11.

q

Place the swashplate on the universal ball on top of the upper bearing block so that the

middle swashplate arm is opposite the fore/aft control arm. Snap the ball-links onto the

two opposed arms of the swashplate as shown.

12.

q

Check the tilting motion of the swashplate. It should seat against the plastic universal ball

on the upper bearing block, and tilt easily in any direction. If the swashplate does not seat

against the universal ball, unsnap the ball-joints, screw them each down ½ turn and

reassemble. If, on the other hand, the swashplate is too tight against the universal ball,

unsnap the ball-joints, unscrew them each ½ turn and reassemble. Repeat either

process until the swashplate rests against the universal ball and moves freely. Note that

both L-links must be the same length to prevent the swashplate from binding.

13.

q

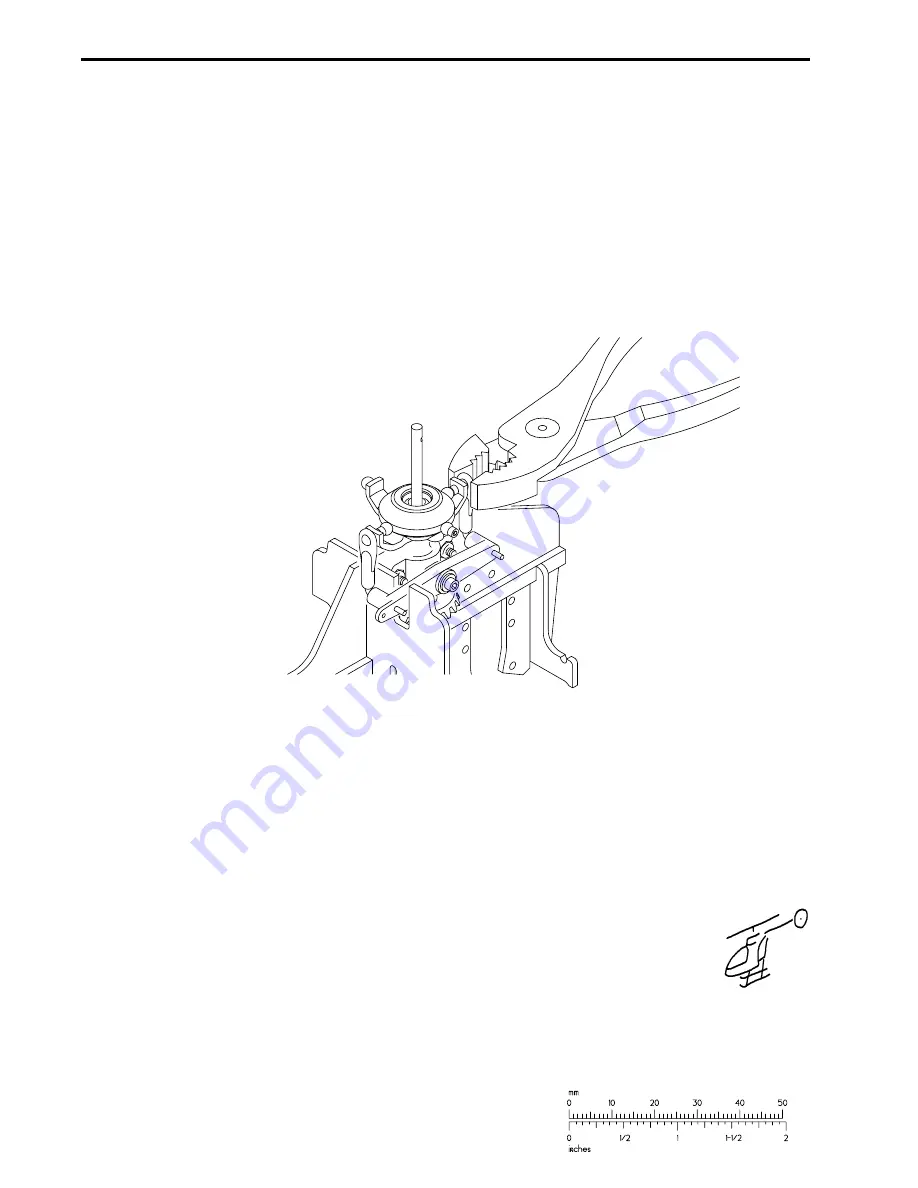

The plastic balls on the swashplate arms may be slightly larger than metal balls. If the

ball-joints are too tight, the swashplate may not operate smoothly. To get an idea of the

proper fit, snap a spare ball-link onto one of the metal universal balls on the swashplate

and move the link around. To loosen a tight ball-link on a plastic ball, gently squeeze the

ball-link with a pair of pliers as shown in Fig. 8-4 to deform the ball-link slightly. Be

careful, you can easily crush the ball-link if it slips off the ball.

Construction Manual

Swashplate

8-4

LITE MACHINES

Squeeze ball-links

GENTLY with pliers

Figure 8-4.