Section 5: Maintenance & Lubrication

AFM4211 All-Flex Grooming Mower 315-507M

3/8/23

38

Driveline Protection

DANGER

!

To avoid serious injury or death:

•

Do not operate a broken or bent driveline. Such a driveline

will break apart while rotating at high speeds. Always

remove the implement from use until the damaged driveline

•

Always disconnect driveline from the tractor before

servicing the drivetrain and components powered by the

drivetrain. A person can become entangled in the drivetrain

if the tractor is started and the power take-off is engaged.

WARNING

!

To avoid serious injury or death:

A slip clutch that has been in use or has slipped for as little as

only two or three seconds during run-in may be too hot to

touch. Allow a hot clutch to cool before working on it.

The drivetrain and mower is protected from shock loads

with a friction slip clutch on the main driveline. Oxidation

caused by moisture and condensation on the clutch

friction surfaces can seize the inner frictions plates. To

remove oxidation, run the clutches through a “run-in”

cycle prior to initial operation, at the start of each season,

and when the clutch has not be used for approximately

60 days.

Clutch Run-in

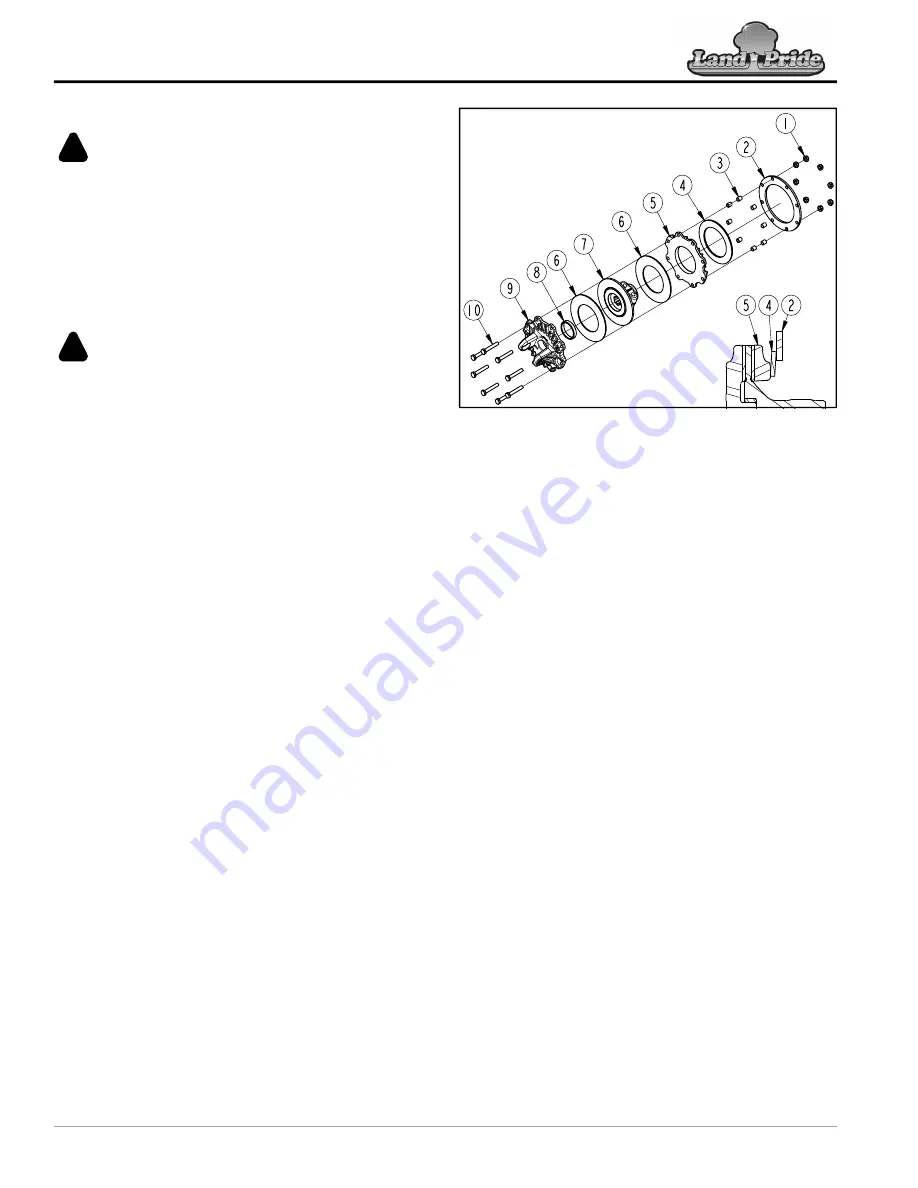

Refer to Figure 5-8:

1. With implement and driveline attached to the tractor,

shut tractor down according to

2. Disconnect driveline from the tractor.

3. Loosen all nuts (#1), draw nuts up snug, and then

tighten nuts one-half turn.

4. Reconnect driveline to the tractor. Refer to

5. Keep all bystanders away from the tractor and

implement.

6. From the tractor seat, start the tractor, and set the

engine speed at half throttle.

7.

Cycle the clutch on and off 5 or 6 times (15 seconds

on and 15 seconds off) or until the clutch visibly

smokes.

8. Shut tractor down according to

9. Disconnect the driveline from the tractor.

10. Tighten all nuts (#1) until spacers (#3) cannot be

rotated by hand and then back-off the nuts until the

spacers will rotate by hand.

11. Reconnect driveline to the tractor. Refer to

Slip Clutch Components

Figure 5-8

Inspect Friction Disc

Refer to Figure 5-8:

Do not touch the clutch while it is hot. Inspect friction

disc (#6) for wear and damage daily. Replace the disc

when they are worn down to nothing or damaged. Refer

to

Replace Friction Disc

Remove Driveline

1. Shut tractor according to

2. Pull back on the driveline lock collar and pull driveline

yoke from the tractor’s power take-off shaft.

3. Collapse the driveline by pushing the tractor end of

the driveline toward the opposite end of the driveline.

4. Remove bolt(s) clamping the slip clutch to the

implement.

5. The drive shaft with clutch is heavy. Grasp clutch

firmly with both hands and slide the clutch off the

implement.

Disassemble Clutch

Refer to Figure 5-8:

1. Place the clutch and universal joint assembly on a

bench with the clutch end accessible.

2. Remove nuts (#1) and bolts (#10). These bolts and

nuts hold the clutch together.

3. Remove compression plate (#2), spacers (#3), disc

spring (#4), pressure plate (#5), friction disc (#6), hub

flange (#7), friction disc (#6), and spacer (#8).

4. Discard friction disc (#6).

76560