Section 1: Assembly & Set-Up

RCFM4014 Rotary Cutter 326-730M

12/11/18

15

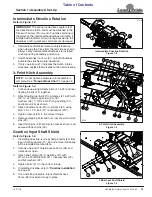

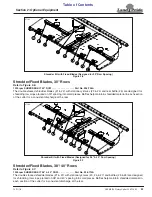

Installation of End Tailwheels for 30" Rows

Figure 1-8

End Tailwheels for 30" Rows

When setting cutter up for 30" rows, the center of the end

tailwheels should be mounted 23 1/2" from each end of

tool bar (#4) or 60" left and right of center.

1.

Attach center of trailing arm (#3) 23 1/2" from left end

of rear tool bar (#4) with 4" tube clamp (#7), 5/8"-11 x

2" GR5 bolts (#8), flat washers (#10), and hex lock

nuts (#10). Make sure center of trailing arm is 23 1/2"

from end of rear tool bar and draw all six nuts up

snug. Do not tighten nuts until step #2.

2. Tighten the center two locknuts (#9) and then the

four corner locknuts (#10) in a crisscross pattern.

3. Repeat step 2 making sure all six nuts are tightened

to the correct torque.

4. Install tailwheel washer (#5) over tailwheel

spindle (#1).

5. Insert tailwheel spindle (#1) into trailing arm (#3).

Push tailwheel up until adjusting collar (#2) is against

the trailing arm (#3).

6. Lower top collar (#6) over tailwheel spindle (#1) until

against the trailing arm (#3).

7.

Secure top collar (#6) with 3/8"-16 x 3 1/4" GR8

bolt (#11) and nylock nut (#9). Tighten nylock nut to

the correct torque.

8. Repeat steps 1-7 for the right-hand side.

37159

IMPORTANT:

below must be followed when

tightening Lock nuts (#10).

IMPORTANT:

Discard hardware mounting tailwheel

to shipping crate. Use bolts, flat washers, and

locknuts in bolt bag to mount tailwheel to cutter axle.

