3

www.lasertools.co.uk

Specifications:

Usable oil capacity:

1500cc

Maximum hydraulic pressure:

700 bar

Output Flow Rate (no load):

0 bar:

1.3 litres/min

700 bar:

0.24 litres/min

Hydraulic hose length:

1.8m

Air pressure range:

7-11kg/cm² (100-156psi)

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

(B)

weekly,

then operate the pump.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

Refer to Figure 1:

Connect the hydraulic coupling

(D)

to the corresponding coupling on the

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

enter the system.

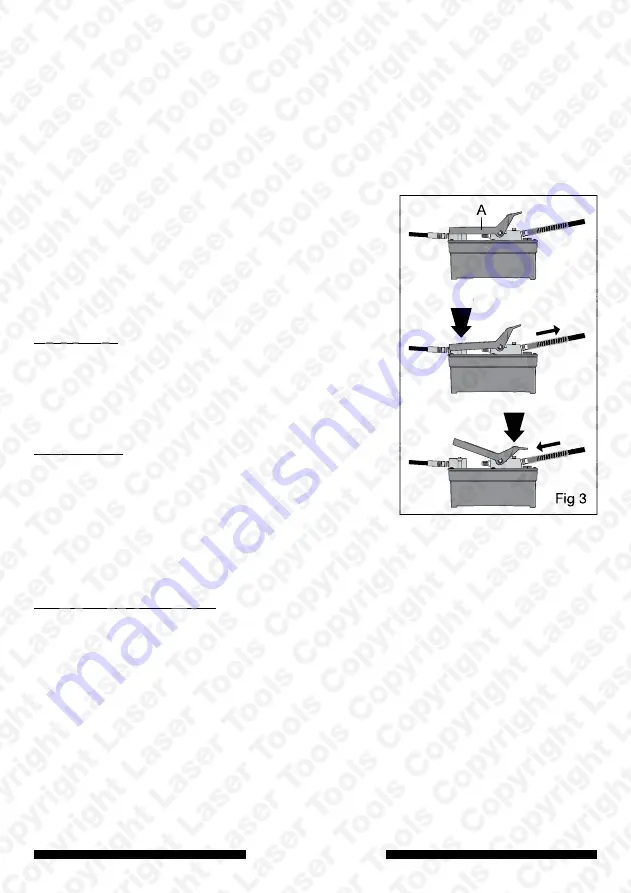

Refer to Figure 3:

depressing the foot pedal

(A)

at the

air inlet end (marked PUMP) activates the ram on the

cylinder/attachment. To activate the ram a small distance,

tap the foot pedal until the ram reaches the desired

distance. Retracting the ram (releasing the hydraulic

pressure) is carried out by depressing the foot pedal

(A)

at the opposite end (marked RELEASE).

Maintenance:

The greatest single cause of failure in hydraulic pumps is

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

attachments and accessories clean and free from oil and

dirt. Ensure that any unused couplers or adaptors are

sealed with thread protectors, and dust covers.

Filling with oil:

Check the fluid level after every 10 hours of use.

Drain and replenish the recommended hydraulic fluid

after approximately 300 hours of use.

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

(G)

. Top up with hydraulic oil

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

vented cap with all cylinders retracted.

Bleeding air from the system:

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

then operate the pump.

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

Refer to Figure 1:

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

then operate the pump.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

then operate the pump.

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

enter the system.

Refer to Figure 3:

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

enter the system.

Refer to Figure 1:

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

Refer to Figure 1:

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

100psi; the air supply should be filtered, regulated and lubricated.

Refer to Figure 1:

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

then operate the pump.

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

then operate the pump.

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

cylinder/attachment. To activate the ram a small distance,

tap the foot pedal until the ram reaches the desired

air inlet end (marked PUMP) activates the ram on the

cylinder/attachment. To activate the ram a small distance,

tap the foot pedal until the ram reaches the desired

Refer to Figure 3:

air inlet end (marked PUMP) activates the ram on the

cylinder/attachment. To activate the ram a small distance,

Refer to Figure 3:

air inlet end (marked PUMP) activates the ram on the

enter the system.

