Page 6 of 16

User Manual

Operation Instructions

Subject to modifications

4.1EN-10004-A08

LINCOLN GmbH • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Safety Instructions, continuation

Installation

1013A94

ATTENTION!

The use of any spare parts can result in

serious damage to your lubrication device.

Therefore, for the operation of your lubri-

cation device use only original spare

parts

1)

by Lincoln GmbH.

1)

See as of page 14 “Spare Parts and Accessories“

6001a02

IMPORTANT

Observe the installation guidelines and

instructions of the machine/ unit manufac-

turer when drilling and welding, as well as

the specified minimum distance on vehicle/

chassis frames for holes between up-

per/lower rim of the frame or between two

bores.

Installation and Maintenance of Lubricating Hoses

1013A94

ATTENTION!

The operational safety of the MOP (me-

chanically-driven oil pump) is only guaran-

teed with a professional installation and

maintenance of hydraulic hoses/lines.

Observe the following points!

Lubrication lines

may never be subjected to torsion

must be installed twist-free

must not rub against metal components or edges

are to undergo regular visual checks and must be ex-

changed in the case of wear.

Pay attention with non linear installations to allow for as large

a bending radius as possible. Avoid kinks! In constricted

installation conditions use pipe elbow unions to avoid the

danger of kinking behind the hose socket.

Installation

Location & Fixation

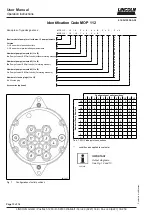

B-MOP112-010a08

Fig. 1

Installation of MOP and reservoir

Install the MOP 1 (Fig. 1) vertically and on smooth planes

(//D = max. 0.3 mm) directing the MOP driving shaft 3 to

the prolonged driving shaft A (provided by the user).

MOP driving shaft Ø .……………………………… 8 mm

MOP range of speeds:

- Shaft 1 / 2 ……………………………… 30 up to 280 min

-1

Fix the reservoir 5 of the MOP vertically. Make sure to

provide a proper line run B between MOP (on driving

shaft A) and reservoir 5.

Provide sufficient space for a later filling of the reservoir

from the top (min. 500 mm).

A fastening set consisting of 2 screws, 4 washers and

2 nuts (M8) is included in each MOP 112 supplied (tight-

ening torque 10 Nm ±5%).

1013A94

CAUTION!

Before starting any maintenance or repair

work, disconnect the MOP from the power

supply to avoid unintended operation.

1 -

MOP (mechanically-driven oil pump)

2 -

Pump element (1 of optional 12)

3 -

MOP driving shaft

4 -

MOP inlet port

5 -

Reservoir, 5 liters

A -

Driving shaft (to be provided by user)

B -

Lubricant supply line (Ø 12 mm)

C -

Lubricant feed line (Ø 6 mm)

//D - Admissible tolerance of smoothness (0.3 mm)