24

7

. Once the code/program has been downloaded, the

machine will start to operate.

Note

. Ensure that you are clear of the machine, as the

spindle will start to turn and could cause injury.

8

. The router will just cut the surface of the spoil board

the distance that you set in the design software, (we

suggest 1.6mm [1/16”]) and cut the outline of the job.

This will give you the location of the part on the spoil

board.

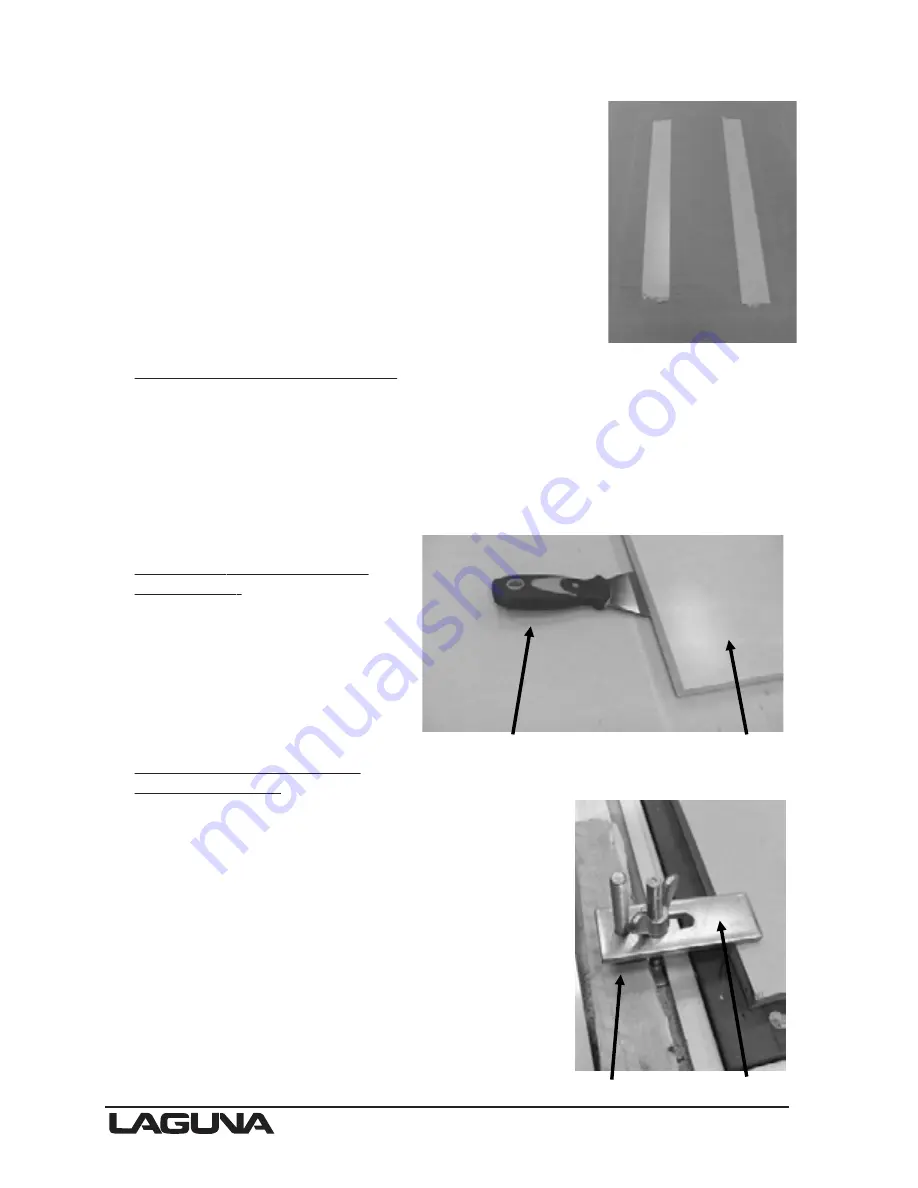

Fitting a Job to the Spoil Board

You can use double-sided tape to attach the job to the

spoil board. If you are using double-sided tape, ensure

that the spoil board and the job are clean and do not

have sawdust or chips, as this will affect the ability of

the tape to hold the job securely. Only use the smallest amount of double-sided

tape, as it will make it easer to remove the job once machined.

Removing the Job from the

Spoil Board

Lever the job off the spoil board

with a wide-blade putty knife or

similar.

Fitting the Job to the Table

Using the T-slots

You may find it convenient to

clamp the job to the spoil board

with the table clamps. This

attachment method can only be used if the outside

edges are not being machined.

When using the clamps, place a piece of packing

under the jacking bolt to protect the bed of the

machine.

Double- sided tape

inside job outline

Wide blade putty knife Job

Packing Clamp

Содержание MCNC Swift 48 X 96-0233

Страница 2: ......