English

English

41

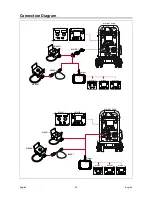

The 2-Step - 4-Step

changes the function of the gun’s

trigger.

•

2 Step trigger operation turns welding on and off in

direct response to the trigger. Welding process is

performed when the gun’s trigger is pulled.

•

4-Step mode allows to continue welding, when the

gun’s trigger is released. To stop welding, the gun’s

trigger is pulled again. 4-step mode facilitates to

making long welds.

Note:

4-Step does not work during Spot Welding.

A

Figure 85

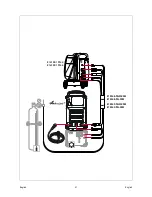

HOT START

– value in percentage of nominal value

welding current during arc start current. The control is

used to set the level of the increased current and arc

start current is made easy.

••••

Adjust range: from 0 to +10.

A

OFF

10.0

OFF

A

Figure 86

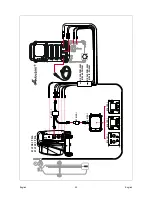

TailOut

provides additional heat into the weld without

increasing the arc length or the droplet size. Higher

tailout values improve wetting and may give faster travel

speeds.

••••

Adjust Range: from 0 to +10.

A

OFF

10.0

OFF

Figure 87

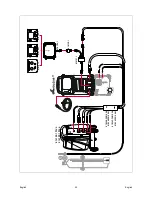

Background Current

adjusts the overall heat input into

the weld. Changing the background current changes the

shape of the back bead. 100% CO

2

requires less

background current than when welding with blended

shielding gases.

Note:

Range depends on the power source.

A

10

190

10A

Figure 88

Peak Current

controls the arc length, which also affects

the shape of the root. When using 100% CO

2

, the peak

current will be higher than when welding with blended

shielded gases. A longer arc length is required with CO

2

to reduce spatter.

Note:

Range depends on the power source..

A

14

546

14A

Figure 89