HSLG OPERATOR INSTALLATION GUIDE

- 8 -

ELECTRICAL CONNECTION AND ADJUSTMENTS

All LINEAR gate operators are supplied with a power disconnect switch to turn on and off the power supply available to the

operator. Incoming power should be brought into the operator and connected to the labeled pigtails in the disconnect box

following wiring specifi cations on page

4

. A wiring connections print can be found on the inside cover of the operator.

Proper thermal protection is supplied with the operator. The motor contains a thermal overload protector to protect from

overheating the motor due to overload or high-frequency operation. This overload will automatically reset after the motor

cools down.

LIMIT NUT ADJUSTMENTS

The limit nuts are not preset at the factory and must be adjusted for the length of the gate the operator is installed on. The

limit switches are activated by two threaded nylon rotary limit nuts which are attached to a threaded shaft and driven by chain

and sprockets from the main drive shaft. Remove the cardboard fi ller before attempting to adjust the limit nuts.

With the gate connected to the gate operator in a mid-travel position, and the power disconnect switch turned

OFF

, discon-

nect the operator by using the manual disconnect lever. Instructions for the manual disconnect can be found in the individual

operator owner’s guides. Once the operator has been disconnected, manually move the gate by hand to within a foot of its

fully open position (the foot of distance is necessary to allow for coasting of the operator after the limit switch is tripped).

Once the gate is in this position, adjust the open limit nut until it activates the limit switch for open,

LSO-1

. Press down on

the detent plate and rotate the nut along the threaded shaft. Refer to the illustration below for additional details.

Once the open limit nut is set, repeat the above process for the close direction nut and the

LSC-1

limit switch.

After fi nishing the initial limit nut adjustments, reposition the gate to approximately its center of travel. Re-engage the operator

and turn the power disconnect

ON.

Stand clear of any moving parts and press the

OPEN

button on the three-button station.

If the gate begins to close instead of open, press the

STOP

button immediately. Find the dip switch block on the main control

board and switch the hand of operation (dip switch #4, see page

9

) and try to open the gate again. Observe the gate as it

runs through a complete cycle in both directions, and adjust your limits again if necessary. Fine levels of adjustment can also

be achieved by adjusting a few teeth on the nut at a time. If the gate stops in mid travel, the open or close current sensor

adjustment or the maximum run timer may need adjustment (see page

11

).

Power supply must be of correct voltage and phase.

Always disconnect power from operator before servicing.

Keep clear of gate during operation.