Refer to Figure 3:

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

enter the system.

Refer to Figure 1:

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

Refer to Figure 1:

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

100psi; the air supply should be filtered, regulated and lubricated.

Connect the hydraulic coupling

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

at the opposite end (marked RELEASE).

pressure) is carried out by depressing the foot pedal

at the opposite end (marked RELEASE).

distance. Retracting the ram (releasing the hydraulic

pressure) is carried out by depressing the foot pedal

distance. Retracting the ram (releasing the hydraulic

distance. Retracting the ram (releasing the hydraulic

pressure) is carried out by depressing the foot pedal

tap the foot pedal until the ram reaches the desired

distance. Retracting the ram (releasing the hydraulic

cylinder/attachment. To activate the ram a small distance,

tap the foot pedal until the ram reaches the desired

air inlet end (marked PUMP) activates the ram on the

cylinder/attachment. To activate the ram a small distance,

Refer to Figure 3:

air inlet end (marked PUMP) activates the ram on the

Refer to Figure 3:

depressing the foot pedal

depressing the foot pedal

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

Connect the hydraulic coupling

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

100psi; the air supply should be filtered, regulated and lubricated.

Connect the hydraulic coupling

100psi; the air supply should be filtered, regulated and lubricated.

Connect the hydraulic coupling

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

The greatest single cause of failure in hydraulic pumps is

Maintenance:

The greatest single cause of failure in hydraulic pumps is

at the opposite end (marked RELEASE).

Maintenance:

at the opposite end (marked RELEASE).

pressure) is carried out by depressing the foot pedal

pressure) is carried out by depressing the foot pedal

at the opposite end (marked RELEASE).

pressure) is carried out by depressing the foot pedal

at the opposite end (marked RELEASE).

distance. Retracting the ram (releasing the hydraulic

pressure) is carried out by depressing the foot pedal

tap the foot pedal until the ram reaches the desired

distance. Retracting the ram (releasing the hydraulic

cylinder/attachment. To activate the ram a small distance,

tap the foot pedal until the ram reaches the desired

air inlet end (marked PUMP) activates the ram on the

cylinder/attachment. To activate the ram a small distance,

depressing the foot pedal

air inlet end (marked PUMP) activates the ram on the

depressing the foot pedal

depressing the foot pedal

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

Connect the hydraulic coupling

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

Connect the hydraulic coupling

100psi; the air supply should be filtered, regulated and lubricated.

Connect the hydraulic coupling

100psi; the air supply should be filtered, regulated and lubricated.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

sealed with thread protectors, and dust covers.

attachments and accessories clean and free from oil and

dirt. Ensure that any unused couplers or adaptors are

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

attachments and accessories clean and free from oil and

The greatest single cause of failure in hydraulic pumps is

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

attachments and accessories clean and free from oil and

The greatest single cause of failure in hydraulic pumps is

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

Maintenance:

The greatest single cause of failure in hydraulic pumps is

Maintenance:

Maintenance:

at the opposite end (marked RELEASE).

at the opposite end (marked RELEASE).

pressure) is carried out by depressing the foot pedal

at the opposite end (marked RELEASE).

distance. Retracting the ram (releasing the hydraulic

pressure) is carried out by depressing the foot pedal

tap the foot pedal until the ram reaches the desired

distance. Retracting the ram (releasing the hydraulic

cylinder/attachment. To activate the ram a small distance,

tap the foot pedal until the ram reaches the desired

air inlet end (marked PUMP) activates the ram on the

cylinder/attachment. To activate the ram a small distance,

depressing the foot pedal

air inlet end (marked PUMP) activates the ram on the

depressing the foot pedal

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

Connect the hydraulic coupling

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

Connect the hydraulic coupling

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

100psi; the air supply should be filtered, regulated and lubricated.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

Check the fluid level after every 10 hours of use.

