DHW PUMP

CONTACTOR

SMALL BLOWER

RELAY

LARGE BLOWER

RELAY

SMALL BLOWER

LARGE BLOWER

X6-10

X13-4

X6-1

X2-5

2

1

3

2

1

3

BAS

X1-1

X1-2

X1-3

FLUE DAMPER

TRANSFORMER

1

2

3

24V

TRANSFORMER

FLUE DAMPER

X6-3

X1-12

X1-3

LWCO

BOARD

TEST

SWITCH

LWCO

PROBE

LWCO RESET

J3-6

J3-3

J2-1

J2-2

J3-5

J3-2

J3-4

X6-5

X6-15

X6-12

X13-1

X6-6

X3-3

X3-4

X3-1

X3-2

X6-11

X6-2

X6-14

INTEGRATED

CONTROL

BLOWER PROVING

SWITCH (LARGE)

BLOWER PROVING

SWITCH (SMALL)

BLOCKED FLUE

SWITCH

BLOCKED DRAIN

SWITCH

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

ALARM

CONTACTS

RUN-TIME

CONTACTS

TANK

THERMOSTAT

LOUVER

PROVING

24 VAC LOUVER

RELAY COIL

AUX

SWITCH 1

AUX

SWITCH 2

ENABLE

R

W

SMALL

CONNECTION BOARD

CN1-4

CN1-5

CN1-6

CN1-12

CN1-10

X6-13

X6-4

CN1-11

CN1-9

CN1-8

CN1-7

CN1-1

CN1-2

CN1-3

HIGH LIMIT

SWITCH

X1-3

X1-7

X1-10

X2-5

FLAME

SENSE 2

FLAME

SENSE 1

SPARK

GENERATOR

SPARK

ROD

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

SHIELD

SHIELD

A

B

MODBUS

OPTION

+

-

-

+

RATE

X6-17

BOILER

PUMP OUT

SYSTEM RETURN

SENSOR

SYSTEM SUPPLY

SENSOR

0-10V

0-10V

TANK

SENSOR

OUTDOOR

SENSOR

+

+

-

-

0-10V

0-10V

BMS

IN

SYSTEM

PUMP IN

SHIELD

SHIELD

A

B

CASCADE

LARGE

CONNECTION BOARD

CN6-1

CN3-6

CN3-7

CN3-14

CN3-13

CN3-11

CN3-9

CN3-8

CN3-1

CN3-2

CN3-3

CN3-4

CN6-2

CN6-3

CN3-10

CN3-12

BAS

X4-1

X4-2

X4-3

X6-3

X6-1

X6-2

X8-20

X8-10

X7-8

X8-13

X8-14

X8-12

INTEGRATED

CONTROL

X8-5

X8-15

X7-7

X8-11

X8-6

X8-16

X8-7

X8-17

X8-1

-T

INLET SENSOR

X8-3

X8-8

X8-2

X8-4

X8-9

X7-1

X7-5

X7-2

X7-6

GROUND

X6-18

X6-9

M

X6-8

X13-2

X13-3

1

2

4

5

1

2

4

5

SMALL BLOWER

LARGE BLOWER

X11

X4

X5-1

X5-7

X5-2

X5-8

X5-3

X5-9

X5-4

X5-10

X5-5

X5-41

X5-6

X5-12

HIGH VOLTAGE

LOW VOLTAGE

OPTIONAL ITEMS

DUAL SENSOR

DISCONNECT POWER

non-repairable damage to the integrated controller or other components.

BEFORE SERVICING

CN6-2

3. Actual connector block locations may vary from those show n on diagrams. Refer to actual components for proper connector blo ck

SINGLE HOUSING

120 VAC

locations when using diagrams to troubleshoot unit.

USB

INTERFACE

"X5"

BLOCK WIRING

IS MODEL

DEPENDANT

CAM

SWITCH

PROPANE LIGHT

NATURAL LIGHT

NATURAL LGPS

PROPANE LGPS

CAM SWITCH

GPS2 GPS3

PROPANE

NATURAL

PROPANE

NATURAL

CN3-4

X8-1

OPTIONAL

ETHERNET CABLE

E

GND

WIFI

DONGLE

RIBBON CABLE

SW1

J2

8

43

J6

J9

J17

J23

J12

J11

LG CON BRD

J8

LCD

DISPLAY

USB CABLE

OPTIONAL USB/WIFI

EXTENSION CABLE

J10

J7

BAS

CN6-1

CN6-3

24V

Notes:

1. All wiring must be installed in accordance with: local, state, provincial and national code requirements per either N.E.C. in USA or

C.S.A. in Canada.

2. If any original equipment wire as supplied with the appliance must be replaced, it must be replaced with wire having same wi re gauge

(AWG) and rated for a minimum of 105°C. Exceptions: Replac ement high voltage spark lead and ribbon cables must be purchased

from the factory. Use of a non-approved spark lead or ribbon cables can lead to operational problems which could result in

BOX DEPICTS

BOX DEPICTS

!

3

Diagrams

(continued)

Figure 3-2 Ladder Diagram_2.5 - 3.5 Models

Содержание CREST 2.5

Страница 18: ...Dual Fuel Supplemental Manual Notes 18 ...

Страница 19: ...19 Dual Fuel Supplemental Manual Notes ...