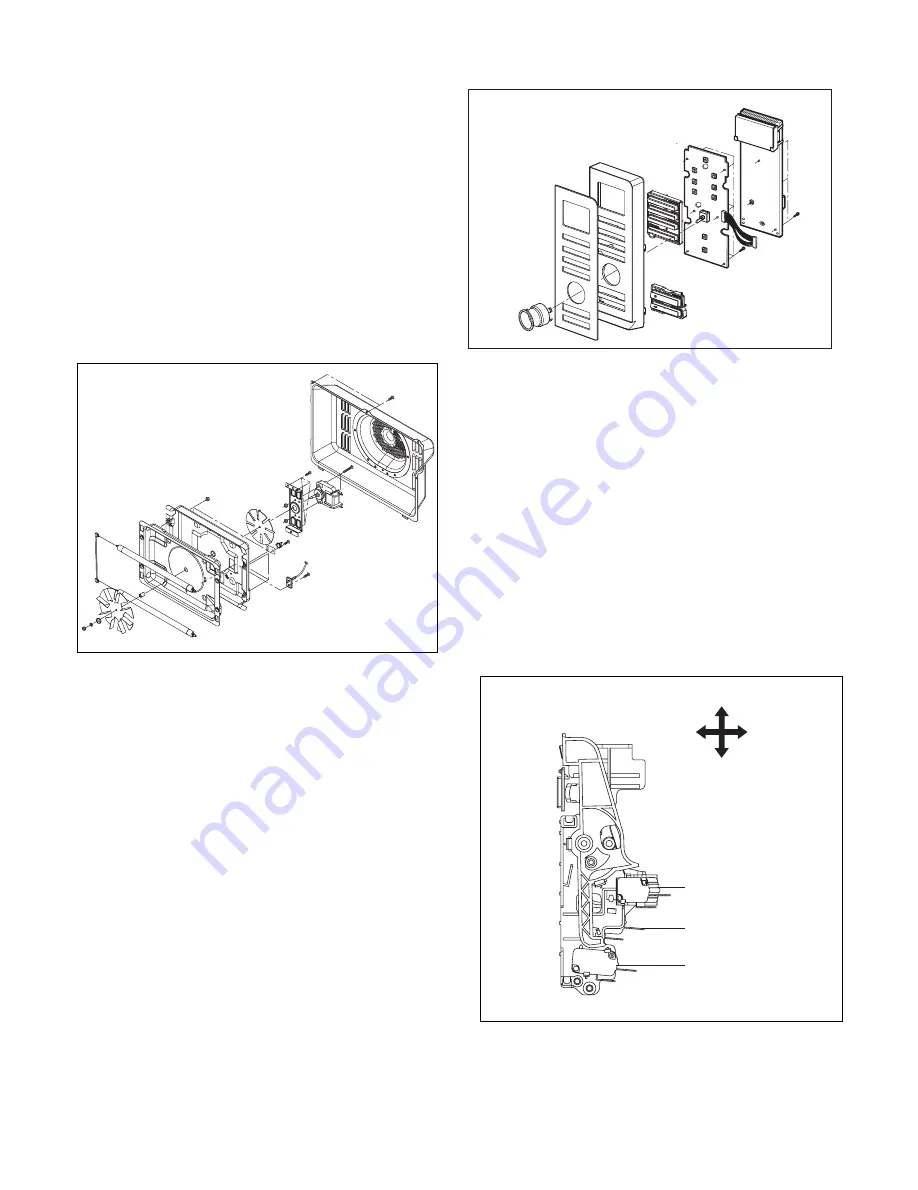

K. C-MOTOR, THERMISTOR AND

SHEATH HEATER REMOVAL

1) Remove the two screws securing the cover

assembly to the oven cavity.

2) Disconnect the leadwire from the circulation motor

terminal and the sheath heater.

3) Remove the screws of the thermistor, guide assy-

chamber and lift up the guide assy-chamber.

4) Remove a hex nut securing the circulation fan to

shaft of the C-motor.

5) Remove screws securing the motor bracket to the

guide assy-chamber.

6) Remove two hex nuts securing the C-motor to the

motor bracket.

L. PCB ASSEMBLY REMOVAL

1) Remove the control panel assembly from the

cavity. (Refer to control panel assembly removal

on previous page.)

2) Remove screws which hold the PCB SUB ASS’Y to

the control panel.

3) Disconnect the flat cable from the PCB SUB

ASS’Y and take off the PCB SUB ASS’Y.

M. INTERLOCK SYSTEM

1) INTERLOCK MECHANISM

The door lock mechanism is a device which has

been specially designed to eliminate microwave

activity when the door is opened during cooking

and thus to prevent the danger resulting from the

microwave leakage.

2) MOUNTING OF THE PRIMARY/MONITOR/

SECONDARY SWITCHES TO THE LATCH BOARD

3) INSTALLATION AND ADJUSTMENT OF THE

LATCH BOARD TO THE OVEN ASSEMBLY

• Mount the latch board to the oven assembly.

• Adjust the latch board in the arrow direction so that

oven door will not have any play in it when the door

is closed.

• Tighten the mounting screw.

5-6

PRIMARY

SWITCH

SECONDARY

SWITCH

ADJUSTMENT

DIRECTION

MONITOR

SWITCH

LGE Internal Use Only

Copyright © 2009 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Содержание MC3283FMPG

Страница 40: ... 6 2 DOOR PARTS EV 13581A ...

Страница 41: ... 6 3 CONTROL PANEL PARTS EV 23572A 23806C 268712 268711 250204 250203 249401 23550C 24930M SUB MAIN ...

Страница 43: ... 6 5 43500B LATCH BOARD PARTS EV 568771 466003 466003 466001 14510L ...

Страница 45: ... 6 7 BASE PLATE PARTS EV 56170D 64970A ...

Страница 46: ......