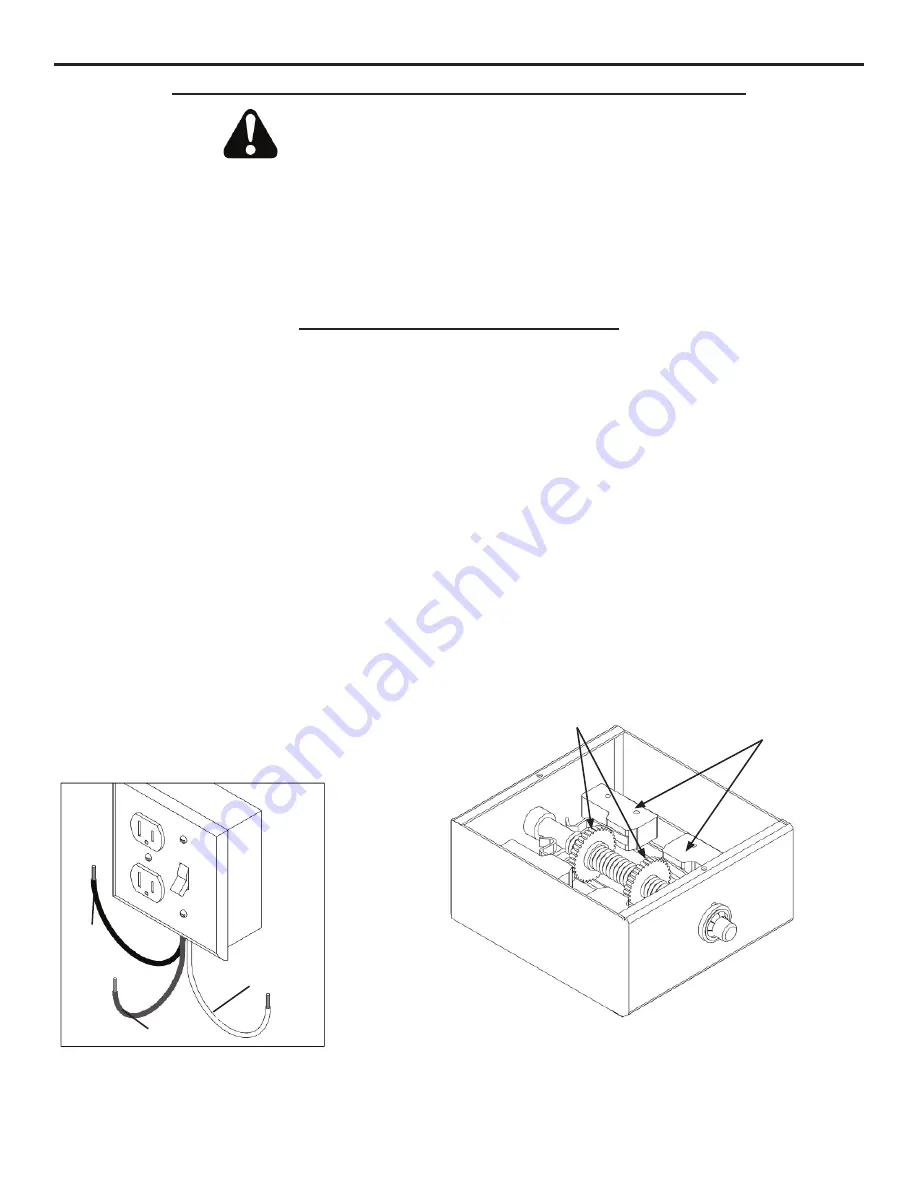

POWER DISCONNECT BOX

(115VAC VERSION SHOWN)

L1

(WHITE)

L2

(BLACK)

GROUND

(GREEN)

ON A RIGHT-HAND OPERATOR:

OPEN LIMIT SWITCH IS THE ONE CLOSER

TO THE FRONT OF THE OPERATOR. ON A

LEFT-HAND OPERATOR, THE OPEN LIMIT

SWITCH IS THE ONE FURTHEST AWAY

FROM THE FRONT OF THE OPERATOR.

LIMIT SWITCHES

LIMIT NUTS

ROTARY LIMIT BOX ASS’Y

(SWITCHES AND BOX MAY

LOOK SLIGHTLY DIFFERENT

DEPENDING ON MODEL)

Содержание HSLG

Страница 14: ...HSLG OPERATOR INSTALLATION GUIDE 14 CONTROL and ACCESSORY CONNECTION ILLUSTRATIONS...

Страница 15: ...HSLG OPERATOR INSTALLATION GUIDE 15 CONTROL and ACCESSORY CONNECTION ILLUSTRATIONS...

Страница 16: ...HSLG OPERATOR INSTALLATION GUIDE 16 CONTROL and ACCESSORY CONNECTION ILLUSTRATIONS...

Страница 17: ...HSLG OPERATOR INSTALLATION GUIDE 17 CONTROL and ACCESSORY CONNECTION ILLUSTRATIONS...

Страница 23: ...HSLG OPERATOR INSTALLATION GUIDE 23 TRACK GATE ILLUSTRATION...

Страница 25: ...HSLG OPERATOR INSTALLATION GUIDE 25 MODEL HSLG MECHANICAL PARTS EXPLODED VIEW...