Page 18

Charging Using Normal Operating Pressures

and the Approach Method

Outdoor Temp. > 65

F (18

C)

The following procedure is intended as a general guide and

is for use on expansion valve systems only. For best results,

indoor temperature should be 70°F (21°C) to 80°F (26°C).

Monitor system pressures while charging.

1 − Record outdoor ambient temperature using a digital

thermometer.

2 − Attach high pressure gauge set and operate unit for

several minutes to allow system pressures to stabilize.

3 − Compare stabilized pressures with those provided in

table 6, Normal Operating Pressures." Minor varia-

tions in these pressures may be expected due to differ-

ences in installations. Significant differences could

mean that the system is not properly charged or that a

problem exists with some component in the system.

Pressures higher than those listed indicate that the

system is overcharged. Pressures lower than those

listed indicate that the system is undercharged. A tem-

perature/pressure chart for R410A refrigerant is pro-

vided in table 5 for your convenience. Verify adjusted

charge using the approach method.

Approach Method

4 − Use the same digital thermometer you used to check

the outdoor ambient temperature to check the liquid

line temperature.

5 − The difference between the ambient and liquid temper-

atures should match values given in table 5. If the val-

ues don’t agree with the those in table 5, add refriger-

ant to lower the approach temperature, or recover re-

frigerant from the system to increase the approach

temperature. Be aware of the R410A refrigerant cylin-

der. It will be light maroon−colored. Refrigerant should

be added through the vapor valve in the liquid state.

Some R410A cylinders are equipped with a dip

tube which allows you to draw liquid refrigerant

from the bottom of the cylinder without turning the

cylinder upside−down. The cylinder will be marked

if it is equipped with a dip tube.

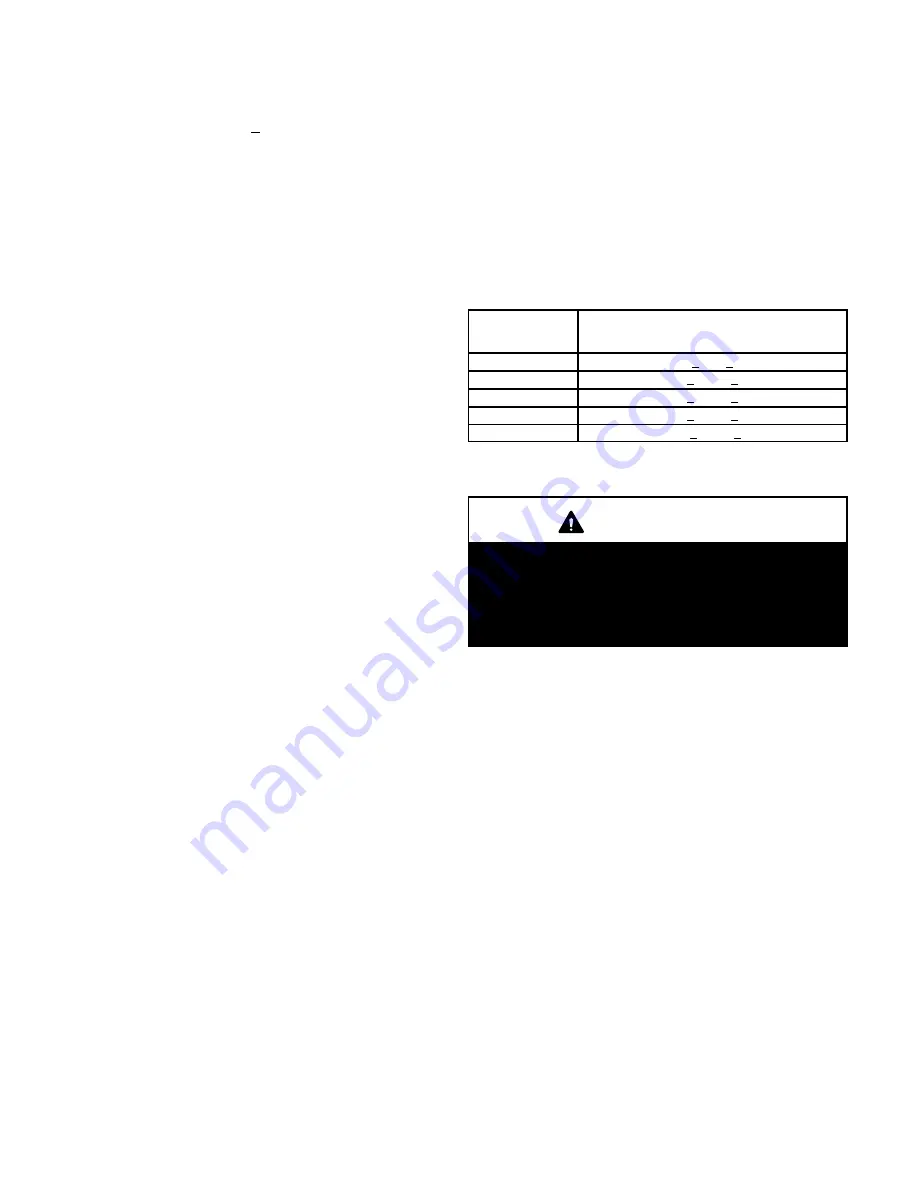

Table 5

Model Number

Second Stage (High Capacity)

Approach Temperature

Liquid Line Temp. − Outdoor Ambient °F (°C)

HSXA19−024

1.9 + 1 (1 + .5)

HSXA19−036

6.2 + 1 (3.5 + .5)

HSXA19−038

7.5 + 1 (4.3 + .5)

HSXA19−048

6.0 + 1 (3.3 + .5)

HSXA19−060

10.0 + 1 (5.6 + .5)

NOTE − For best results, the same electronic thermometer

should be used to check both outdoor ambient and liquid line

temperatures.

IMPORTANT

Use table 6 to perform maintenance checks. Table 6

is not a procedure for charging the system. Minor

variations in these pressures may be due to differ-

ences in installations. Significant deviations could

mean that the system is not properly charged or that

a problem exists with some component in the system.