5

Commissioning

DYNEO

®

Synchronous motors with permanent magnets-drive

4474 en - 2011.04 / e

LEROY-SOMER

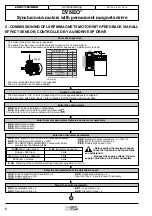

Measurement of the phase angle for the encoder or Hall effect sensor (

00.17

).

• Check that the motor is stopped and has been uncoupled from the load, then continue with autotuning.

• If a brake is present, check that it has been released (reactivate the brake after autotuning).

• Regardless of the required reference and direction of rotation, the autotuning procedure causes the motor

to run at very low speed.

Check that there is no danger to people and equipment.

• Once the procedure is complete, the motor stops automatically.

• The procedure can be interrupted at any time by sending a stop command, pressing the "STOP" button on

the parameter-setting interface (see STOP section 2.2.6 of manual ref. 3871) or opening the disable circuit.

•

00.42

: With rotation.

• Enable the drive (link terminals SDI1 - SDI2).

• Give a run forward command or run reverse command (in factory settings, close DI4 or DI5).

• The motor starts to turn. Wait until it stops completely and check that

00.42

= NO (autotuning complete).

• Remove the run command, disable the drive and check any changes in the value of

00.17

,

05.17

,

05.24

.

• In read mode, on the parameter-setting interface, the operating status displays “DISABLED” or “Encoder break”.

Switch on the drive

• Open the contact SDI1,SDI2.

• In parameter-setting mode, select basic parameters

•

00.45

Return to factory settings 50 Hz or 60 Hz, HIGH or LOW depending on the supply and the application

(

00.45

automatically returns to NO after a few seconds)

•

00.13

: SERVO. The drive displays “Encoder break”, continue with the procedure.

Select the control mode

•

00.06

: Motor rated current

•

00.07

: Motor rated speed

•

00.08

: Motor rated voltage

•

00.10

: Motor rated frequency

Enter the motor parameters indicated on the motor nameplate

•

00.14

: Type = HALL EFFECT or incremental UVW (depending of the sensor used)

•

00.15

: Drive encoder lines per revolution (not applicable to Hall Effect sensor)

• Clear the “Encoder break” trip with a RESET if necessary

Enter the characteristics of the incremental encoder with commutation channels or those of the Hall effect sensor

Enter the other motor and control parameters

• Enter the encoder phase angle (

α

)

manually in

00.17

,

located on the motor nameplate.

Possible to uncouple the motor?

YES

NO

Autotuning with rotation

• Couple the load

• Enable the drive (link terminals SDI1 - SDI2).

• Start the machine with no load and then on load, if necessary re-adjust the ramps (

00.03

,

00.04

) then the speed controller

gains via

00.18

(increase the factory settings in proportion with the inertia applied to the motor shaft),

00.19

and

00.16

.

Optimising performance

No autotuning

The drive is ready to operate, or waiting for additional parameter settings.

• If the drive trips, apart from “Encoder break”, refer to section 7 of the Powerdrive manual 3871.

A

•

00.02

: Max. speed < 140%

of the motor rated speed

00.07

•

00.12

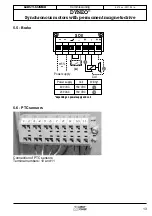

: The switching frequency value must be set according to the following table:

•

00.21

: CURRENT LOOP PROPORTIONAL GAIN =

κ

x kVA x Ld

with: -

κ

= 1 for 400/460V drives,

- kVA : Drive rating (example : 340 for a 340T),

- Ld : inductance value located on the motor nameplate in mH.

The recommended gain value should not be greater than 80 when the stator frequency is lower than 150 Hz.

00.07

(Motor rated speed)

00.12

(Switching frequency)

N.rated

≤

1800 rpm

1800 rpm < N.rated

≤

2400 rpm

2400 rpm < N.rated

≤

3600 rpm

3600 rpm < N.rated

≤

4500 rpm

4500 rpm < N.rated

3 kHz

4 kHz

4,5 kHz

5 kHz

6 kHz

• Before setting the maximum speed,

check that the motor and the machine

can withstand it.

• Respect the supply voltage “Inverter

supply” indicated on the motor nameplate.

Содержание DYNEO

Страница 1: ...DYNEO Synchronous motors with permanent magnets drive Commissioning 4474 en 2011 04 e...

Страница 14: ...Commissioning DYNEO Synchronous motors with permanent magnets drive 14 4474 en 2011 04 e LEROY SOMER...

Страница 15: ...15 Commissioning DYNEO Synchronous motors with permanent magnets drive 4474 en 2011 04 e LEROY SOMER...