Section 1 - Description

The REDI-MIG 4D Wire Feeder has a drive plate with four

drive rolls (all driven). It has been designed for use with

continuous electrodes with or without an externally applied

shielding gas. The welding gun must have a standard

“Euro” connector at the machine end. Input power

requirements are 42V AC 50Hz, which is supplied by the

REDI-MIG Remote power source. The units also feature

electrical contacts to allow the power source output to be

switched on and off, so that the gun and electrode will be

electrically “cold” when not in use. A gas solenoid is

provided to automatically control gas flow when shielding

gas is used.

Front panel controls are:

(a) Electrode wire feed speed control

(b) Spot weld time switch and control

(c) “2 Step/4 Step” trigger mode switch for gun trigger

(d) “Gas Purge”/”Wire Inch” toggle switch

(e) A burnback control is situated in the wire bay area

Section 2 - Rating

Wire feeder rating is 400 amps max. at 60% duty cycle or

300 amps max. at 100% duty cycle. The current and duty

cycle must also be within the rated capacity of the power

source.

The wire feeder may be used with 0.6mm to 1.2mm dia.

solid wire, 1.0mm to 1.6mm aluminium wire and up to

1.6mm flux cored electrodes on standard spools (with a

50mm I.D. boss, 300mm max. O.D. and 15kg max.

capacity). Wire feed speed range is approximately 1 to 20

metres/min. (40 to 790 inch/mind.)

Weight is approximately 27kg.

Section 3 - Connections

The wire feeder is connected electrically to the power

source by two cables.

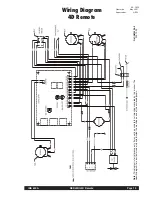

1. The control/power cable includes a 4-pin amphenol plug

and carries the following circuits:

a) 42V, 50Hz AC control power (isolated from chassis)

b) A closing contact to switch on the welders output

(provides 42V switched on pins ‘a’ and ‘b’)

c) 42V, 50Hz AC control power (isolated from chassis)

d) Earth. Chassis of power source to chassis of wire

feeder

2. The welding power cable from the power source’s

“electrode”* output.

*

Electrode polarity is determined by the wire and

welding process. Refer to the appropriate handbook

or the electrode packaging.

For gas shielded processes, connect the gas hose

(included with standard input cable assembly) to the gas

bottle regulator. Incoming gas pressure must not exceed

1000kPa and a gas regulator must be used.

Connect a suitable welding gun and cable assembly to the

“Euro” connector on the front panel. The REDI-MIG Remote

power sources are supplied with REDI-MIG guns as

follows:

Machine

Torch

REDI-MIG 255 Remote

REDI-MIG 240

REDI-MIG 325 Remote

REDI-MIG 360

Section 4 - 42V AC 50Hz Supply

If the welding power source to be used does not have a 42V

AC auxiliary supply, a step-down transformer will be

required. This transformer must have a minimum rating of

220VA and an output voltage of 42V + 5% 50Hz AC.

Contact Lincoln for further details required.

Section 5 - Control Panel

5.1 Wire Feeder Speed Control

Use this control to adjust the speed at which the electrode

wire feeds when welding. This is in effect a current control

as the power source will deliver the current necessary to

melt the wire. The higher the speed, the more current will

be required. Wire feed speed range is approximately 1 to 20

metres/min. (40 to 790 inch min.)

Operation of the gun trigger, switches the wire feed motor

on and off, depending upon the trigger mode setting. The

wire feed motor is dynamically braked to minimise wire

overrun after welding has ceased.

Welding voltage is available immediately the gun trigger is

operated. When welding is stopped there is a delay to allow

the electrode to burn back slightly and prevent sticking in

the crater.

5.2 2 Step/4 Step Operation

A two position toggle switch on the front panel provides two

modes of operation of the gun trigger. In 2 Step mode, the

gun trigger is pressed to start welding and released to stop.

In 4 Step mode, pressing the gun trigger only operates the

gas solenoid, allowing shielding gas to flow. Releasing the

trigger activates the contactor which starts the wire feed

motor and connects welding current to the wire so that

welding may commence. To stop welding, the trigger must

again be operated; pressing it stops the wire feed, activates

the burn back time delay and opens the contactor after the

pre-set burn back time. Releasing the trigger stops the gas

flow.

To recommence welding, the above cycle must be

repeated.

5.3 Spot Welding

In spot welding mode, welding takes place for a pre-set

time and then stops automatically. Welding time is

adjustable between approx. 0.5 sec and 4 sec by operation

of the spot weld control on the front panel. There is a

positive click in the extreme anticlockwise position to

indicate that the spot weld feature is “off”.

5.4 Gas Purge / Wire Inch

Use the gas purge momentary toggle switch to operate the

gas solenoid to purge air from the hose after connecting a

new gas cylinder. Gas purge will only operate while the

toggle switch is held upwards.

Use this same toggle switch to operate the wire feed motor

and “cold” inch the wire without operating the power source

contactor or gas solenoid, by pushing the toggle switch

downwards.

5.5 Burnback Control

This control is located in the wire feed bay. The burnback

control adjusts the time period from when the drive motor

stops until the power source and gas solenoid are switched

off. [Approx 0.1 seconds (when fully counterclockwise) to

approx 1.1 seconds (when fully clockwise)].

The purpose of the burnback control is to prevent the

electrode wire sticking in the weld crater at the finish of the

weld.

Page 8

REDI-MIG 4D

IMA 600A

CONNECTION & OPERATION

ELECTRIC SHOCK can kill

ARC RAYS can burn

Содержание KA 1435

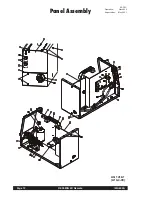

Страница 14: ...Page 14 REDI MIG 4D Remote IMA 600A NOTES...

Страница 18: ...Page 18 REDI MIG 4D Remote IMA 600A Wire Drive Assembly AP 56 E Operative Apr 2004 Supersedes NEW Ref 410...

Страница 20: ...Page 20 REDI MIG 4D Remote IMA 600A Wire Drive Assembly AP 56 F Operative Apr 2004 Supersedes NEW Ref 410 2...

Страница 22: ...Page 22 REDI MIG 4D Remote IMA 600A NOTES...

Страница 23: ...IMA 600 REDI MIG 4D Remote Page 23 NOTES...