LAARS Heating Systems

Page 12

of hot water from the heater when the filter pump

stops running.

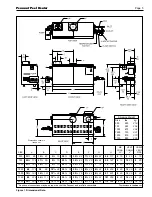

See Figure 6 for proper connection of the

Pennant heater to the pool loop.

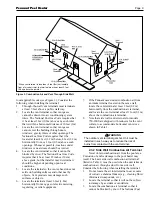

4.2 Automatic Chlorinators

A concentration of chlorine in the heater can be

very destructive; therefore the following rules about

the installation and operation of such devices must be

followed:

1.

The chlorinator should be installed so it introduces

the gas or solution downstream of the heater.

2.

The chlorinator should be wired so it cannot

operate unless the filter pump is operating.

3.

The chlorinator should be provided with an anti-

siphon device so that the draining of the piping

after the pump shuts off will not siphon chlorine

solution into the heater.

4.

When the operation of a chlorinator is such that

it must be installed in the pump suction, or some

other place where the chlorine solution flows

through the heater, corrosion of the heater can

occur. Excessive concentrations of chlorine

resulting from improper adjustment or

chlorinator equipment failure are responsible for

this corrosion. The heater warranty does not

cover the resulting damage to the heat exchanger.

4.3 Sensor Locations

Two sensors must be installed in the pool loop,

as shown in Figure 5. The inlet sensor for the

temperature control must be installed in the pool loop

Figure 6. Pool Heater Piping.

The Pennant Pool Heater is shipped with a field-installed mixing system, and must be piped in primary-

secondary style, as shown. A remote pool temperature sensor and remote pool temperature high limit

are wired to the Pennant, to be mounted in the pool water loop, as shown.

within 12” (30 cm) of the inlet to the heater. This

sensor is

not

installed in a well. For sensitivity, it must

be installed in direct contact with the pool water flow.

The second sensor, the high limit sensor, must be

installed in the pool loop within 12” (30 cm)

downstream of the heater outlet. This sensor is a

capillary and bulb. It shall be used with the immersion

well that is provided.

SECTION 5.

Electrical Connections

WARNING

The appliance must be electrically grounded in

accordance with the requirements of the authority

having jurisdiction or, in the absence of such

requirements, with the latest edition of the National

Electrical Code, ANSI/NFPA 70, in the U.S. and

with latest edition of CSA C22.1 Canadian Electrical

Code, Part 1, in Canada. Do not rely on the gas or

water piping to ground the metal parts of the boiler.

Plastic pipe or dielectric unions may isolate the

boiler electrically. Service and maintenance

personnel, who work on or around the boiler, may

be standing on wet floors and could be electrocuted

by an ungrounded boiler.

Single pole switches, including those of safety

controls and protective devices must not be wired in a

grounded line.

All electrical connections are made in the field

Содержание Pennant PNCP 1000

Страница 28: ...LAARS Heating Systems Page 28 Figure 9 Sheet Metal Components...

Страница 29: ...Pennant Pool Heater Page 29 Figure 10 Internal Components...

Страница 30: ...LAARS Heating Systems Page 30 Figure 11 Heat Exchanger Components A See pump chart below for pump numbers...

Страница 31: ...Pennant Pool Heater Page 31 Figure 12 Pennant 500 1000 Ladder Diagram SECTION 10 Wiring Diagrams...

Страница 32: ...LAARS Heating Systems Page 32 Figure 13 Pennant 1250 2000 Ladder Diagram...

Страница 33: ...Pennant Pool Heater Page 33 Figure 14 Pennant 500 1000 Wiring Schematic...

Страница 34: ...LAARS Heating Systems Page 34 Figure 15 Pennant 1250 2000 Wiring Schematic...

Страница 35: ...Pennant Pool Heater Page 35 Figure 16 Field Wiring PNCP 500 1000...