—23—

RE-

MARKS

LOCATION

NO.

PART NO.

DHA1260HL

DHA1260HR

DESCRIPTION

Q'TY

PERSET

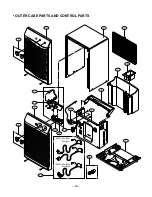

OUTER CASE PARTS

CONTROL PARTS

S: SERVICE PARTS A: ALTERNATE PARTS N: NOT SERVICE PARTS

6. REPLACEMENT PARTS LIST

• MODEL: DHA1260HL/HR

3041AD2007E

BASE ASSEMBLY WELD [SINGLE]

1

R

3090A10001E

3090A10001E

CABINET

1

R

3531A20012C

3531A20014D

GRILLE ASSEMBLY, FRONT

1

R

4790AD2003B

BARRIER, SINGLE

1

R

4838A10001A

4838A10001A

TANK, BUCKET

1

R

4941A30002A

4941A30008A

KNOB ASSEMBLY

2

R

5230AD3005A

5230AD3005A

FILTER MECH, AIR

1

R

3086AD2014C

3086AD2014F

DRAIN PAN

1

R

4768A30001A

4768A30001A

FLOAT

1

R

3H00390A

TERMINAL, BLOCK

1

R

3720AD3004A

PANEL, CONTROL

1

R

6411A20001B

6411A20001B

POWER CORD ASSEMBLY

1

R

6600A20001A

SWITCH, ROTARY

1

R

5216A20001A

HUMIDISTAT

1

R

6600A30003B

SWITCH ASSEMBLY, MICRO

1

R

2H01127F

THERMOSTAT ASSY

1

R

6912A30001B

LAMP, NEON

1

R

6421A90001C

SOLENOID COIL

1

R

4998AD2002A

SHROUD

1

R

4681A20002D

MOTOR ASSEMBLY, SINGLE

1

R

4960AD3003A

MOUNT, MOTOR

1

R

5211A30195A

TUBE ASSEMBLY, SUCTION

1

R

5211A30194A

TUBE ASSEMBLY, DISCHARGE

1

R

5421A20004D

EVAPORATOR ASSEMBLY

1

R

3550C-0021A

COVER, P.T.C.

1

R

4H00972G

WASHER, PLAIN

4

R

5040AR4195A

ISOLATOR, COMP.

4

R

5211A30008D

TUBE ASSEMBLY, CAPILLARY

1

R

5403A20001C

CONDENSER ASSEMBLY

1

R

5416A20009A

COMPRESSOR, RECIPRO

1

R

5851A30001A

DRIER ASSEMBLY

1

R

5900AD2013A

FAN ASSEMBLY, PROPELLER

1

R

6748C-0003C

P.T.C. ASSEMBLY

1

R

6750C-0005M

O.L.P.

1

R

1NHA0801206

NUT, HEXAGON (1)

4

R

4H02861A

FAN NUT

1

R

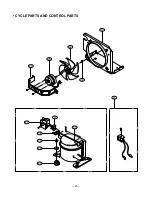

CYCLE PARTS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Содержание DHA1260HL

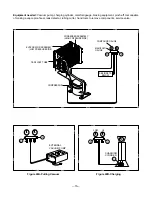

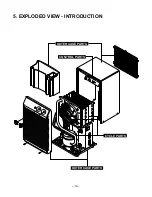

Страница 19: ...5 EXPLODED VIEW INTRODUCTION 19 OUTER CASE PARTS OUTER CASE PARTS CONTROL PARTS CYCLE PARTS ...

Страница 21: ... CYCLE PARTS AND CONTROL PARTS 21 21 20 32 36 19 30 33 18 35 34 25 26 27 ...

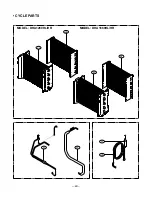

Страница 22: ... CYCLE PARTS 22 22 23 29 24 29 24 28 31 MODEL DHA1660HL HR MODEL DHA1260HL HR ...

Страница 25: ...P No 3828A30001W Printed in China ...