Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Section TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC

Retur

n to Master TOC

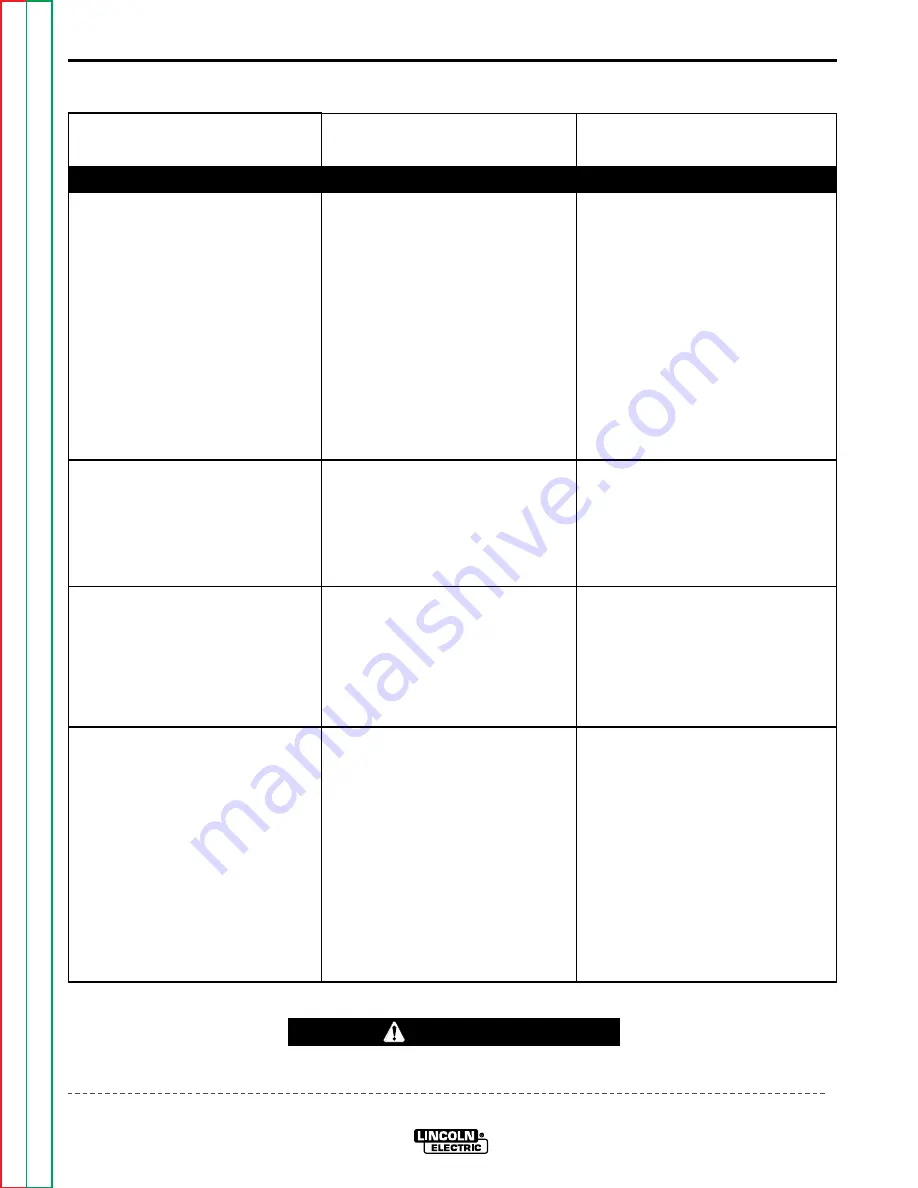

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

F-6

TROUBLESHOOTING AND REPAIR

F-6

Observe all Safety Guidelines detailed throughout this manual

FUNCTION PROBLEMS (Continued)

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric

Service Department for technical troubleshooting assistance before you proceed. Call 216-383-2531 or 1-800-833-9353.

CAUTION

LN-742 & LN-742H

The LN-742 voltmeter does not

function or read correctly when the

actual arc voltage is present. The

wire feeder is feeding wire correctly.

The LN-742 shuts down while weld-

ing and the HXX symbol appears on

the display.

The display and/or indicator lights

do not change when the arrow or

select keys are pressed.

The arrow keys do not change the

welding wire feed speed.

1. Make sure the polarity switch on

the Lincoln welding power

source is in the correct position

for the welding process.

2. Check or replace the control

cable. Check the continuity

(zero ohms) of leads #21 and

#67.

1. Check for mechanical restric-

tions in the wire feed path.

1. Make sure the control cable is

connected to the welding power

source correctly.

2. Check the 42 VAC fuse or circuit

breaker in the welding power

source.

1. If a remote control unit is con-

nected to the LN-742 the arrow

keys will not change welding wire

feed speed. Use the WFS pot on

the remote control unit or discon-

nect the remote control unit and

use the arrow keys.

1. Check the DC voltage at plug J1

pin 6 (lead #67) to pin 11

(lead #21) when arc voltage is

present at the power source out-

put terminals. Arc voltage should

be present at these leads. If not,

check the leads between the

input cable receptacle and plug

J1. Plug J1 is located on the con-

trol board. See wiring diagram.

2. If arc voltage is present at plug J1

the control board may be faulty.

Replace.

1. Perform the

Drive Motor Test.

2. The gear box may be defective.

Check or replace.

3. The control board may be faulty.

1. Perform the

Keypad Resistance

Test.

2. The display board may be faulty.

3. The control board may be faulty.

1. The display board may be faulty.