6

1-2 FEATURES & BENEFITS

Your new laminator has several standard features that set it apart from other models.

••••

Variable speed

The laminator operates at any speed up to 7 feet per minute. Thicker

films are generally applied better at mid-range to lower speeds, while 1.5-mil film should

be applied at mid-range to higher speeds.

••••

LCD temperature display

makes it easy to set and maintain the correct temperature.

The indicator light inside the heat switch comes on as the machine warms up. When set

temperature is reached, the indicator light turns off.

••••

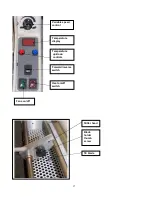

Simple controls

Conveniently placed switches provide a compact, reliable control pad.

Icons and international symbols are used for controls and safety warnings.

••••

Slitters

The slitters remove the side scrap from both sides of each sheet as it goes

through the laminator. This greatly reduces the amount of time required for trimming.

••••

Easy threading

Since threading can be the most difficult task in using a laminator, the

Premier 4 has built in threading aids. The top idler is guarded from the top heat shoe for

safety and easy threading. The bottom idler is attached to the feed tray. Once the upper

and lower webs of film have been run through the machine, bottom idler threading is

automatic when the operator puts the feed tray on the machine.

••••

Forced air-cooling

allows laminating with thicker films. Without a cooling system,

thicker films will warp or ripple because they are still too hot when they come out the back

of the laminator. The three fans in the 25-inch Premier 4 provide a more effective cooling

system than any other machine in its class.

••••

Ease of cleaning

The silicone rubber rollers and the Teflon-coated heat shoes on the

laminator should be cleaned regularly.

••••

Attached safety shield

The polycarbonate shield is clear so operators can see their

work. It does not conduct heat, providing protection from hot areas, and it’s fixed to the

machine so operators will naturally put it in the guard position before laminating.

••••

Lamination pressure

The rubber rollers are spring-loaded and preset to ensure correct

and even lamination pressure. The pressure is easy to adjust if required when performing

routine maintenance.

••••

Supply roll tension controls

Supply roll tension is easy to adjust by simply tightening or

loosening the tension control knobs on the supply roll mandrels.

Содержание Premier 4

Страница 25: ...25 5 3 FILM THREADING DIAGRAM ...

Страница 43: ...43 ...