Subject to modifications

Page 7 of 16

User Manual

Operation Instructions

4.1EN-10004-A08

LINCOLN G

MB

H • P

OSTFACH

1263 • D-69183 W

ALLDORF

• T

EL

+49 (6227) 33-0 • F

AX

+49 (6227) 33-259

Installation, continuation

Connection of the Lubricant Supply

Connect the port on the bottom of reservoir 5 (Fig. 1) with

supply line B (Ø 12 mm) and with MOP inlet port 4.

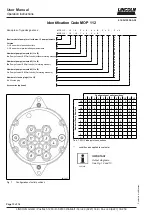

Use of Quicklinc Connecting Elements

6051b03

Fig. 2

Connection of Quicklinc connecting element and line

Connect

Push the line in the direction of arrow A (Fig. 2) into the

Quicklinc connecting element until it stops.

Disconnect

Press the line together with pliers B in the direction of

arrow A into the Quicklinc connecting element in order to

loosen the fastening clamps.

Hold pliers B tight and pull out the line in the opposite

direction to arrow A.

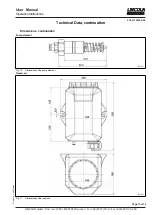

Pump Elements

6757b07

Fig. 3

Pump Element

Pump elements are available in 3 versions:

without/ with 1/ with 2 metering washers.

The MOP can be supplied with up to 12 preassembled

pump elements.

The output of a pump element depends on the number of

preassembled metering washers and the speed of the

driving shaft provided by the user.

Preassembled pump elements can be unscrewed for

replacement purposes.

Instead of a pump element, the MOP can also be

equipped with a closure plug at the intended port.

6001a02

IMPORTANT

To avoid the emptying of the full MOP,

interrupt the lubricant supply from the res-

ervoir and reduce the oil level in the MOP.

Make sure to check the lube points visually

in order to avoid unintended lubricant

penetration.

Connection of Lube Points

Connect respectively one lube point (brush, felt strip,

Fig.

6

) with a pump element of suitable output. Therefore

use feed line Ø 6 mm (Pos. C).

In any application, make sure that the oil quantity is dis-

tributed evenly over the whole width of the link chain

(Fig. 6 & 7 in Fig. 6).