12

LTC3729

sn3729 3729fas

APPLICATIO S I FOR ATIO

W

U

U

U

When using the controller in very low dropout conditions,

the maximum output current level will be reduced due to

internal slope compensation required to meet stability

criterion for buck regulators operating at greater than 50%

duty factor. A curve is provided to estimate this reduction

in peak output current level depending upon the operating

duty factor.

Operating Frequency

The LTC3729 uses a constant frequency, phase-lockable

architecture with the frequency determined by an internal

capacitor. This capacitor is charged by a fixed current plus

an additional current which is proportional to the voltage

applied to the PLLFLTR pin. Refer to Phase-Locked Loop

and Frequency Synchronization in the Applications Infor-

mation section for additional information.

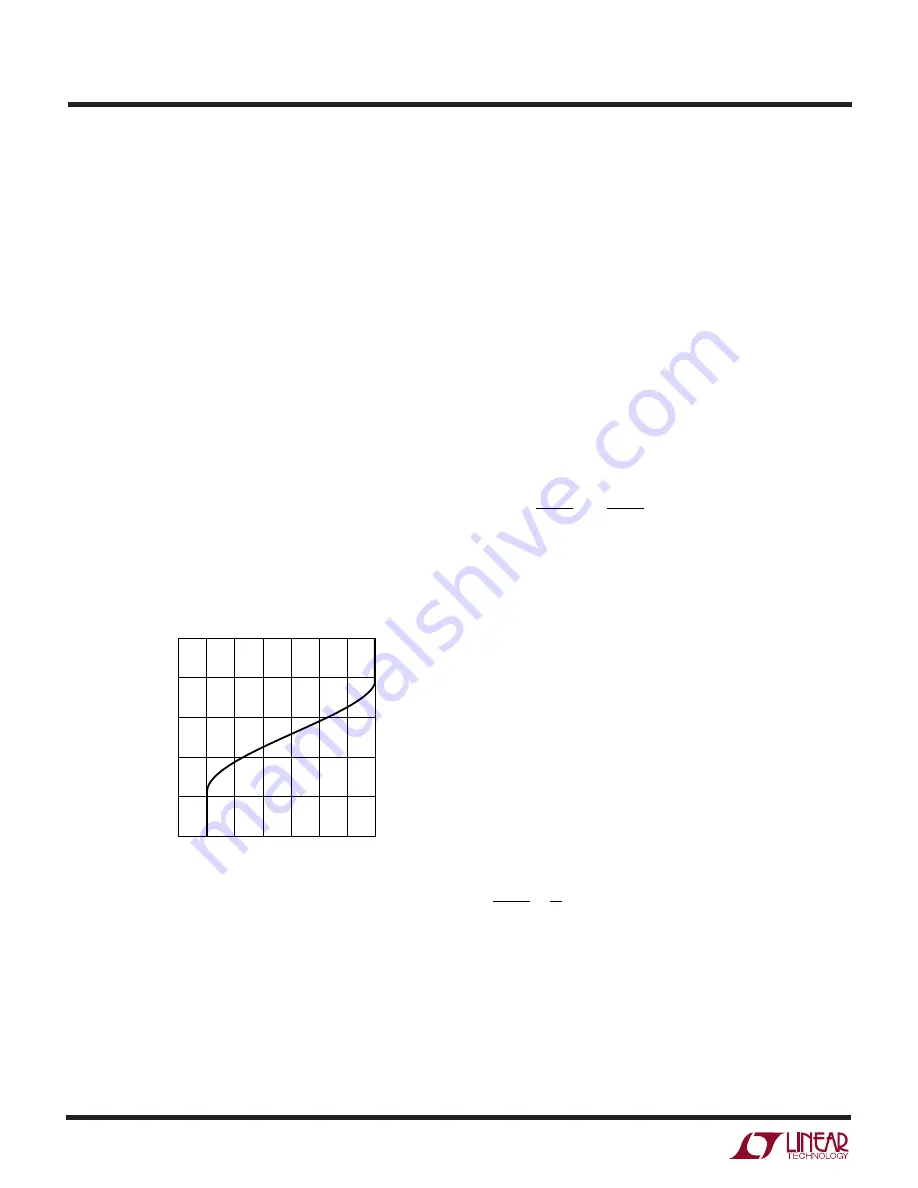

A graph for the voltage applied to the PLLFLTR pin vs

frequency is given in Figure␣ 2. As the operating frequency

is increased the gate charge losses will be higher, reducing

efficiency (see Efficiency Considerations). The maximum

switching frequency is approximately 550kHz.

anyone ever choose to operate at lower frequencies with

larger components? The answer is efficiency. A higher

frequency generally results in lower efficiency because of

MOSFET gate charge and transition losses. In addition to

this basic tradeoff, the effect of inductor value on ripple

current and low current operation must also be consid-

ered. The PolyPhase approach reduces both input and

output ripple currents while optimizing individual output

stages to run at a lower fundamental frequency, enhancing

efficiency.

The inductor value has a direct effect on ripple current. The

inductor ripple current

∆

I

L

per individual section, N,

decreases with higher inductance or frequency and in-

creases with higher V

IN

or V

OUT

:

∆

I

V

fL

V

V

L

OUT

OUT

IN

=

−

1

where f is the individual output stage operating frequency.

In a PolyPhase converter, the net ripple current seen by the

output capacitor is much smaller than the individual

inductor ripple currents due to the ripple cancellation. The

details on how to calculate the net output ripple current

can be found in Application Note 77.

Figure 3 shows the net ripple current seen by the output

capacitors for the different phase configurations. The

output ripple current is plotted for a fixed output voltage as

the duty factor is varied between 10% and 90% on the

x-axis. The output ripple current is normalized against the

inductor ripple current at zero duty factor. The graph can

be used in place of tedious calculations. As shown in

Figure␣ 3, the zero output ripple current is obtained when:

V

V

k

N

OUT

IN

=

where k = 1, 2, …, N – 1

So the number of phases used can be selected to minimize

the output ripple current and therefore the output ripple

voltage at the given input and output voltages. In applica-

tions having a highly varying input voltage, additional

phases will produce the best results.

Figure 2. Operating Frequency vs V

PLLFLTR

OPERATING FREQUENCY (kHz)

200

250

300

350

550

400

450

500

PLLFLTR PIN VOLTAGE (V)

3729 F02

2.5

2.0

1.5

1.0

0.5

0

Inductor Value Calculation and Output Ripple Current

The operating frequency and inductor selection are inter-

related in that higher operating frequencies allow the use

of smaller inductor and capacitor values. So why would