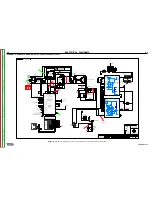

ELEcTricaL DiaGramS

G-11

vaNTaGE® 500

SchEmaTic - cOmpLETE machiNE - G4848 (cODES 11180, 11415 & 11468 DEuTz) paGE 2

G4848

VANTAGE 500 DEUTZ

MACHINE SCHEMATIC

NONE

G4487

B. MUTER

N.S.

DO NOT SCALE THIS DRAWING

DRAWN BY:

DESIGN INFORMATION

ENGINEER:

APPROVED:

EQUIPMENT TYPE:

SUBJECT:

SCALE:

UF

CRM36466

2

PAGE ___ OF ___

2

ENGINEERING CONTROLLED

MANUFACTURER:

No

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

A

08/03/2004

t

MATERIAL TOLERANCE (" ") TO AGREE

WITH PUBLISHED STANDARDS.

ON ALL ANGLES IS ± .5 OF A DEGREE

ON 3 PLACE DECIMALS IS ± .002

ON 2 PLACE DECIMALS IS ± .02

UNLESS OTHERWISE SPECIFIED TOLERANCE:

MANUFACTURING TOLERANCE PER E2056

Released A.01 from X

CHANGE DETAIL:

REFERENCE:

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

G48

48

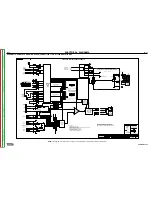

SIMPLIFIEDCONTROL BOARDSCHEMATIC

J7-1

J7-4

J7-5

+10V

+10V

J1-10

J1-14

J1-11

TIG MODE

ALL OTHER MODES

ARC

CONTROL

CIRCUITRY

CONTROL

POINT

SELECT

VARIABLE PINCH

PIPE ARC FORCE

VARIABLE ARC FORCE

FIXED ARC FORCE

LOCAL

REMOTE

TOUCH START

OCV

J7-6

J7-7

J7-8

x80

G4109

(ONLY)

G4107

(ONLY)

47.5 ohms

J3-15

J6-2

J6-1

VOLTAGE FEEDBACK

CURRENT FEEDBACK

J5-10

J5-9

J5-8

J5-7

J5-6

J5-5

J5-4

J5-3

J5-2

J5-1

J4-10

J4-9

J4-8

J4-7

J4-6

J4-5

J4-4

J4-3

J4-2

J4-1

MACHINE/

MODE

LOGIC

(CPU)

HOLD (+5V=HOLD)

ON / OFF (+5V=ON)

ON / OFF (+5V=ON)

HOLD(+5V=HOLD)

J7-16

J7-9

J7-10

J7-11

J7-12

J7-13

J7-14

J7-15

TIG MODE

PIPE MODE

(NOT AVAILABLE ON AUSTRALIAN

VANTAGE 575)

N/A

N/A

N/A

ROCV ENABLE

(FOR AUSTRALIAN VANTAGE 575)

CV MODE

+15V

J1-5

J1-6

J1-7

J1-8

J1-13

+15V

J1-12

MACH SEL 4

MACH SEL 3

MACH SEL 2

MACH SEL 1

PRESET

CURRENT FEEDBACK

VOLTAGE

FEEDBACK

AMMETER

DISPLAY

VOLTMETER

DISPLAY

SELECT CONTROL POINT

FIXED HOT START

J3-14

IDLE SWITCH SENSE

+15V

J3-7

J1-3

J1-4

+15V

(4)

(2)

2-4 SENSE

J3-4

J3-3

REGULATING

AMPLIFIER

PWM

CHOPPER

CONTROL

CIRCUIT

CURRENT

LIMITS,

AVERAGE,

ABSOLUTE,

& FOLDBACK

TH

E

R

M

A

L

S

H

U

TD

O

W

N

THERMAL SHUTDOWN (if used)

CURRENTFEEDBACK

CONTROL POINT

J3-12

J3-10

J3-11

J3-9

47.5 ohm

TRANSFORMER

+15V

+3.3V

-15V

+5V

J3-16

J3-8

-

+

40-100VDC

INPUT

FRAME

+15V

IDLE CONTROL

IDLE CONTROL

+15V COM

FRAME

J2-6

J2-4

J2-5

IDLE HOLD COIL

TO IDLE PULL COIL BOARD

HIGH = PULL TO LOW IDLE

FRAME

+15V COM

+12VISOLATEDCIRCUITRYFORENGINEFUNCTIONS

- STUD

+STUD

AUXILLARY

CURRENT

SENSE

-

+

10K

POT

10K

POT

10K

POT

AUXILIARY

SENSE

TOROID

MACHINE IDENTITY TABLE:

