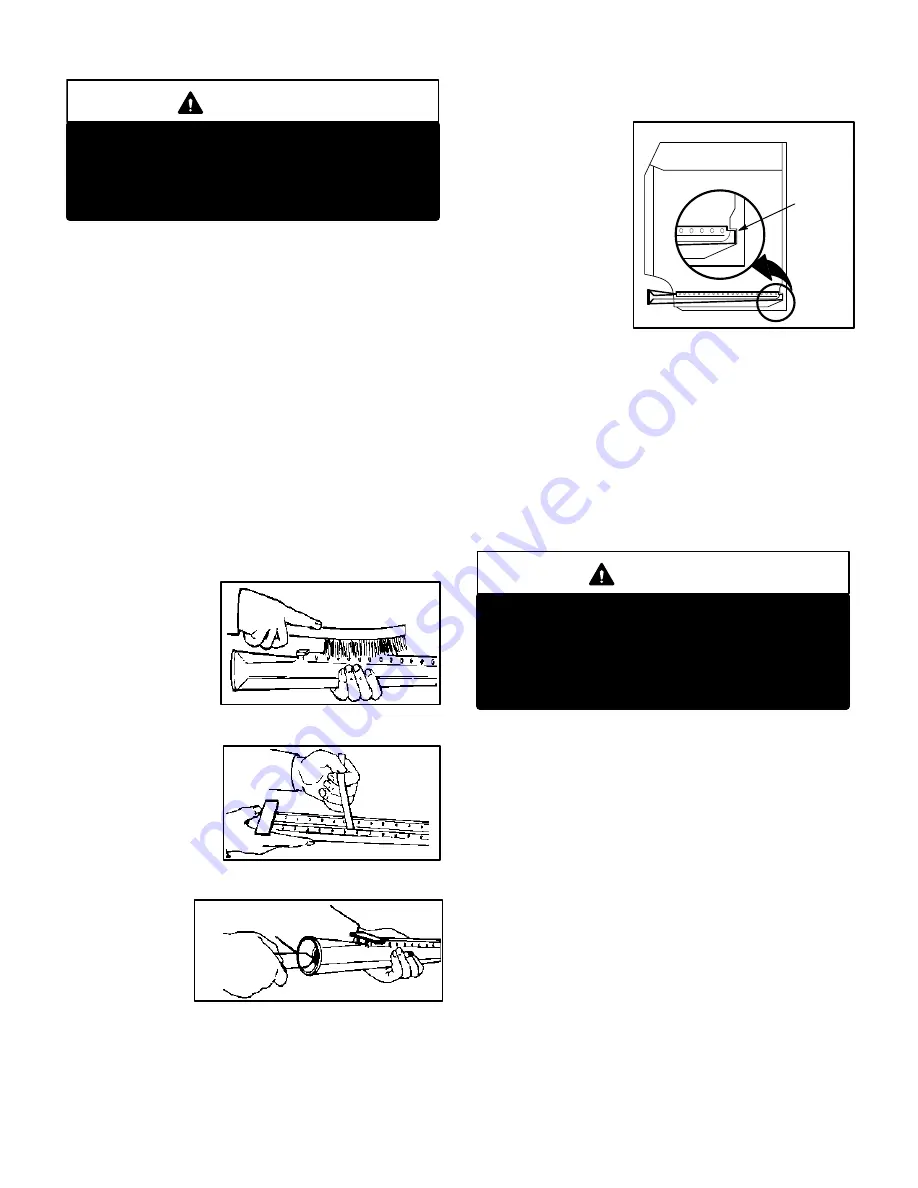

CLEANING TOP

FIGURE 19

CLEANING

PORTS

FIGURE 20

CLEANING INSIDE

FIGURE 21

FIGURE 22

BURNER SLOT ENGAGEMENT

ENGAGE

BURNER

IN SLOT

Page 11

CAUTION

Potential for unit damage.

Use extreme care when opening damper door to

prevent permanent damage to the damper door.

Can cause damage to damper motor resulting in

improper furnace operation.

6- Remove flue restrictor over flue outlet (Ć50 only).

7- Gas manifold, gas valve and burners do not need to be

removed and can be left in place.

8- Insert a 2 ft. steel rod with a 20 in. length of chain atĆ

tached to one end into top opening of heat exchanger.

Refer to figure 18.

9- Shake rod to drop chain through clamshell into burner

cavity in bottom of heat exchanger.

10- Attach bottom of chain to 2 ft. (600 mm) rod.

11- Push and pull the rods back and forth and up and down

with a vigorous motion. The chain will dislodge the soot

and scale deposits inside the heat exchanger. Repeat

for each clamshell.

12- With a shop vacuum or rags, clean out soot and scale

deposits from bottom of heat exchanger.

To clean burners:

1- Disconnect gas piping.

2- Remove screws

holding gas manĆ

ifold in place and

pull burners from

heat exchanger.

3- Clean top of burnĆ

er ports with a wire

brush. See figure 19.

4- Clean burner ports

by inserting a cleanĆ

ing tool (made from

a piece of sheet

metal cut to fit the

burner ports) and

work in and out of

each port. See figure 20.

5- Clean inside of

each burner

with a bottle

cleaning

brush. See figĆ

ure 21.

6- Replace burners making sure to fully engage in rear

receiving slot in heat exchanger. See figure 22. ReseĆ

cure gas manifold and supply piping.

7- Resecure damper

assembly, damper

prove switch cover

and burner box

top. Carefully open

damper by hand to

ensure that the

damper

spring

closes

damper

correctly and that

the damper prove

switch is engaged

when damper is open.

8- Install flue restrictor (Ć50 models only).

9- Before replacing draft hood, flue pipe and access

panels, inspect draft hood gasket. Replace gasket if

necessary.

10- Carefully check all piping connections (factory and

field) for gas leaks. Use a leak detecting solution or othĆ

er preferred means.

11- Turn on gas and electrical supply.

CAUTION

Potential for gas leaks, fire or explosion.

Some soaps used for leak detection are corrosive

to certain metals. Carefully clean piping thorĆ

oughly after leak detection has been completed.

Can cause damage to piping resulting in gas

leaks, fire or explosion.

C-Supply Air Blower

1- Check and clean blower wheel.

2- Motors used on the Lennox G17 series units are permaĆ

nently lubricated and need no further lubrication.

A - Flue and Chimney

Flue must conform to all AGA/GAMA venting requireĆ

ments for Category I Central Furnaces." Flue pipe deteriĆ

orates from the inside out and must be disconnected in orĆ

der to check thoroughly. Check flue pipe, chimney and all

connections for tightness and to make sure there is no

blockage or leaks.

B - Electrical

1 - Check all wiring for loose connections.

2 - Check for correct voltage.

3 - Check amp-draw on blower motor.