Page 16

504954M 08/06

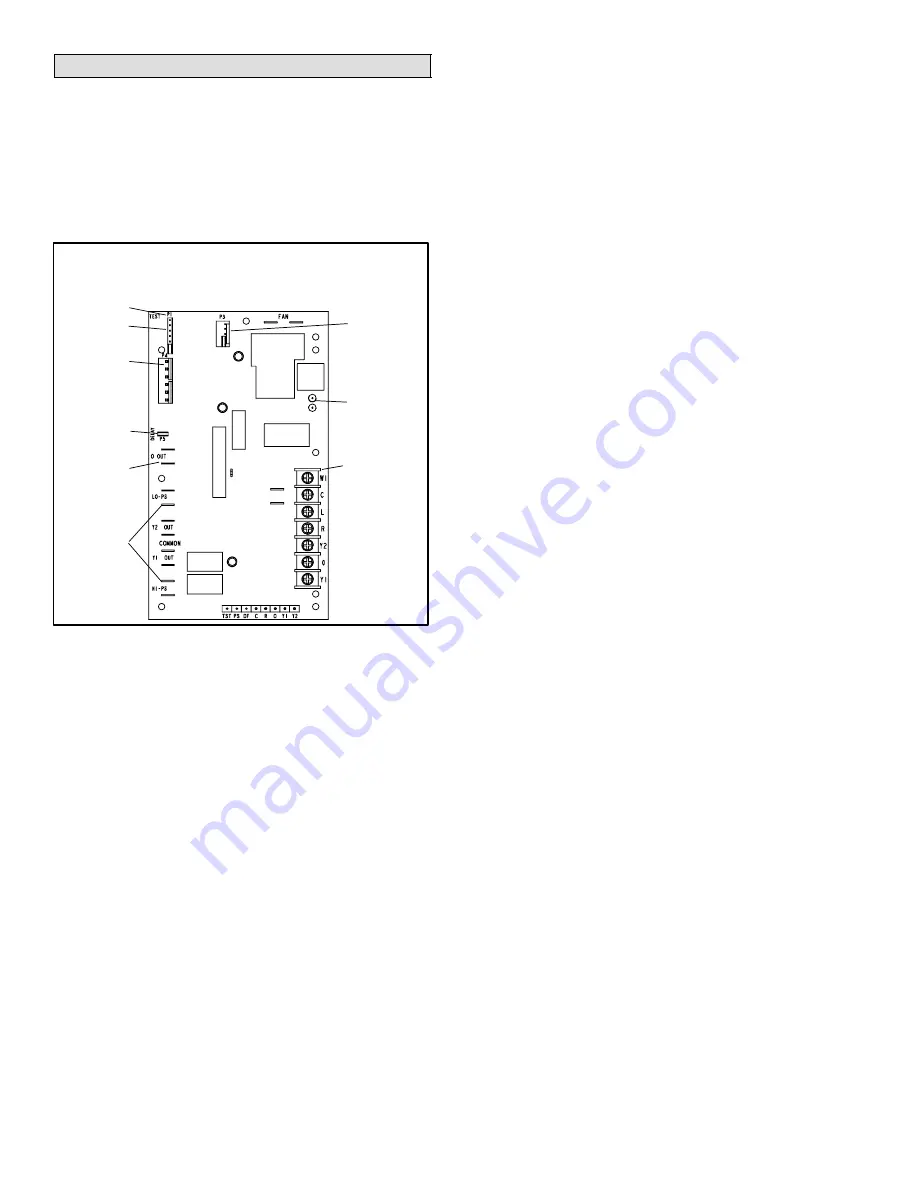

Defrost System

Defrost System Description

The demand defrost controller measures differential tem-

peratures to detect when the system is performing poorly

because of ice build−up on the outdoor coil. The controller

self−calibrates" when the defrost system starts and after

each system defrost cycle. The defrost control board com-

ponents are shown in figure 19.

Defrost Control Board

24V TERMINAL

STRIP

CONNECTIONS

DIAGNOSTIC

LEDS

PRESSURE

SWITCH CIR-

CUIT CONNEC-

TIONS

TEST PINS

Note − Component Locations Vary by Board Manufacture

r.

SENSOR

PLUG IN

(COIL & AM-

BIENT

SENSORS)

Figure 19

REVERSING

VALVE

DELAY

PINS

LOW

AMBIENT

THERMOSTAT

PINS

DEFROST

TERMINATION

PIN SETTINGS

The control monitors ambient temperature, outdoor coil

temperature, and total run time to determine when a de-

frost cycle is required. The coil temperature probe is de-

signed with a spring clip to allow mounting to the outside

coil tubing. The location of the coil sensor is important for

proper defrost operation.

NOTE − The demand defrost board accurately measures

the performance of the system as frost accumulates on the

outdoor coil. This typically will translate into longer running

time between defrost cycles as more frost accumulates on

the outdoor coil before the board initiates defrost cycles.

Defrost Board Diagnostic LEDs

The state (Off, On, Flashing) of two LEDs on the defrost

board (DS1 [Red] and DS2 [Green]) indicate diagnostics

conditions that are described in table 10 (on page 20).

Defrost Board Pressure Switch Connections

The unit’s automatic reset pressure switches (LO PS − S87

and HI PS − S4) are factory−wired into the defrost board on

the LO−PS and HI−PS terminals, respectively.

Low Pressure Switch (LO−PS)

When the low pressure

switch trips, the defrost board will cycle off the compressor,

and the strike counter in the board will count one strike.

The low pressure switch is ignored under the following

conditions:

during the defrost cycle and 90 seconds after the ter-

mination of defrost

when the average ambient sensor temperature is be-

low 15° F (−9°C)

for 90 seconds following the start up of the compressor

during "test" mode

High Pressure Switch (HI−PS)

When the high pressure

switch trips, the defrost board will cycle off the compressor,

and the strike counter in the board will count one strike.

Defrost Board Pressure Switch Settings

High Pressure

(auto reset) − trip at 590 psig; reset at 418

psig.

Low Pressure

(auto reset) − trip at 25 psig; reset at 55

psig.

Pressure Switch 5−Strike Lockout

The internal control logic of the board counts the pressure

switch trips only while the Y1 (Input) line is active. If a pres-

sure switch opens and closes four times during a Y1 (In-

put), the control logic will reset the pressure switch trip

counter to zero at the end of the Y1 (Input). If the pressure

switch opens for a fifth time during the current Y1 (Input),

the control will enter a lockout condition.

The 5−strike pressure switch lockout condition can be reset

by cycling OFF the 24−volt power to the control board or by

shorting the TEST pins between 1 to 2 seconds. All timer

functions (run times) will also be reset.

If a pressure switch opens while the Y1 Out line is en-

gaged, a 5−minute short cycle will occur after the switch

closes.

Defrost System Sensors

Sensors connect to the defrost board through a field-re-

placeable harness assembly that plugs into the board (see

figure 21). Through the sensors, the board detects outdoor

ambient, coil, and discharge temperature fault conditions.

As the detected temperature changes, the resistance

across the sensor changes. Figure 20 shows how the re-

sistance varies as the temperature changes for both type

of sensors. Sensor resistance values can be checked by

ohming across pins shown shown in table 9.