Drain and replenish the recommended hydraulic fluid

Filling with oil:

Filling with oil:

Check the fluid level after every 10 hours of use.

Filling with oil:

Filling with oil:

sealed with thread protectors, and dust covers.

dirt. Ensure that any unused couplers or adaptors are

sealed with thread protectors, and dust covers.

attachments and accessories clean and free from oil and

dirt. Ensure that any unused couplers or adaptors are

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

attachments and accessories clean and free from oil and

The greatest single cause of failure in hydraulic pumps is

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

The greatest single cause of failure in hydraulic pumps is

The greatest single cause of failure in hydraulic pumps is

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

The greatest single cause of failure in hydraulic pumps is

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

The greatest single cause of failure in hydraulic pumps is

at the opposite end (marked RELEASE).

pressure) is carried out by depressing the foot pedal

at the opposite end (marked RELEASE).

pressure) is carried out by depressing the foot pedal

at the opposite end (marked RELEASE).

distance. Retracting the ram (releasing the hydraulic

pressure) is carried out by depressing the foot pedal

tap the foot pedal until the ram reaches the desired

distance. Retracting the ram (releasing the hydraulic

cylinder/attachment. To activate the ram a small distance,

tap the foot pedal until the ram reaches the desired

depressing the foot pedal

air inlet end (marked PUMP) activates the ram on the

cylinder/attachment. To activate the ram a small distance,

depressing the foot pedal

air inlet end (marked PUMP) activates the ram on the

depressing the foot pedal

(A)

(A)

Connect the hydraulic coupling

(D)

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

(D)

to the corresponding coupling on the

100psi; the air supply should be filtered, regulated and lubricated.

to the corresponding coupling on the

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

after approximately 300 hours of use.

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

Drain and replenish the recommended hydraulic fluid

after approximately 300 hours of use.

Drain and replenish the recommended hydraulic fluid

after approximately 300 hours of use.

Check the fluid level after every 10 hours of use.

Drain and replenish the recommended hydraulic fluid

Filling with oil:

Filling with oil:

Check the fluid level after every 10 hours of use.

Filling with oil:

sealed with thread protectors, and dust covers.

dirt. Ensure that any unused couplers or adaptors are

sealed with thread protectors, and dust covers.

attachments and accessories clean and free from oil and

dirt. Ensure that any unused couplers or adaptors are

attachments and accessories clean and free from oil and

attachments and accessories clean and free from oil and

dirt. Ensure that any unused couplers or adaptors are

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

attachments and accessories clean and free from oil and

The greatest single cause of failure in hydraulic pumps is

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

The greatest single cause of failure in hydraulic pumps is

at the opposite end (marked RELEASE).

pressure) is carried out by depressing the foot pedal

at the opposite end (marked RELEASE).

pressure) is carried out by depressing the foot pedal

at the opposite end (marked RELEASE).

distance. Retracting the ram (releasing the hydraulic

pressure) is carried out by depressing the foot pedal

cylinder/attachment. To activate the ram a small distance,

tap the foot pedal until the ram reaches the desired

distance. Retracting the ram (releasing the hydraulic

cylinder/attachment. To activate the ram a small distance,

tap the foot pedal until the ram reaches the desired

air inlet end (marked PUMP) activates the ram on the

cylinder/attachment. To activate the ram a small distance,

at the

air inlet end (marked PUMP) activates the ram on the

at the

air inlet end (marked PUMP) activates the ram on the

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

to the corresponding coupling on the

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

to the corresponding coupling on the

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

100psi; the air supply should be filtered, regulated and lubricated.

to the corresponding coupling on the

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

100psi; the air supply should be filtered, regulated and lubricated.

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

10 oil. Otherwise add a few drops of the recommended oil to the air inlet port

(B)

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

(B)

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

vented cap with all cylinders retracted.

Bleeding air from the system:

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

vented cap with all cylinders retracted.

with cylinder/attachment lower. Remove oil reservoir filler cap

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

after approximately 300 hours of use.

