TROUBLESHOOTING

If a problem occurs, check the following.

If the problem persists after checking the items in the table below, contact your nearest “LOBSTER”

dealer or direct to us.

In making any enquiries about this product or requests for repair work, first check the

troubleshooting items below, and then make a note of the model number, the usage conditions and

the trouble symptoms in as much detail as possible. If you can provide this kind of information, it

will contribute to reducing the amount of time required for delivery or repairs to be completed.

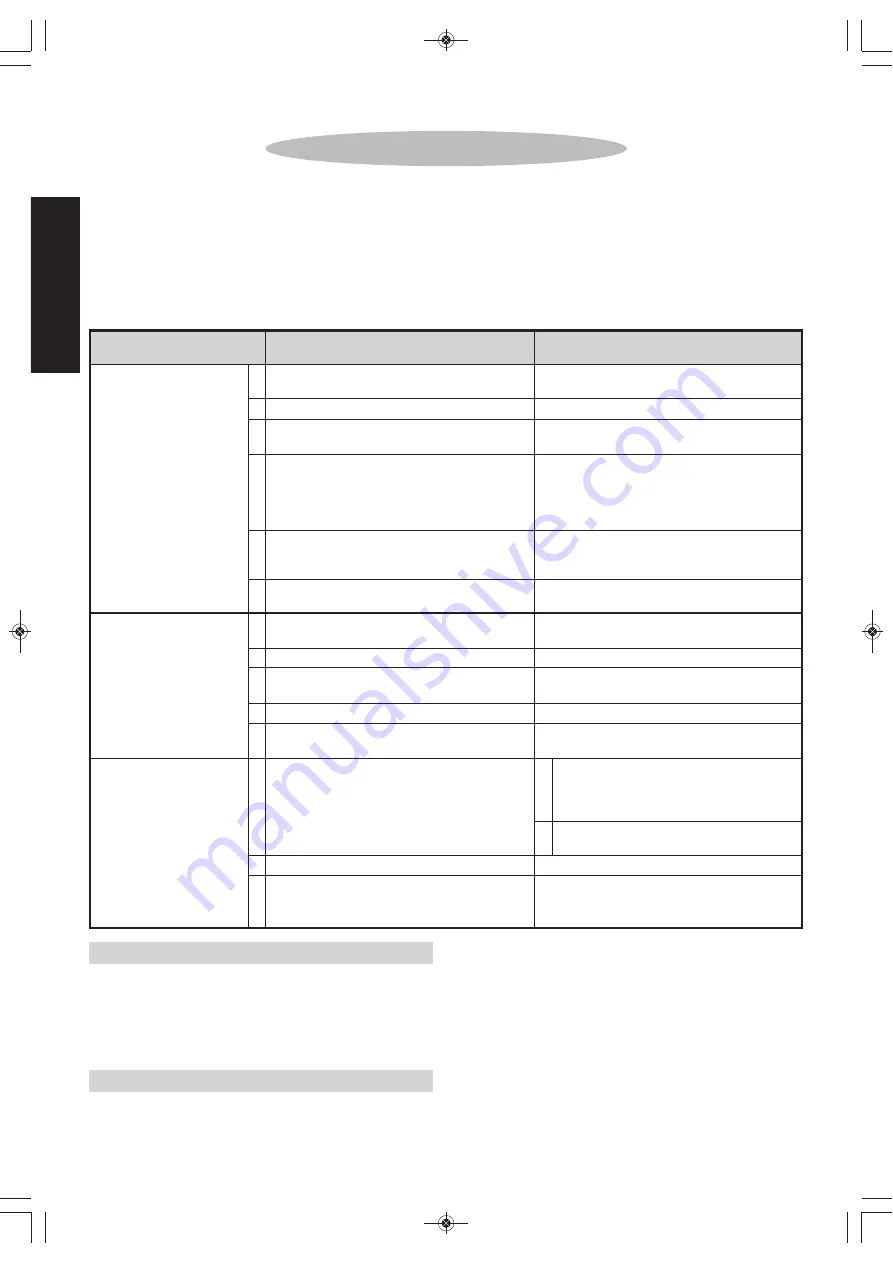

The rivet does not go

in, or the cut mandrel

does not come out

after riveting.

Number of switch

operations increases

before riveting is

complete.

Piston does not

operate, or returns

very slowly, or

operation is not

smooth.

Incorrect combination of replacement parts

being used.

Nosepiece or frame head is loose.

Jaw case is incorrectly assembled.

Contact surfaces between the jaws and the

jaw case head are not smooth.

The inside of the cylinder is dirty so that the

air piston cannot return to its proper position.

Oil filling was not performed correctly, so that

there is excess hydraulic oil inside the tool.

The rivet length is not correct for the

workpiece thickness.

Compressor air pressure is incorrect.

Jaw case is incorrectly assembled.

Jaws are worn.

Insufficient hydraulic oil, causing a shorter

stroke.

Spool is not moving properly.

Air outlet hole muffler is blocked.

The inside of the cylinder is dirty so that the

air piston cannot return to its proper position.

1

2

3

4

5

6

1

2

3

4

5

1

2

3

Replace with the correct part which matches

the rivet size. (Refer to page 7.)

Use a spanner or similar to tighten securely.

Check the jaw case setting position. (Refer to

pages 9 and 10.)

Clean the jaws and inside the jaw case head,

and apply “LOBSTER” brand jaw lube (or

spray-type lubricating oil or the accessory

hydraulic oil) to the backs of the jaws. (Refer

to pages 9 and 10.)

Clean inside the cylinder, and apply grease

inside the cylinder and to the O-ring. (Refer to

pages 11 and 12.)

Loosen the bleed plug to allow the excess

hydraulic oil to drain out. (Refer to page 12.)

Use rivets which match the workpiece

thickness.

Check the air pressure.

Check the jaw case setting position. (Refer to

page 10.)

Replace the jaws. (Refer to page 9.)

Add hydraulic oil. (Refer to page 14.)

Remove the rear part of changeplug (refer

to page 13) and push the spool 2~3mm

with a plastic (soft) stick. In case of no

improvement, take the

II

measure.

Clean the spool and apply grease to the O-

rings. (Refer to page 13.)

Replace the muffler. (Refer to pages 11 and 12.)

Clean inside the cylinder, and apply grease

inside the cylinder and to the O-ring. (Refer to

pages 11 and 12.)

Trouble

Cause

Countermeasure

“LOBSTER” brand Hydraulic Oil is supplied in a plastic filler

bottle with the tool, and can also be obtained from your “Lobster”

dealer or agent in your town. If this is not possible, a good quality

mineral oil with the following properties should also be used.

Viscosity ISO

: VG46

Viscosity Index

: 113

Viscosity at 40°C

: 46 c.s.t.

Viscosity at 100°C : 7.06 c.s.t.

Flash Point

: 228

RECOMMENDED OILS are:

Shell Tellus No. 46

Esso Teresso No. 46

Mobil D.T.E. 25 Oil (Medium)

I

II

15

英語/E

N

G

L

ISH

ULTRA JAWS (AR2000M

(A)

/AR2000H

(A)

)

The AR2000M

(A)

and AR2000H

(A)

use ultra jaws which

have greater durability. Be sure to specify “Ultra jaws

M” (AR2000M

(A)

) or “Ultra jaws H” (AR2000H

(A)

) as

replacement parts for these models.

HYDRAULIC OIL REQUIREMENTS

Use only clean hydraulic oil, as the viscosity of the oil used will

affect tool performance.

AR-2000S-M-H(A)取扱(GB):AR-2000S̲M-H(A)取扱(GB) 14/08/27 13:55 ページ 15