2H9

2-3-9

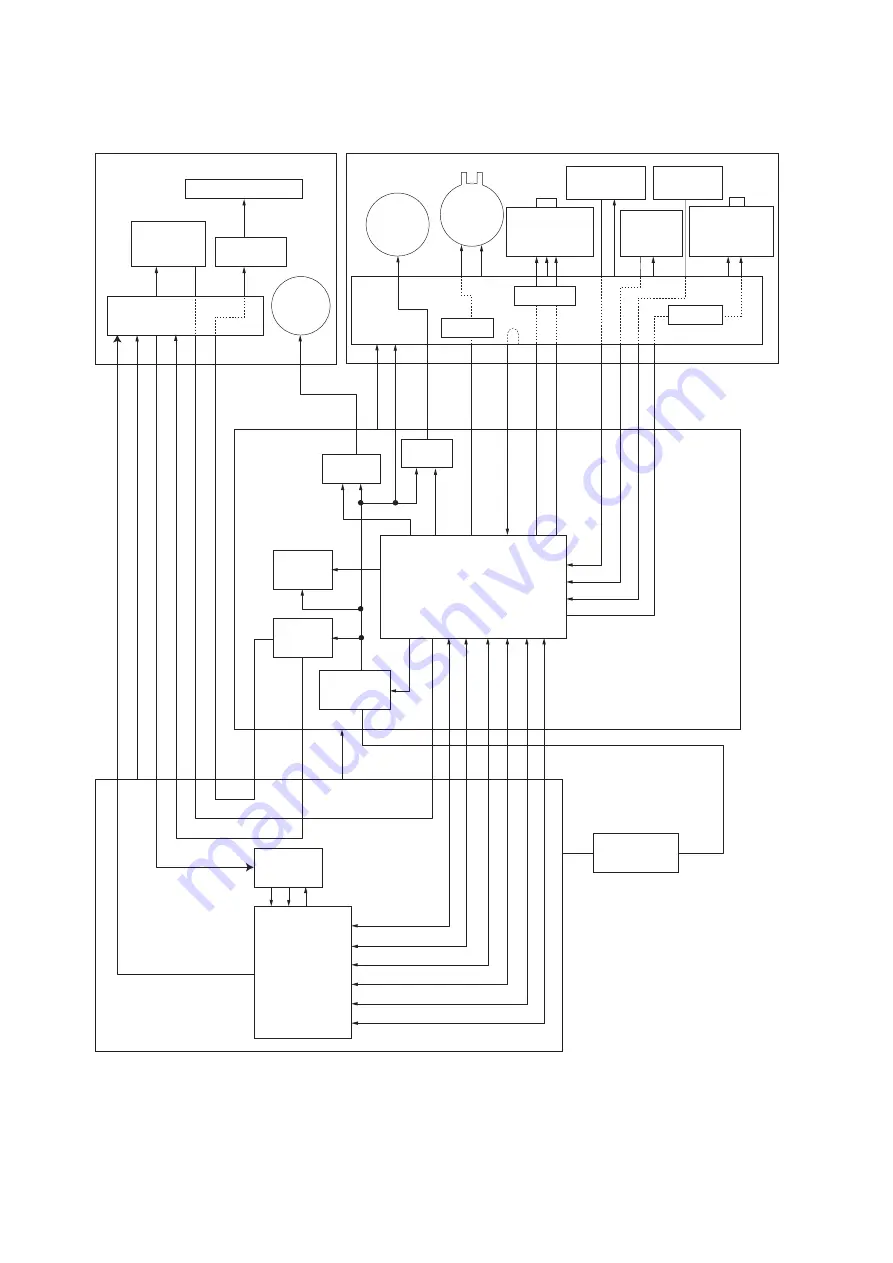

2-3-3 Scanner PWB

Figure 2-3-5Scanner PWB block diagram

Image scanner

unit (ISU)

Scanner PWB

Regulator

LAMP

CPU

Control PWB

ASIC

AFE

Power save

circuit

Power source

PWB

Optional document

processor (DP)

Exposure lamp

ISU

motor

CCD PWB

Home

position

sensor

Inverter

PWB

Driver

Driver

Driver

Motor

driver

Motor

driver

FEEDCLN

DPDETN

PRESOLN

RELSOLN

P

AGESET

OPSWN

ORGSWN

REVSOLN

+3.3V1

+24V4

LAMP

HPSWN

+12V

CSI

+5V1

+3.3V1

+24V1

DP driver PWB

DP timing

sensor

DP original

sensor

DP

open/close

sensor

DP

paper

feed

motor

DP

paper

feed

clutch

DP switchback

feedshift

solenoid

DP switchback

pressure

solenoid

Содержание KM-2810

Страница 1: ...SERVICE MANUAL Published in May 2009 2H9SM060 First Edition KM 2810 ...

Страница 3: ...Revision history Revision Date Replaced pages Remarks ...

Страница 4: ...This page is intentionally left blank ...

Страница 10: ...This page is intentionally left blank ...

Страница 18: ...2H9 1 1 6 This page is intentionally left blank ...

Страница 22: ...2H9 1 2 4 5 Remove nine tapes Figure 1 2 5 Tape Tapes Tapes Tapes Tapes ...

Страница 24: ...2H9 1 2 6 This page is intentionally left blank ...

Страница 105: ...2H9 1 5 15 7 Unhook four hooks and then remove the scanner unit Figure 1 5 19 Scanner unit Hooks Hooks ...

Страница 138: ...2H9 1 5 48 This page is intentionally left blank ...

Страница 157: ...2H9 2 1 17 Figure 2 1 24 Paper exit section block diagram EXITN YC19 3 Fuser unit Exit sensor Control PWB ...

Страница 162: ...2H9 2 2 4 This page is intentionally left blank ...

Страница 174: ...2H9 2 3 12 This page is intentionally left blank ...

Страница 178: ...2H9 2 4 4 This page is intentionally left blank ...

Страница 179: ......

Страница 180: ......