1.

Loosen the three black plastic knobs.

2.

Fit the job between centers.

3.

Adjust the three bearings roughly equal around the circumference of the job

so that they are just touching the wood and clamp in position with the three

black plastic knobs.

4.

Rotate the job by hand to ensure that the adjustment of the steady is correct,

ensuring that all three bearings rotate

freely.

Fitting the tool rest

The machine is supplied with a tool rest

that is fitted to the copy saddle. To fit the

tool rest, the following parts, [if fitted to

the machine] must be removed:

- Guard.

- Saddle

tool

holder.

- Rotating

steady.

Clamp the tool rest holder to the saddle

with the 2 clamp screws and adjust to

suit the job. The vertical position of the

fence can be adjusted and then clamped

with the ratchet screw. An optional guide-

rail mounted tool rest holder is available

from Laguna tools.

Tailstock

The machine is supplied with a tailstock that can be adjusted along the guide rails of

the lathe. To clamp in the position, tighten the two bolts that are located at the back

with the wrench supplied. Rotating the handle located at the back of the tailstock can

extend or retract the tailstock spindle. The spindle has a female Morse taper MK2 for

fitting various centers and attachments. The spindle can be locked in position by

rotating the clamping screw that is located on the top of the tailstock at the front.

To fit the rotating center, rotate the spindle-adjusting handle so that the spindle is

approximately 50% extended. Clean the internal Morse taper of the tailstock and the

Morse taper of the center. Push the center into the spindle hole and it should lock in

position. To check that it is locked, try to rotate the fixed part of the center by hand.

To remove the center from the tailstock, rotate the spindle-adjusting handle so that

the spindle is retracted. The Morse taper of the center will come up against a dead

stop and if you continue to retract the spindle the center will be freed. Keep your

hand under the center so that it is not allowed to fall and become damaged.

The machine is supplied with two types of rotating centers; one for general-purpose

work and the second one for use when using the rotating steady on the copy saddle.

The lathe is supplied with drill chuck [1/16” to 5/8” drill capacity] that also fits into

the tailstock.

When hand-turning spindles

[non-copy turning],

etc., you may find it more

convenient to remove the tailstock and refit on the other side of the copy saddle.

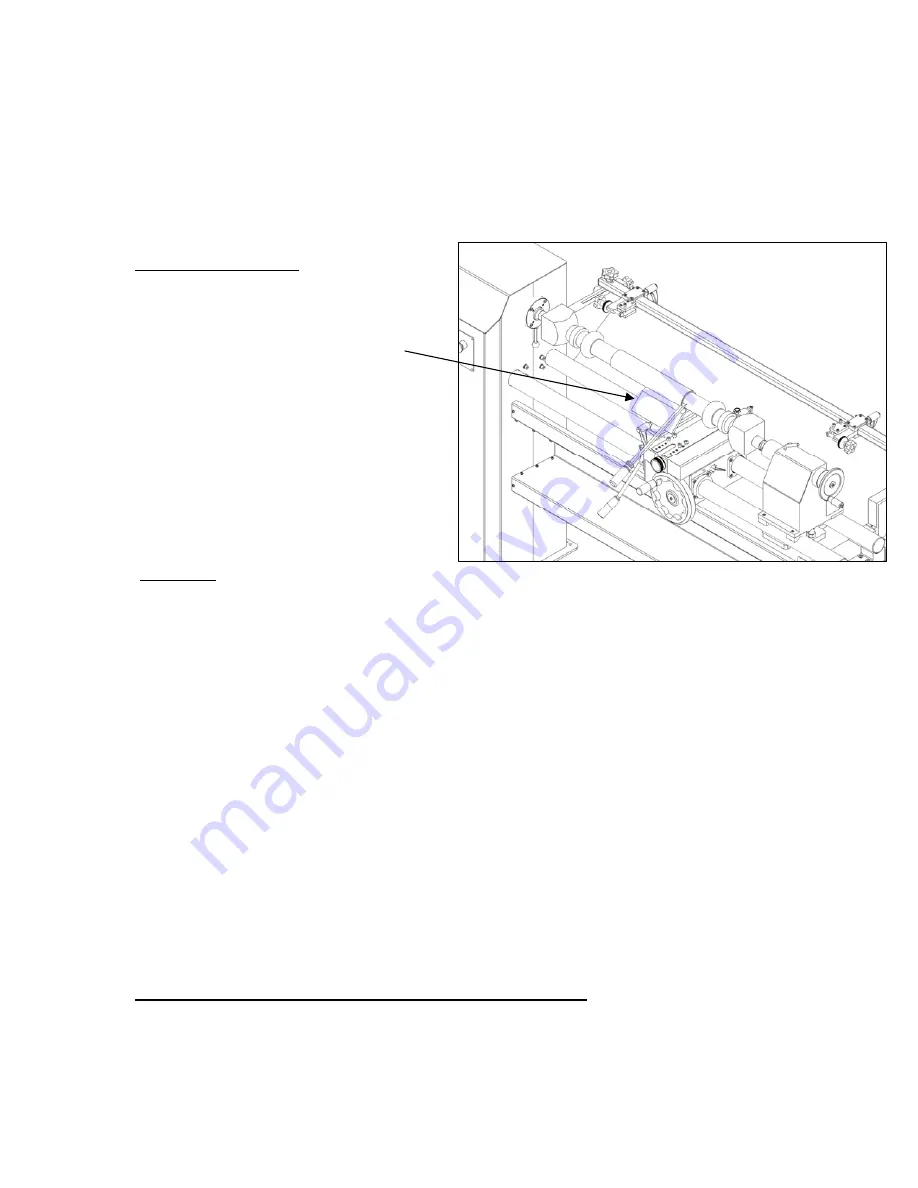

To assemble the rotating steady onto the copy saddle

Note: The rotating center is located on the saddle by two spring pins [dowels]. Care

must be taken to ensure that they line up with the relevant holes while assembling.

14

Содержание CL1200

Страница 23: ...23...

Страница 26: ...CL 01 00 00 00 LONGITUDINAL SUPPORT 28...