Diagnostic Information 2-17

Print Quality - Residual Image

Install a new print unit if one is available, before you begin this check.

Residual image can be caused by the photoconductor, cleaning

mechanism, and other parts inside the print unit.

Print Quality - Banding

Banding appears as light or dark horizontal lines on a uniformly gray

page, or on a page with a large area of graphics. Banding is prima-

rily due to a variation in the speed of the paper as it feeds through

the printer, especially in the developer and transfer process. Inspect

the paper feed components, especially the drive gears, for signs of

wear, dirt, binds, or damage.

Print Quality - Background

Some background problems can be caused by an incorrect paper

setting. Be sure the correct paper type setting is selected for the

paper being used. Background can also be caused by an incorrect

setting on the print darkness control. The customer may try to

improve the print quality by adjusting the print darkness dial.

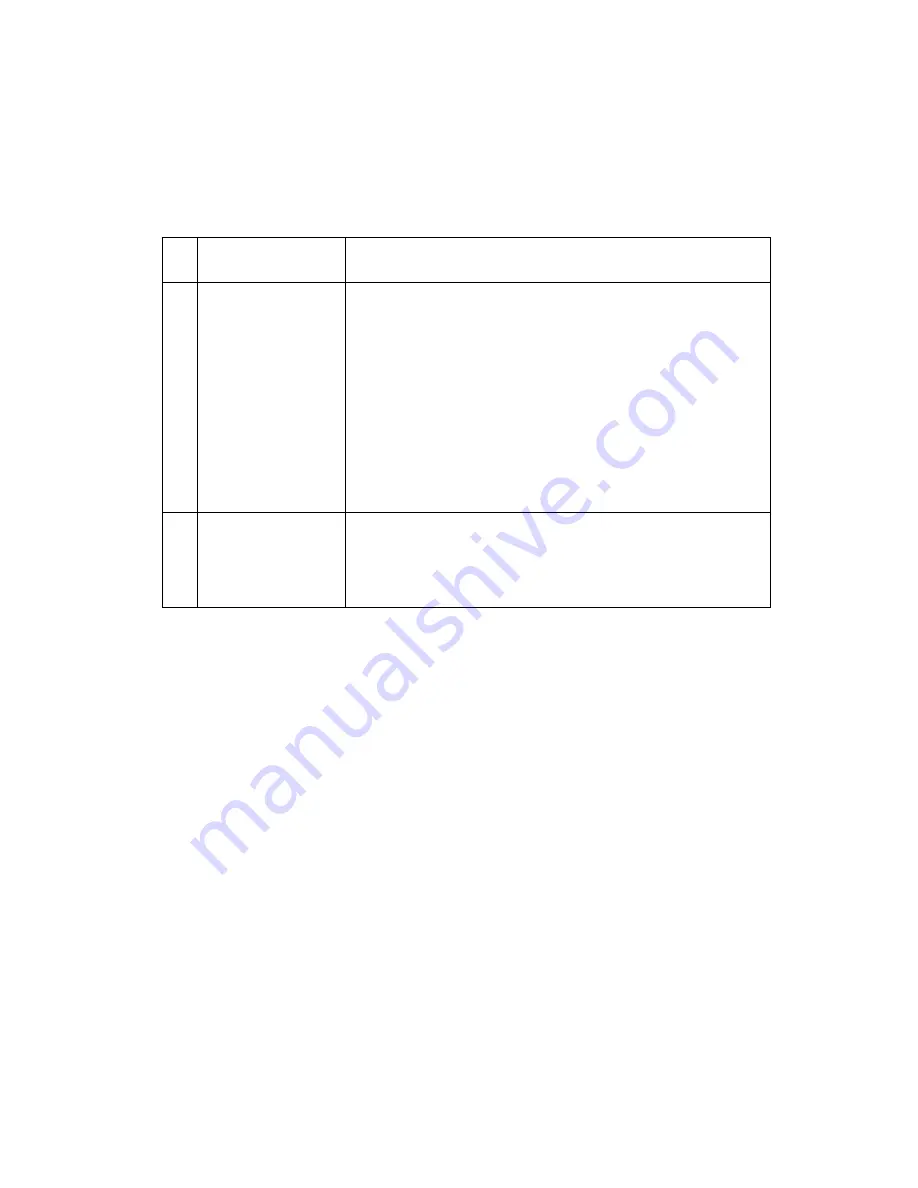

FRU

Action

1

Erase LED

Assembly

Check the erase LED for signs of paper dust, toner

build-up or other contamination. Clean with a soft

cloth or replace the erase LED assembly. When the

erase LEDs work properly, each LED turns bright

red. This is visible with the print unit removed, by

opening the upper door during the warming engine

step in the POST procedure. If the erase LEDs do

not come on, check the voltage at CNERS-1 on the

engine board. It should m24 V dc. If it is

incorrect, replace the engine board. If it is correct,

replace the erase LED assembly.

2

Fuser

Check the fuser for signs of toner buildup on the hot

roll. Toner buildup could cause the hot roll to pick up

toner and deposit it down the page. If buildup is

present, replace the fuser.

Содержание Optra K 4046

Страница 15: ...Notices and Safety Information xv Chinese Laser Notice Korean Laser Notice ...

Страница 19: ...Notices and Safety Information xix ...

Страница 20: ...xx Service Manual ...

Страница 26: ...1 6 is transmitted to the paper feed roller ...