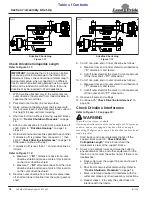

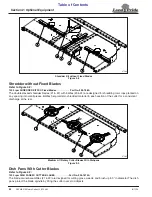

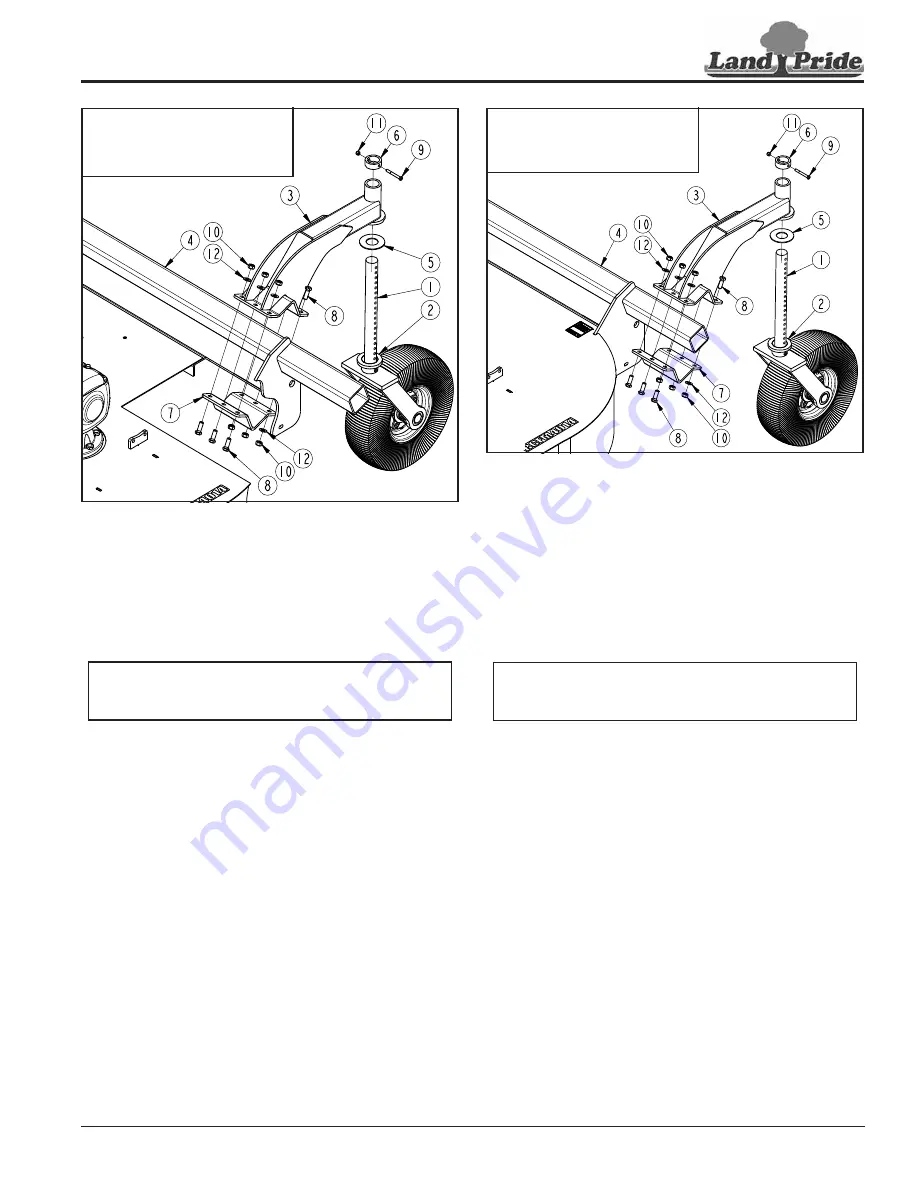

Installation of End Tailwheels for 38" & 40" Rows

Figure 1-9

End Tailwheels for 38" & 40" Rows

When setting cutter up for 38" or 40" rows, the center of

the end tailwheels should be mounted 7 1/2" from each

end of tool bar (#4) for 38" rows and 3 1/2" from each end

of toolbar for 40" rows. Another way to measure it is, 76"

left and right of center for 38" rows and 80" left and right

of center for 40" rows.

1.

Attach center of trailing arm (#3) 7 1/2" for 38" row

spacing or 3 1/2" for 40" row spacing from left end of

rear tool bar (#4) with 4" tube clamp (#7), 5/8"-11 x 2"

GR5 bolts (#8), flat washers (#12), and hex lock

nuts (#10). Make sure center of trailing arm is 7 1/2"

or 3 1/2" from end of rear tool bar and draw all six

nuts up snug. Do not tighten nuts until step #2.

2. Tighten the center two locknuts (#10) and then the

four corner locknuts (#10) in a crisscross pattern.

3. Repeat step 2 making sure all six nuts are tightened

to the correct torque.

4. Install tailwheel washer (#5) over spindle (#1).

5. Insert tailwheel spindle (#1) into trailing arm (#3).

Push tailwheel up until adjusting collar (#2) is against

trailing arm (#3).

6. Lower top collar (#6) over tailwheel spindle (#1) until

against trailing arm (#3).

7.

Secure top collar (#6) with 3/8"-16 x 3 1/4" GR8

bolt (#11) and nylock nut (#9). Tighten nylock nut to

the correct torque.

8. Repeat steps 1-7 for the right-hand side.

37158

IMPORTANT:

below must be followed when

tightening Lock nuts (#10).

IMPORTANT:

Discard hardware mounting tailwheel

to shipping crate. Use bolts, flat washers, and

locknuts in bolt bag to mount tailwheel to cutter axle.