Taura 24 MCS W TOP

23

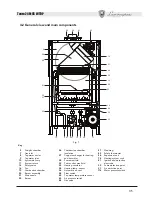

If the unit is enclosed in furniture or mounted alongside, there must be space for removing the casing and

for normal maintenance work.

2.3 Plumbing connections

The heating capacity of the unit should be previously established by calculating the building’s heat requirement ac-

cording to current regulations. The system must be equipped with all its components for it to work properly. It is

advisable to install on-off valves between the boiler and heating system allowing the boiler to be isolated from the

system if necessary.

The safety valve outlet must be connected to a funnel or collection pipe to prevent water flowing out onto

the ground in the event of over-pressure in the heating circuit. If this is not done, and the drain valve trips

and floods the room, the boiler manufacturer is not to be held responsible.

Do not use the water system pipes to earth electrical appliances.

Before installation, carefully wash all the pipes of the system to remove residues or impurities that could affect the

unit’s good working.

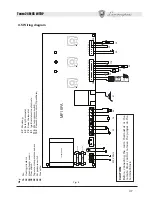

Make the connections to the corresponding connections as shown in fig. 6 in chap. IV and with the symbols on the

unit. A plumbing kit is available on request.

Characteristics of the water system

In the presence of water harder than 25° Fr, we recommend the use of suitably conditioned water in order to avoid

possible scaling in the boiler. Water treatment is indispensable in the case of very large systems or with frequent

introduction of replenishing water in the system. If partial or total emptying of the system becomes necessary under

these conditions, it is advisable to refill it with treated water.

Antifreeze system, antifreeze fluids, additives and inhibitors.

The boiler is equipped with an antifreeze system that turns on the boiler in heating mode when the system delivery

water temperature falls under 6°C. The device will not come on if the electricity and/or gas supply to the unit are cut

off. If it becomes necessary, it is permissible to use antifreeze fluid, additives and inhibitors only if the manufacturer

of these fluids or additives guarantees they are suitable for this use and cause no damage to the heat exchanger

or other components and/or materials of the boiler unit and system. It is prohibited to use generic antifreeze fluid,

additives or inhibitors that are not expressly suited for use in heating systems and compatible with the materials of

the boiler unit and system.

2.4 Gas connection

Before making the connection, ensure that the unit is arranged for operation with the type of fuel available

and carefully clean all the pipes of the gas system to remove any residues that could affect good functioning

of the boiler.

The gas must be connected to the relative connector (see fig. 7) in conformity with current standards, with rigid metal

pipes or with continuous flexible s/steel wall tubing, placing a gas cock between the system and the boiler. Make

sure that all the gas connections are tight.

The capacity of the gas meter must be sufficient for the simultaneous use of all equipment connected to it. The

diameter of the gas pipe leaving the boiler does not determine the diameter of the pipe between the unit and the

meter; it must be chosen according to its length and loss of head, in conformity with current standards.

Do not use the gas pipes to earth electrical appliances.