Страница 29: ...General Information 1 9 to the upper exit bin Roller gears receive power from the hot roll gear ...

Страница 30: ...1 10 ...

Страница 60: ...2 30 ...

Страница 91: ...Repair Information 4 15 7 Remove four screws and disconnect the cable to remove the main motor ...

Страница 97: ...Repair Information 4 21 ...

Страница 105: ...Repair Information 4 29 Installation Note Install the fan so the air flow arrow is to the outside ...

Страница 109: ...Locations 5 1 5 Locations Front and Right Side of Printer ...

Страница 110: ...5 2 Rear and Left Side of Printer ...

Страница 111: ...Locations 5 3 Interior of Printer with Upper Door Open ...

Страница 112: ...Locations 5 4 Optional Multi Function Feeder and Paper Feeder ...

Страница 113: ...Locations 5 5 Sensors ...

Страница 114: ...5 6 EP Diagram ...

Страница 115: ...Locations 5 7 Engine Board ...

Страница 116: ...Locations 5 8 Control Board ...

Страница 117: ...Locations 5 9 Power Supply Board ...

Страница 118: ...5 10 Interconnect Board ...

Страница 120: ...6 2 Assembly 1 Upper Cover ...

Страница 122: ...6 4 Assembly 2 Covers ...

Страница 124: ...6 6 Assembly 3 Electronics ...

Страница 126: ...6 8 Assembly 3 Electronics cont ...

Страница 128: ...6 10 Assembly 4 Frame Left Side ...

Страница 130: ...6 12 Assembly 5 Frame Right Side ...

Страница 132: ...6 14 Assembly 6 Input Paper Feed ...

Страница 134: ...6 16 Assembly 7 Printhead and Paper Feed Redrive ...

Страница 136: ...6 18 Assembly 8 Exit Paper Feed Frame ...

Страница 138: ...6 20 Assembly 9 Fuser ...

Страница 140: ...6 22 Assembly 10 Paper Tray 250 Sheet ...

Страница 142: ...6 24 Assembly 11 Optional 450 Sheet Second Paper Tray ...

Страница 144: ...6 26 Assembly 12 Optional 450 Sheet Second Paper Drawer 2 ...

Страница 146: ...6 28 Assembly 13 Optional 450 Sheet Second Paper Drawer 2 ...

Страница 148: ...6 30 Assembly 14 Optional Multi Function Feeder ...

Страница 149: ...Parts Catalog 6 31 Ref Part Number Units Description 14 1 12A4024 1 Feeder Multi Function ...

Страница 152: ...6 34 ...