Section 1: Assembly & Set-Up

SGC1560, SGC1572, & SGC1584 Claw Grapples380-074M

4/4/23

15

Purge Hydraulic System of Air

Figure 1-7

78931

Check Equipment Clearances

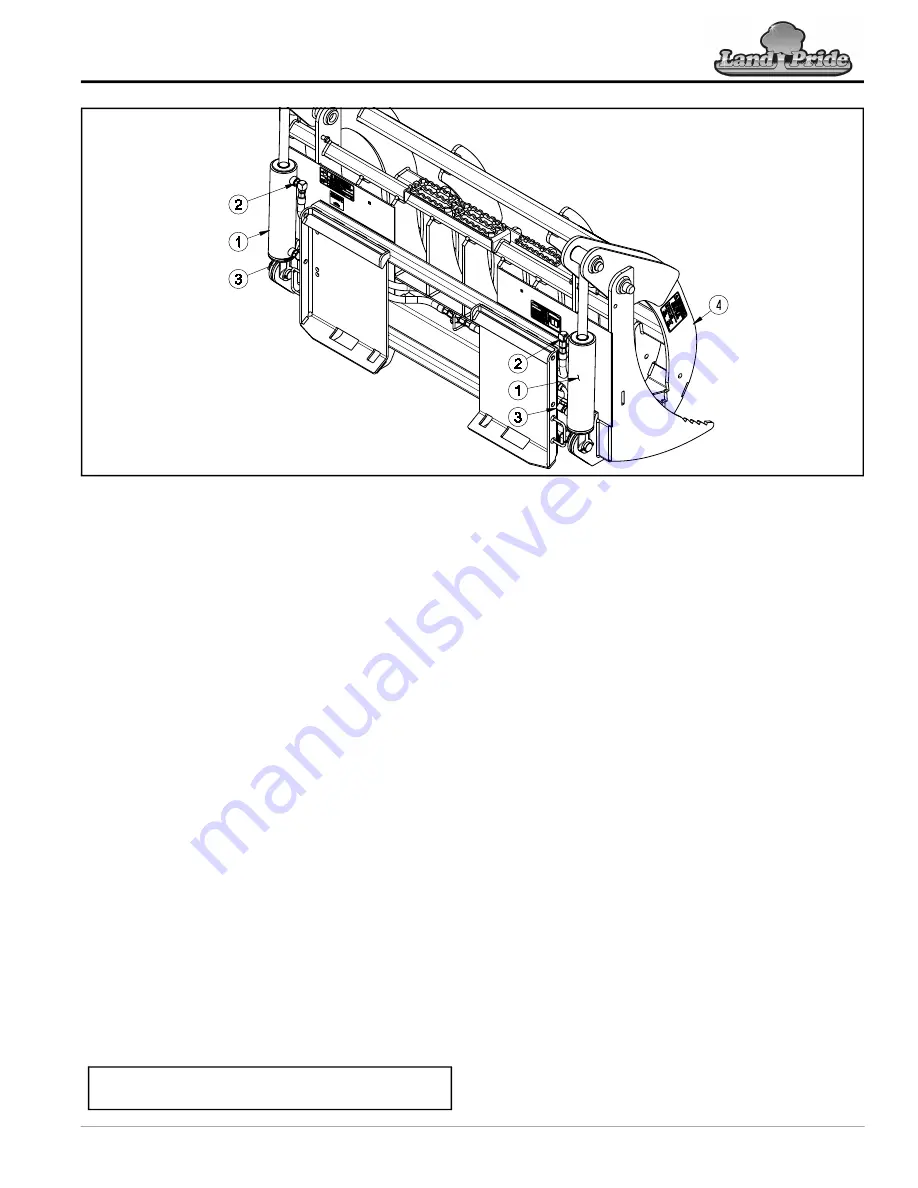

Refer to Figure 1-7:

It is important to check clearance before putting the

grapple into operation. Make sure hoses are long enough

and won’t become pinched or entangled in the

equipment. Also, make sure the grapple does not come

in contact with the power machine by carefully going

through its full range of motions.

1. Visually inspect hydraulic hoses for possible pinch

points and shortness. Make hose adjustments before

putting equipment into service.

2. Start the power machine and raise grapple

approximately 12" (30 cm) off the ground.

3. If necessary, have someone stand nearby that can

motion for the operator to stop if a problem develops

while completing steps 4-7 below.

4. Fully extend grapple cylinders (#1) to fully close the

grapple jaw (#4).

5. Fully extend and retract loader hitch plate cylinders

while watching for equipment interferences. Make

sure grapple hoses are long enough and do not

become pinched through the full range of the loader

hitch plate motion.

6. Fully retract grapple cylinders (#1) to pivot grapple

jaw (#4) fully open and repeat step 5.

7.

Raise loader arms fully up and repeat steps 4-6.

Purge Hydraulic System

Refer to Figure 1-7:

IMPORTANT:

The grapple hydraulic system may

contain air causing erratic, cylinder movement.

If cylinders (#1) operated erratically while checking

clearances, then purge the hydraulic system as follows:

1. Fully extend hydraulic cylinders (#1) to close jaw (#4)

as shown.

2. Shut power machine down according to

3. Loosen elbows (#2) at the rod end of hydraulic

cylinders (#1).

4. Return to the operator’s seat, fasten seat belt, and

start power machine.

5. Slowly retract hydraulic cylinders (#1) until all

trapped air is purged out through elbow fittings (#2).

6. Shut power machine down according to

7.

Tighten elbow fittings (#2).

8. Fully retract hydraulic cylinders (#1) to fully open

grapple claw (#4).

9. Raise loader arms and tilt top of loader hitch plate

forward until grapple and opened claw are facing the

ground. Slowly lower loader arms until the grapple

and opened claw are resting solidly against the

ground.

10. Repeat Step 2, then loosen elbow fittings (#3) at the

base end of hydraulic cylinders (#1).

11. Repeat Step 4, then slowly extend hydraulic

cylinders (#1) until all trapped air is purged out

through elbow fittings (#3).

12. Repeat Step 6, then tighten elbow fittings (#3).

13. If cylinders still operate erratically, repeat steps 1-12.