20

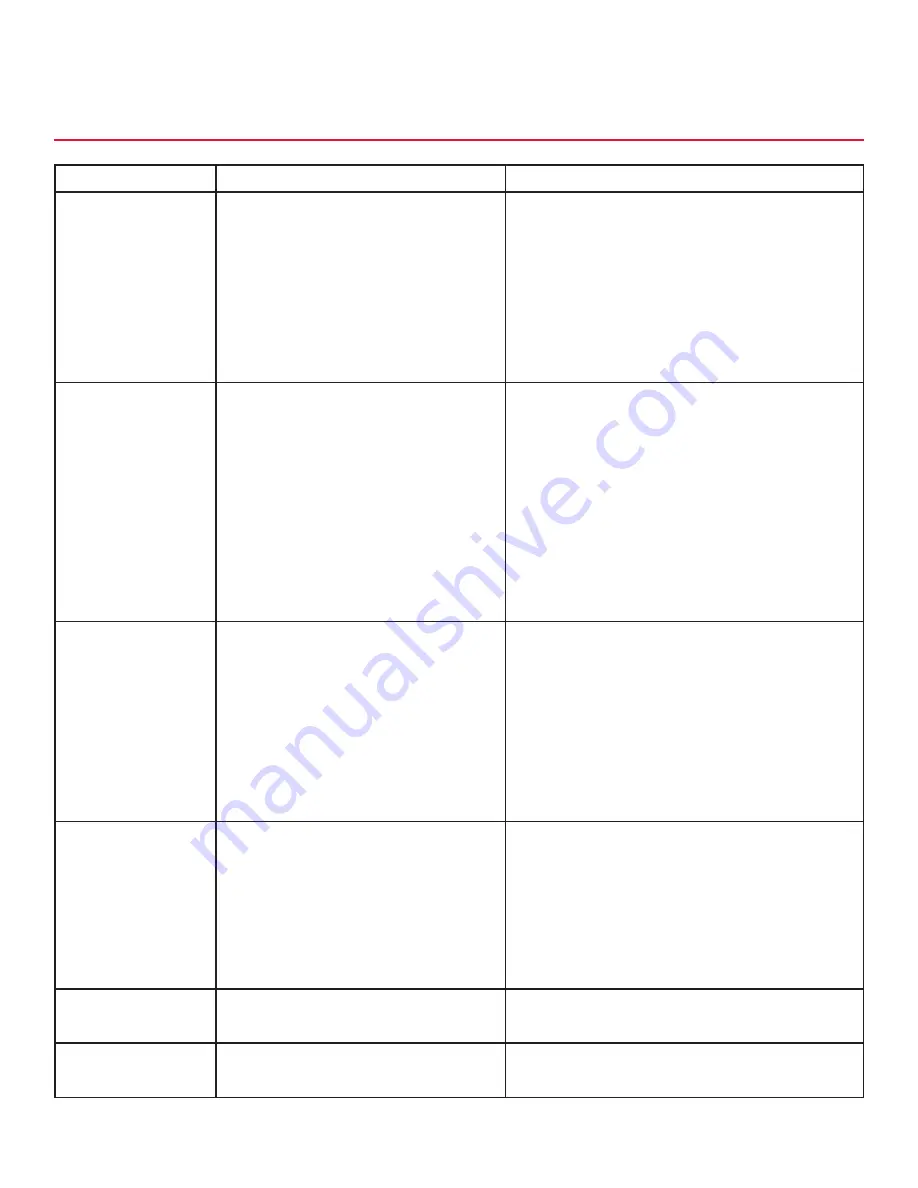

TROUBLE

CAUSE

REMEDY

No product when valve

is activated.

1. Keyswitch is off or keyswitch harness is

disconnected.

2. No power to dispenser.

3. Malfunctioning switch assembly.

4. Malfunctioning power supply.

5. Malfunctioning PCB board.

6. Malfunctioning LEV valve.

7. Malfunctioning bin switch.

1. Turn keyswitch on and/or reconnect keyswitch

harness.

2. Check internal breaker and incoming power.

3. Replace switch assembly.

4. Check voltage to power supply. Check fuses.

5. Replace PCB board.

6. Replace valve.

7. Replace bin switch.

Water only dispensed

(no syrup); or syrup only

dispensed (no water).

1. Syrup BIB empty.

2. Water or syrup shutoff on mounting block

not fully open.

3. Improper or inadequate water or syrup

supply.

4. CO

2

pressure to syrup pump too low.

5. Stalled or inoperative BIB pump.

6. Kinked line.

7. CO

2

regulator malfunction.

1. Replace syrup BIB as required.

2. Open shutoff completely.

3. Remove valve from mounting block & open shutoffs

slightly. Check water & syrup supply. If no supply,

check unit for other problems. Ensure BIB connec-

tion is engaged.

4. Check the CO

2

pressure to the pump to ensure it is

between 30 PSI - 80 PSI (0.207 MPA - 0.552 MPA).

5. Check CO

2

pressure and/or replace pump.

6. Remove kink or replace line.

7. Repair or replace CO

2

regulator as required.

Syrup only dispensed

(no water), but CO

2

gas

dispensed with syrup.

1. Improper water flow to dispenser.

2. Carbonator pump motor has timed out.

3. Liquid level probe not connected proper-

ly to PCB.

4. Defective PCB assembly.

5. Defective liquid level probe.

6. Weak or defective carbonator pump.

1. Check for water flow to dispenser.

2. Reset by turning the unit OFF, then ON by using the

circuit breaker on the power supply or momentarily

unplugging unit.

3. Check connections of liquid level probe to PCB

assembly.

4. Replace PCB assembly.

5. Replace liquid level probe.

6. Replace pump.

Excessive foaming.

1. No ice in bin.

2. Incoming water or syrup temperature too

high.

3. CO

2

pressure too high.

4. Water flow rate too high.

5. Nozzle and diffuser not clean.

6. Air in BIB lines.

1. Fill bin with ice and allow cold plate to restabilize.

2. Correct prior to dispenser.

3. Adjust CO

2

pressure, to 90 PSIG - 110 PSIG (0.621

MPA - 0.758 MPA).

4. Readjust and reset ratio.

5. Remove and clean.

6. Bleed air from BIB lines.

Off-taste in soda.

1. Leaking water check valve, allowing car-

bonated water to back into supply line.

1. Replace check valve.

Valves inoperable.

1. Loss of Power.

1. Check power supply to see if plugged in. Check

transformer circuit breaker. Check main power circuit

breaker, 110V.

Dispenser Troubleshooting

TROUBLESHOOTING