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

after approximately 300 hours of use.

Check the fluid level after every 10 hours of use.

Drain and replenish the recommended hydraulic fluid

Check the fluid level after every 10 hours of use.

Check the fluid level after every 10 hours of use.

sealed with thread protectors, and dust covers.

sealed with thread protectors, and dust covers.

dirt. Ensure that any unused couplers or adaptors are

sealed with thread protectors, and dust covers.

dirt. Ensure that any unused couplers or adaptors are

sealed with thread protectors, and dust covers.

attachments and accessories clean and free from oil and

dirt. Ensure that any unused couplers or adaptors are

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

attachments and accessories clean and free from oil and

The greatest single cause of failure in hydraulic pumps is

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

The greatest single cause of failure in hydraulic pumps is

pressure) is carried out by depressing the foot pedal

distance. Retracting the ram (releasing the hydraulic

pressure) is carried out by depressing the foot pedal

distance. Retracting the ram (releasing the hydraulic

pressure) is carried out by depressing the foot pedal

cylinder/attachment. To activate the ram a small distance,

cylinder/attachment. To activate the ram a small distance,

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

to the corresponding coupling on the

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

to the corresponding coupling on the

to the corresponding coupling on the

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

to the corresponding coupling on the

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

weekly,

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

weekly,

an automatic air line oiler as close to the hydraulic pump as possible. Set the oiler to feed

approximately one drop of oil per minute into the system. Use a high quality air line oil or SAE

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

Bleeding air from the system:

Bleeding air from the system:

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

Bleeding air from the system:

Bleeding air from the system:

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

vented cap with all cylinders retracted.

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

vented cap with all cylinders retracted.

with cylinder/attachment lower. Remove oil reservoir filler cap

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

after approximately 300 hours of use.

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

Drain and replenish the recommended hydraulic fluid

after approximately 300 hours of use.

Check the fluid level after every 10 hours of use.

Drain and replenish the recommended hydraulic fluid

after approximately 300 hours of use.

Check the fluid level after every 10 hours of use.

Drain and replenish the recommended hydraulic fluid

Check the fluid level after every 10 hours of use.

sealed with thread protectors, and dust covers.

sealed with thread protectors, and dust covers.

dirt. Ensure that any unused couplers or adaptors are

sealed with thread protectors, and dust covers.

attachments and accessories clean and free from oil and

dirt. Ensure that any unused couplers or adaptors are

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

attachments and accessories clean and free from oil and

The greatest single cause of failure in hydraulic pumps is

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

The greatest single cause of failure in hydraulic pumps is

(A)

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

to the corresponding coupling on the

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

to the corresponding coupling on the

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

Connect the workshop air supply to the hydraulic pump. Minimum air pressure should be

Specifications:

Specifications:

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

Bleeding air from the system:

Bleeding air from the system:

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

Bleeding air from the system:

Bleeding air from the system:

vented cap with all cylinders retracted.

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

vented cap with all cylinders retracted.

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

vented cap with all cylinders retracted.

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

after approximately 300 hours of use.

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

Drain and replenish the recommended hydraulic fluid

after approximately 300 hours of use.

Check the fluid level after every 10 hours of use.

Drain and replenish the recommended hydraulic fluid

Check the fluid level after every 10 hours of use.

Check the fluid level after every 10 hours of use.

Drain and replenish the recommended hydraulic fluid

Check the fluid level after every 10 hours of use.

Drain and replenish the recommended hydraulic fluid

Check the fluid level after every 10 hours of use.

sealed with thread protectors, and dust covers.

dirt. Ensure that any unused couplers or adaptors are

sealed with thread protectors, and dust covers.

dirt. Ensure that any unused couplers or adaptors are

attachments and accessories clean and free from oil and

dirt. Ensure that any unused couplers or adaptors are

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

attachments and accessories clean and free from oil and

The greatest single cause of failure in hydraulic pumps is

dirt ingress. Keep the pump, hydraulic oil lines, cylinder,

cylinder/attachment. Ensure that both couplings are completely clean so that no dirt can

to the corresponding coupling on the

Output Flow Rate (no load):

0 bar:

Maximum hydraulic pressure:

Output Flow Rate (no load):

Usable oil capacity:

Maximum hydraulic pressure:

Specifications:

Usable oil capacity:

Specifications:

Specifications:

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

Bleeding air from the system:

Bleeding air from the system:

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

Bleeding air from the system:

Bleeding air from the system:

vented cap with all cylinders retracted.

