29

10. Cleaning

10.1 Basics

Cleaning should be carried out in accordance with the operator's

own company rules, and cleaning agents and devices and the

personal protective equipment to be used should likewise be

selected in accordance with those rules. Only cleaning agents

compatible with the materials may be used for cleaning.

Completely remove any cleaning agent residue left on the

product and rinse with clear water. Unauthorized persons must

be kept away. Use signage to indicate wet areas.

10.2 Interior cleaning

The interior normally does not need to be cleaned. The interior

of the product must be cleaned if incorrect or contaminated

lubricant accidentally enters the product. Please contact our

Service department.

10.3 Exterior cleaning

Do not allow any cleaning fluid to enter the interior of the

product during cleaning.

<

WARNING

Risk of fatal electric shock

Cleaning work may only be performed on

products that have been de-energized first. When

cleaning electrical components, be mindful of the

IP enclosure rating.

<

WARNIG

Serious injury from contact with or inhalation

of hazardous substances

Wear personal protective equipment. Observe the

safety data sheet (SDS) of the hazardous

substance. Avoid contaminating other objects or

the environment during cleaning.

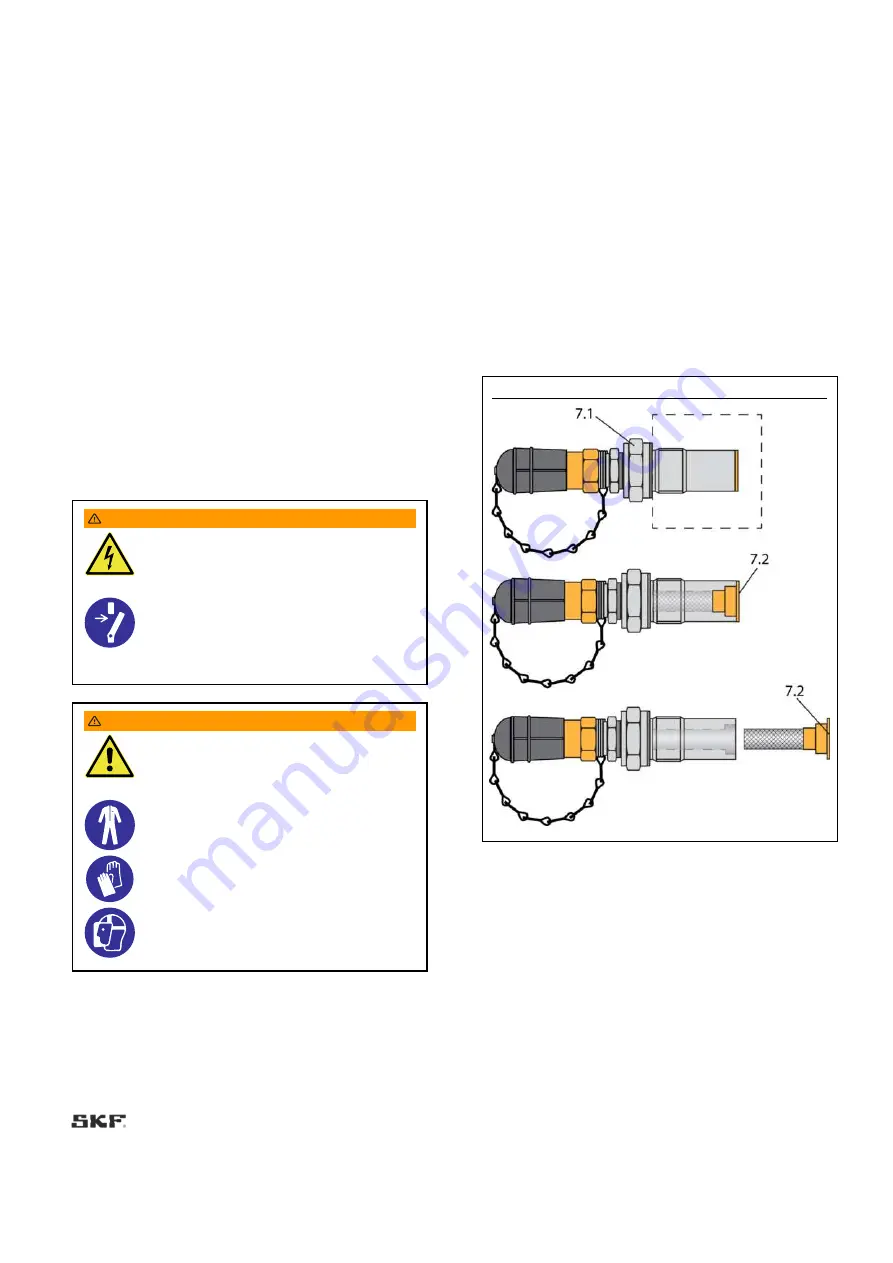

10.4 Cleaning the filter of the filling

connection

If the filter of filling connection 169-460-406 requires cleaning

due to contamination, proceed as follows:

1.

Loosen the filling connection at its hexagon (

7.1

) with a fork

wrench AF 27.

2.

Loosen the filter (

7.2

) at its hexagon socket (AF 6) and

remove it.

3.

Clean filter (

7.2

) with appropriate detergent and dry, e.g. with

compressed air.

4.

Mount all parts again in reverse order.

Tightening torques:

7.2 Filter (AF 6): 10 Nm ± 1.0 Nm

7.1 Filling connection (AF 27) 20 Nm ± 2.0 Nm

Fig. 21

Cleaning the filter of the filling connection