Subject

to

modifications

Page Number 17 of 28

2.1B-38008-A01

QLS 311

Form 403074

Installation and Operation Instructions

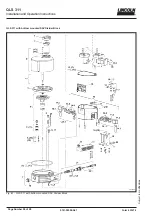

Fig. 32 - Example of a QLS 311

4232a99

Troubleshooting, Continuation

Divider Block of the QLS 311

Fault: Blockage in the downstream progressive system, pump doesnt run

Cause:

Bearings, lines or divider block clogged.

Mounting position of divider block : bottom

- On divider block SSV 8,12 and 18 the outlet ports 1 and/

or 2 are closed.

Mounting position of divider block: back-side,

- On divider block SSV 6, 12 and SSV 18 the outlet 1is

closed and out let 2 is connected for bearing lubrication.

The fault can be identified as follows:

a) Fault indication

Er

flashing on the key pad

display.

b) The indicator pin mounted on the divider block

piston does not move.

Remedy:

Determine the cause of the blockage as described in

the following example and eliminate it:

* Let the pump run (refer to Initiating an additional lube

cycle)

* Disconnect all feed lines of the divider block one after

the other. If oil shows under pressure (i. e. at outlet 3,

Fig. 32) the blockage is located in the line of outlet 3 or

in the connected bearing point.

* Pump through the blocked line or bearing point using a

hand pump.

Note: To check the individual outlets, leave all outlet

disconnected for a while, since only one piston stroke is

executed with each motor revolution. Several strokes are

required for a full cycle of all divider blocks.

* Check pressure relief valve (Fig.18). Replace it, if

necessary.

A - pressure relief valve

B - pump

C - SSV 12 divider block

D - feed lines

* Ceck the length of control pin while it moves over the

surface of the proximity switch (forward and backward

movement). During the insert status, the end of the

control pin should be located on the edge of the switch

surface. Otherwise, the pin has to be shortened by

approx. 1 mm (0.03 in).

Fault: Pump either does not switch off at all or only after the monitoring time of 15 min. (Continuation)

Cause:

Remedy:

Control pin is too long.