Page 14

TABLE 4 - GAS PIPE CAPACITY (FT

3

/HR)

Nominal

Iron Pipe Size

Internal

Diameter

Length of Pipe - feet

Iron Pipe Size

inches

Diameter

inches

10

20

30

40

50

60

70

80

90

100

1/4

.364

43

29

24

20

18

16

15

14

13

12

3/8

.493

95

65

52

45

40

36

33

31

29

27

1/2

.622

175

120

97

82

73

66

61

57

53

50

3/4

.824

360

250

200

170

151

138

125

118

110

103

1

1.049

680

465

375

320

285

260

240

220

205

195

1-1/4

1.380

1,400

950

770

660

580

530

490

460

430

400

1-1/2

1.610

2,100

460

1,180

990

900

810

750

690

650

620

2

2.067

3,950

2,750

2,200

1,900

1,680

1,520

1,400

1,300

1,220

1,150

2-1/2

2.469

6,300

4,350

3,520

3,000

2,650

2,400

2,250

2,050

1,950

1,850

3

3.068

11,000

7,700

6,250

5,300

4,750

4,300

3,900

3,700

3,450

3,250

4

4.026

23,000

15,800

12,800

10,900

9,700

8,800

8,100

7,500

7,200

6,700

NOTE-Capacity given in cubic feet of gas per hour and based on 0.60 specific gravity gas.

TABLE 5 - GAS PIPE CAPACITY (M

3

/HR)

Nominal

Iron Pipe Size

Internal

Diameter

Length of Pipe - metres

Iron Pipe Size

inches

Diameter

inches

3

6

9

12

15

18

21

24

27

30

1/2

.622

4.29

3.40

2.74

2.32

2.06

1.87

1.72

1.61

1.50

1.41

3/4

.824

10.20

7.08

5.66

4.81

4.27

3.91

3.54

3.34

3.11

2.91

1

1.049

19.27

13.17

10.62

9.06

8.07

7.36

6.80

6.23

5.80

5.52

1-1/4

1.380

39.67

26.92

21.82

18.70

16.43

15.02

13.88

13.03

12.18

11.33

1-1/2

1.610

59.51

41.37

33.43

28.05

25.50

22.95

21.25

19.55

18.42

17.56

2

2.067

111.93

79.93

62.34

53.84

47.60

43.07

39.67

36.84

34.57

32.58

2-1/2

2.469

178.53

123.27

99.75

85.01

75.09

68.01

63.76

58.09

55.26

52.62

3

3.068

311.72

218.20

117.11

150.19

134.60

121.85

110.52

104.85

97.76

92.10

4

4.026

651.78

447.74

308.89

274.88

249.37

249.37

229.54

212.53

204.03

189.86

NOTE-Capacity given in cubic metres of gas per hour and based on 0.60 specific gravity gas.

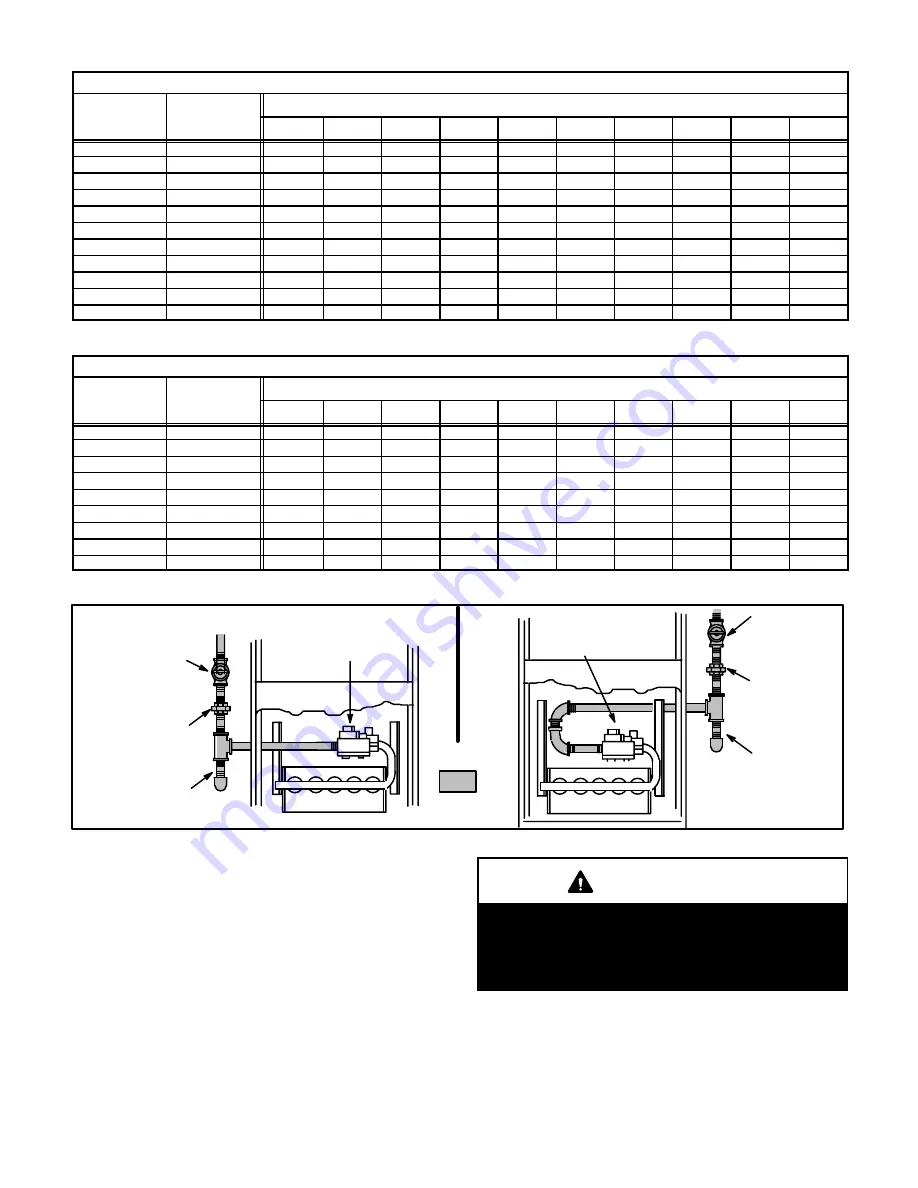

GROUND

JOINT

UNION

AUTOMATIC

GAS VALVE

FIELD

PROVIDED

AND INSTALLED

GROUND

JOINT

UNION

LEFT SIDE PIPING (STANDARD)

RIGHT SIDE PIPING

(ALTERNATE)

AUTOMATIC

GAS VALVE

DRIP LEG

(optional)

MANUAL

MAIN SHUT-OFF VALVE

(With 1/8" RC

Plugged Tap Shown)

MANUAL

MAIN SHUT-OFF

VALVE

(With 1/8" RC

Plugged Tap

Shown)

DRIP LEG

(optional)

FIGURE 18

SOUNDNESS CHECK

After gas piping is completed, carefully check all piping

connections (factory- and field-installed) for gas leaks.

Use a leak detecting solution or other preferred means.

NOTE - In case emergency shutdown is required, shut

down main manual gas valve and disconnect electrical

power to unit. These devices should be properly labeled

by the installer.

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or other sources of igniĆ

tion to check for gas leaks.

The furnace must be isolated from the gas supply system

by closing its individual manual shut-off valve during any

pressure testing of the gas supply system at pressures

equal to or less than 20 in. w.c. (50 mBAR).