Bleeding air from the system:

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

vented cap with all cylinders retracted.

with cylinder/attachment lower. Remove oil reservoir filler cap

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

Drain and replenish the recommended hydraulic fluid

Check the fluid level after every 10 hours of use.

Drain and replenish the recommended hydraulic fluid

Check the fluid level after every 10 hours of use.

Hydraulic hose length:

Air pressure range:

700 bar:

Hydraulic hose length:

700 bar:

700 bar:

Hydraulic hose length:

0 bar:

700 bar:

Output Flow Rate (no load):

0 bar:

Output Flow Rate (no load):

Maximum hydraulic pressure:

Output Flow Rate (no load):

Usable oil capacity:

Maximum hydraulic pressure:

Usable oil capacity:

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

vented cap with all cylinders retracted.

vented cap with all cylinders retracted.

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

with cylinder/attachment lower. Remove oil reservoir filler cap

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

Drain and replenish the recommended hydraulic fluid

Air pressure range:

Hydraulic hose length:

Air pressure range:

Air pressure range:

Hydraulic hose length:

Air pressure range:

Hydraulic hose length:

Output Flow Rate (no load):

Output Flow Rate (no load):

Maximum hydraulic pressure:

Maximum hydraulic pressure:

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

with cylinder/attachment lower. Remove oil reservoir filler cap

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

with cylinder/attachment lower. Remove oil reservoir filler cap

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

with cylinder/attachment lower. Remove oil reservoir filler cap

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

Air pressure range:

Air pressure range:

Hydraulic hose length:

Air pressure range:

Hydraulic hose length:

Output Flow Rate (no load):

Output Flow Rate (no load):

Maximum hydraulic pressure:

1500cc

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

with cylinder/attachment lower. Remove oil reservoir filler cap

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

(G)

. Top up with hydraulic oil

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

1.3 litres/min

700 bar

700 bar

1500cc

700 bar

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

. Top up with hydraulic oil

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

. Top up with hydraulic oil

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

7-11kg/cm² (100-156psi)

1.8m

7-11kg/cm² (100-156psi)

0.24 litres/min

1.8m

1.3 litres/min

0.24 litres/min

1.3 litres/min

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

To remove the air, connect to a cylinder/attachment and run the system through several

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

. Top up with hydraulic oil

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

. Top up with hydraulic oil

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

www.lasertools.co.uk

www.lasertools.co.uk

www.lasertools.co.uk

www.lasertools.co.uk

7-11kg/cm² (100-156psi)

0.24 litres/min

0.24 litres/min

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

only - do not use engine oil or brake fluid. The oil level is correct at 12.7mm (1/2") below the

Ensure cylinder on cylinder/attachment is fully retracted. Place pump in an upright position

. Top up with hydraulic oil

www.lasertools.co.uk

www.lasertools.co.uk

www.lasertools.co.uk

www.lasertools.co.uk

7-11kg/cm² (100-156psi)

7-11kg/cm² (100-156psi)

7-11kg/cm² (100-156psi)

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

To remove the air, connect to a cylinder/attachment and run the system through several

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

To remove the air, connect to a cylinder/attachment and run the system through several

After filling, or after prolonged use, air may have accumulated within the hydraulic system.

www.lasertools.co.uk

www.lasertools.co.uk

www.lasertools.co.uk

www.lasertools.co.uk

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

be at a lower level that the pump to allow air to be released through the pump oil reservoir.

cycles (extending and retracting the cylinder) free of any load. The cylinder/attachment must

3