Note:

Each servo on the

Model 110

requires a servo wheel having a particular arm radius

(the distance from the arm center to one of the arm holes) in order to produce a

certain amount of pushrod travel. A large arm radius produces more pushrod travel

than a small radius. For each servo, select a servo wheel having arms with holes as

close as possible to the radius specified in the text. Place the wheel on the servo

output shaft so that one of the arms is angled as in the drawings, then trim off all the

other unused arms on the wheel. If you do not have a wheel with holes at the required

radius, drill a hole at the desired radius in any wheel you may have.

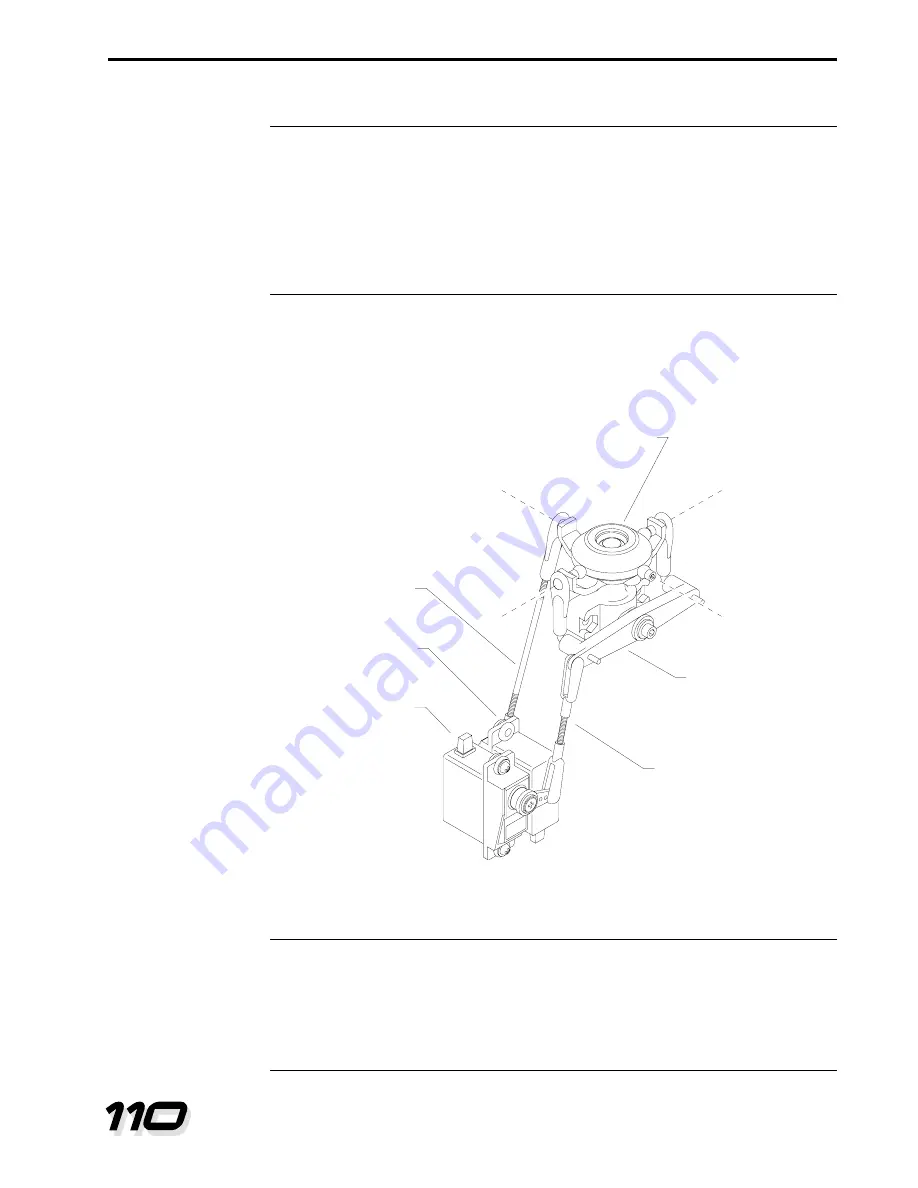

6.

q

Find two servo wheels with holes at a radius of .44" to .47” (11mm to 12mm). Fit the

wheels to the left/right and fore/aft cyclic servos at the angles shown in Fig. 14-4. Trim all

unused arms off the wheels. Secure the servo wheels to the servos with servo wheel

screws (with the arms oriented as shown).

Note:

The angle between a pushrod and a servo arm (measured when the servos are

centered) affects pushrod motion. A pushrod that is 90 degrees to a servo arm will

travel the same distance in both control directions. A pushrod at an angle other than

90 degrees will travel more in one direction than the other. This effect is called

“differential throw”. Differential throw is useful on controls that need to move more in

one direction than in the other (such as the tail rotor).

Construction Manual

Pushrods and Radio Adjustment

LITE MACHINES

14-5

Left/right cyclic

pushrod

Left/right cyclic

servo

Fore/aft cyclic

servo

Swashplate

Pitch control arm

Fore/aft cyclic

pushrod

Level

Level

Figure 14-5.