PINS JUMPERED TO SELECT MACHINE

1

2

3

4

A

TIG

PIPE

CC

CV

MODE

SELECTOR

SWITCH

(AUSTRAILIAN

VANTAGE 575 USES A

3 POSITION TOGGLE

SWITCH)

(77)

(76)

(75)

(77B)

(76B)

(75B)

(277)

(278)

(279)

OUTPUT

CONTROL

REMOTE

CONTROL

ARCCONTROL

+ STUD

(206S)

(204S)

+

-

(208B)

METER (+) INPUT (0 - 2V) 1V = 100.0 ON METER

1

2

3

4

HOLD

COIL

PULL

COIL

IDLE

SOLENOID

BLK

RED

WHT

PULL COIL

BOARD

J1-5

J1-6

J1-7

J1-8

MACHINE

RANGER 250 G&D

J1-13

RANGER 305 G&D

J1-13

VANTAGE 500

J1-13

VANTAGE 575

J1-13

AIR VANTAGE 500

#1

CHOPPER

BOARD

#2

CHOPPER

BOARD

47.5 ohm

47.5 ohm

47.5 ohm

(ALL MACHINES)

(VANTAGE ONLY)

50mV = 400 AMPS

SHUNT

+

-

CONTROL BOARD

POWERFROM

CHOPPERBOARD

FEEDBACK

CURRENT LIMITS

REGULATION MODE

METER (-) INPUT

METER (+) INPUT (0 - 2V) 1V = 1000 ON METER

METER (-) INPUT

BLINK (PULLED LOW AND HIGH

IN LOOKBACK TO FLASH

DECIMAL POINT)

BLINK (PULLED LOW AND HIGH

IN LOOKBACK TO FLASH

DECIMAL POINT)

+12V Battery Supply

PWM SIGNAL (+12V ON MULTIMETER)

PWM COMMON

PWM SIGNAL (+12V)

PWM COMMON

+ STUD is COMMON

FOR WELD CONTROL

CIRCUITS

CONNECTORS

J1 AMPHENOL &MACHINEIDJUMPER

J2 ENGINE12VCONTROL FUNCTIONS

J3 CHOPPERPWM, POWERIN, (THERMAL OVERLOADIFUSED), VOLTAGEFEEDBACK

J4 AMMETER (NOCONNECTORONRANGER250)

J5 VOLTMETER (NOCONNECTORONRANGER250)

J6 SHUNT/CURRENTFEEDBACK

J7 OUTPUTCONTROL, ARCFORCE, MODESELECT

FRAME IS COMMON FOR

ENGINE CONTROL CIRCUITS

PRESET

PRESET

DISPLAY WELD AMPS

DISPLAY WELD VOLTS

DISPLAY

PRESET

VALUE

+5V

+5V

+5V

DIODE ONLY ON -E

VERSION AND ABOVE

THE TOP END OF THE REMOTE POT IN

TIG MODE IS THE SETTING OF THE LOCAL

OUTPUT CONTROL POT.

IN EVERY OTHER MODE, THE REMOTE

POT WILL SET MACHINE TO MAX OUTPUT.

METERSOPTIONAL ONVANTAGE

NOJ4 ORJ5 ONRANGER250

SEESPECIFICMACHINESCHEMATICFORDETAILSON

WHAT PARTSOFTHEG4107/G4109 AREUSED INEACH

APPLICATION. NOTALL CIRCUITSAREUSEDALL THETIME.

+15V

J7-2

WELDING

TERMINAL

CONTROL

SWITCH

SHOWN IN "ALWAYS

ON" POSITION

IDLER

CONTROL

SHOWN IN "HIGH" POSITION

J2-3

FRAME

+12 Volt

0 Volts

Pull Coil

Energized

0 Volts

Hold Coil

Energized

(ALL CIRCUITS ON CONNECTOR J2)

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

+ STUD

LEAD COLOR CODE:

B-BLACK

G-GREEN

O-ORANGE

R-RED

U-BLUE

W-WHITE

Y-YELLOW

COMPONENT VALUE UNITS:

CAPACITOR: MFD/VOLTS

RESISTOR: OHMS/WATTS

CONNECTOR PIN NUMBERS:

VIEWOF CONNECTORONPCBOARD

1 2

6

7

12

LATCH

EX. 12 PINCONNECTOR

LABELS:

COMMON

FRAME GROUND

EARTH GROUND

G-11

NOTE:

This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return

to

Section

T

OC

Return

to

Section

T

OC

Return

to

Section

T

OC

Return

to

Section

T

OC

Return

to

Master

T

OC

Return

to

Master

T

OC

Return

to

Master

T

OC

Return

to

Master

T

OC