Pennant Pool Heater

Page 15

normally-open contact(s) of the airflow pressure

switch(es). This allows the ignition module to proceed

with the ignition sequence.

The blocked flue pressure switch senses the

pressure difference between the exhaust plenum and

the blower inlet plenum. It will interrupt the airflow

sensing circuit if this pressure exceeds a maximum

value. If airflow is not proven, the ignition module

will either attempt ignition again (up to three times) or

will lockout (if the optional lockout ignition module is

used).

The ignition module checks that the ignitor

current has reached a minimum value and energizes

the gas valves at the end of the ignitor-heating period.

The green indicators on the front panel will light,

indicating that the gas valves are open.

After a 4-second trial for ignition, the ignitor

switches off, and unless the flame sensor detects a

flame, the gas valves will close and the ignition

module will either attempt ignition again (up to three

times) or will lockout (if the optional lockout ignition

module is used).

Note: at this point, if gas pressure is

below the required 5" w.c. minimum, the pool heater

will lock out.

If flame is sensed, the burner will continue to fire

as long as there is a call for heat. Pennant 1250, 1500,

1750 and 2000 models start at part load. When the gas

valves controlled by the first ignition module are

energized, the second ignition module is energized and

enters the same ignition sequence just described. If

there is a subsequent loss of flame signal, the burner

will attempt re-ignition up to three times (only once if

optional lockout ignition module is used.) Loss of

flame signal from the first ignition module will cause

shutdown of the heater.

When the call for heat is satisfied, the gas valves

close and the blower(s) continues to run for 30

seconds. The pump will continue to run for the length

of time selected at startup by the adjustment of the

pump time delay (Pd).

If a call for heat is prevented from being satisfied

either by a safety interlock or due to an ignition

lockout, the red “Service” indicator on the front panel

will light. To reset the standard ignition module,

toggle the Pennant power switch off, and then on

again. (To reset the optional single try lockout ignition

module, the reset button on the module must be

pressed. Interrupting power to this module will not

reset the lockout.)

The Pennant 1250, 1500, 1750 and 2000 models

have two ignition modules that control different

burners.

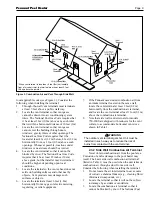

6.2 Filling the Heater System

1.

Ensure the system is fully connected, filled with

water and all valves are open.

2.

Start up heater according to the procedure in this

manual. Operate the entire system for one (1) hour.

3.

After placing the unit in operation, the ignition

system safety shutoff device must be tested.

First, shut off the manual gas valve, and call the

unit for heat. After the pre-purge and ignitor

heat-up time, the main gas terminals will be

energized, attempting to light, for four (4)

seconds, and then will de-energize. The unit will

go into lockout mode. Second, turn the power off

and then on again, push the reset button (optional

Ignition Module only), open the manual gas

valve and allow the unit to light. While the unit

is operating, close the manual gas valve and

ensure that power to the main gas valve no

longer exists.

4.

Check the entire system for leaks.

Caution

Protect the heater from low pH water if an “acid

start up” or similar technique is used. Corrosion of

the heater and heat exchanger due to low pH water

is not covered under the limited warranty. The water

must be neutralized to normal pH levels before

filling the heater and starting up the system.

Important:

The installer is responsible for identifying

to the owner/operator the location of all emergency

shutoff devices.

WARNING

Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

that may have been under water.

6.3 Operating the Burner and Set Up

6.3.1 Set Up for 0 to 2500 Feet Altitude

The setup must be checked before the unit is put

in operation. Problems such as failure to start, rough

ignition, strong exhaust odors, etc. can be due to

improper setup. Damage to the heater resulting from

improper setup is not covered by the limited warranty.

1.

Using this manual, make sure the installation is

complete and fully in compliance with the

instructions.

2.

Determine that the appliance and system are

filled with water and all air has been bled from

both. Open all valves.

3.

Observe all warnings on the Operating

Instructions label and turn on gas and electrical

power to appliance.

4.

Switch on the appliance power switch located on

the right side of the unit.

5.

The Pennant will enter the start sequence, as long

as the unit is being called for heat. The blower

and pump come on for pre-purge, then the ignitor

warm-up sequence starts and after the ignitor

Содержание Pennant PNCP 1000

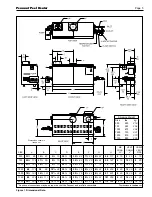

Страница 28: ...LAARS Heating Systems Page 28 Figure 9 Sheet Metal Components...

Страница 29: ...Pennant Pool Heater Page 29 Figure 10 Internal Components...

Страница 30: ...LAARS Heating Systems Page 30 Figure 11 Heat Exchanger Components A See pump chart below for pump numbers...

Страница 31: ...Pennant Pool Heater Page 31 Figure 12 Pennant 500 1000 Ladder Diagram SECTION 10 Wiring Diagrams...

Страница 32: ...LAARS Heating Systems Page 32 Figure 13 Pennant 1250 2000 Ladder Diagram...

Страница 33: ...Pennant Pool Heater Page 33 Figure 14 Pennant 500 1000 Wiring Schematic...

Страница 34: ...LAARS Heating Systems Page 34 Figure 15 Pennant 1250 2000 Wiring Schematic...

Страница 35: ...Pennant Pool Heater Page 35 Figure 16 Field Wiring PNCP 500 1000...