Page 8

504954M 08/06

Isolation Grommets

Locate the provided isolation grommets. Use a knife to slit

the webbing on each grommet. Slide larger grommet onto

vapor line and smaller grommet onto liquid line. Insert

grommets into mullion to isolate refrigerant lines from

sheet metal edges.

WARNING

Polyol ester (POE) oils used with HFC−410A refrig-

erant absorb moisture very quickly. It is very im-

portant that the refrigerant system be kept closed

as much as possible. DO NOT remove line set caps

or service valve stub caps until you are ready to

make connections.

Brazing Connection Procedure

1. The end of the refrigerant line must be cut square and

its internal shape must remain round. The line must be

free of nicks or dents and must be deburred (I.D. and

O.D.)

2. Before making line set connections, use dry nitrogen

to purge the refrigerant piping. This will help to prevent

oxidation and the introduction of moisture into the sys-

tem.

3. Use silver alloy brazing rods (5 or 6 percent

minimum

silver alloy for copper−to−copper brazing or 45 percent

silver alloy for copper−to−brass or copper−to−steel

brazing). Wrap a wet cloth around the valve body and

the copper tube stub. Remove light maroon washers

from service valves and shield light maroon stickers in

order to protect them during brazing. Braze the line set

to the service valve.

4. Quench the joint with water or a wet cloth to prevent

heat damage to the valve core and opening port.

NOTE − The tube end must stay bottomed in the fitting

during final assembly to ensure proper seating, seal-

ing and rigidity.

Refrigerant Metering Device

HPXA16 units may be used in check expansion valve

(CTXV) systems only. See indoor coil installation instruc-

tions and the Lennox engineering handbook for approved

HFC−410A TXV match−ups and application information.

NOTE − HFC−410A systems will not operate properly with

an HCFC−22 valve.

Check Expansion Valve Systems

Check expansion valves equipped with either Chatleff or

flare−type fittings are available from Lennox. Refer to the

Engineering Handbook for applicable expansion valves for

use with specific match-ups.

If you install a check expansion valve with an indoor coil

that includes a fixed orifice, remove the orifice before the

check expansion valve is installed. See figure 13 for instal-

lation of the check expansion valve.

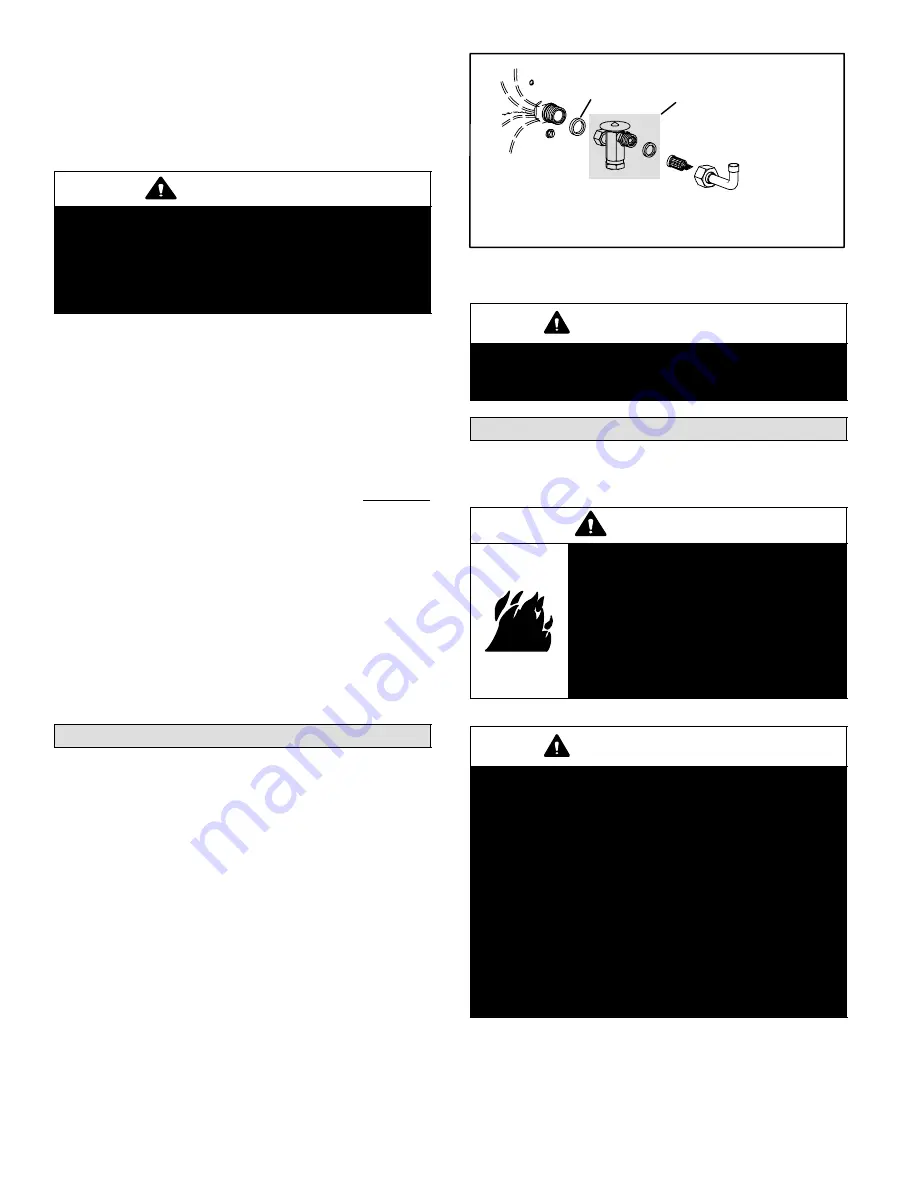

EXPANSION VALVE &

O−RING (See NOTE)

Metering Device Installation

STRAINER

LIQUID LINE

STUB

DISTRIBUTOR

Figure 13

O−RING

NOTE − If necessary, remove HCFC−22 flow control device (fixed

orifice/check expansion valve) from existing line set before installing

HFC−410A approved expansion valve and o−ring.

IMPORTANT

Failure to remove a fixed orifice when installing an

expansion valve on the indoor coil will result in im-

proper operation and damage to the system.

Flushing Existing Line Set & Indoor Coil

NOTE − If the indoor unit line and set are new, skip this sec-

tion and go on to the Manifold Gauge Set section.

WARNING

Danger of fire. Bleeding the refriger-

ant charge from only the high side

may result in the low side shell and

suction tubing being pressurized. Ap-

plication of a brazing torch while

pressurized may result in ignition of

the refrigerant and oil mixture − check

the high and low pressures before un-

brazing.

IMPORTANT

If this unit is being matched with an approved line

set or indoor coil which was previously charged

with HCFC−22 refrigerant, or if it is being matched

with a coil which was manufactured before Janu-

ary of 1999, the coil and line set must be flushed

prior to installation. Take care to empty all existing

traps.

Polyol ester (POE) oils are used in Lennox units

charged with HFC−410A refrigerant. Residual min-

eral oil can act as an insulator, preventing proper

heat transfer. It can also clog the check expansion

valve, reducing system performance and capacity.

Failure to properly flush the system per the in-

structions below will void the warranty.