PERIODIC SERVICE

46

ENGLISH

A

Fuel blend differs from season to season for the best

seasonal engine performance. To prevent engine

performance troubles such as vapor lock or hard

starting, use fuel within the season in which the fuel is

purchased.

A

Infrequent use of the engine during a season can

make fuel stale in the fuel tank of the machine. Stale

fuel condition can cause engine performance troubles

by varnish and plugged carburetor components.

A

Seal the fuel storage container tightly and store it out

of sunlight and heat to prevent fuel degradation.

A

Condensation in the fuel tank may occur because of

various operating or environmental conditions. To

reduce condensation and avoid affecting machine

operation, fill the fuel tank at the end of daily

operations.

A

Do not use old fuel.

[Use of alcohol mixed gasoline (Gasohol)]

Use "gasohol" only when the ethanol additive is less than

10% of the fuel. The use of methanol additive is not

recommended. For the best results, use unleaded fuel

with a minimum of 87 octane.

B

Checking and Cleaning Radiator Screen

and Bonnet Screen to Prevent

Overheating

To avoid serious injury or death:

A

Engine components can get extremely hot from

operation. To prevent severe burns, do not

touch these areas while the engine is running,

or immediately after it is turned off.

Never operate the engine without heat shields

or guards.

To avoid personal injury:

A

Be sure to stop the engine and remove the key

before cleaning.

A

The air intake area must be clear of debris to prevent

the engine from overheating.

Daily or after every 5 hours of operation, check to be sure

the radiator screen and the bonnet screen are clean.

Dirt or chaff on the radiator screen, bonnet screen or

radiator decrease cooling performance.

1. Remove the radiator screen and the bonnet screen,

and remove all foreign material.

2. Remove the dust from between the fins and the tube.

3. Tighten the fan drive belt as necessary. For this, refer

to "EVERY 100 HOURS" in "PERIODIC SERVICE"

section.

4. If the scale forms in the tube, clean with the scale

inhibitor or its equivalent.

5. Each time the bonnet screen is covered with grass

during operation, rub it off the screen with the hand.

Check the radiator screen from time to time if grass

accumulates.

6. If the dust or chaff has accumulated inside of the

bonnet, remove the radiator screen and clean inside

completely.

After cleaning, replace the radiator screens properly.

7. Check the radiator for dust or chaff build up.

If the dust or chaff has accumulated in the radiator,

clear with air pressure (not to exceed 205 kPa (2.1 kgf/

cm , 30 psi)) or a hose.

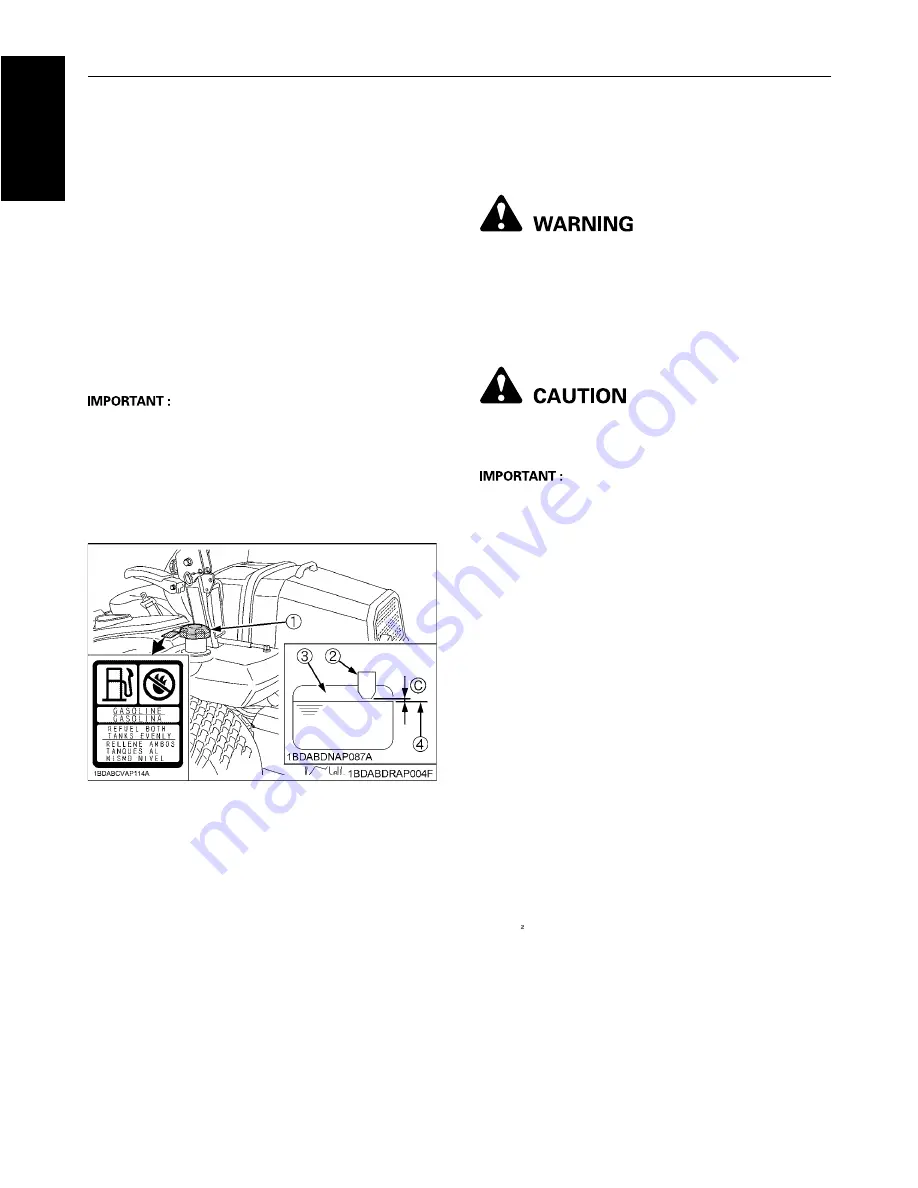

(1) Fuel tank cap

(2) Fuel tank filler neck

(3) Empty space

(4) Max. fuel level

(C) Clearance

(Fuel level is under the filler neck.)

Содержание ZG332

Страница 1: ...OPERATOR S MANUAL READ AND SAVE THIS MANUAL MODEL ZG332 1BDABDRAP0010 ENGLISH ...

Страница 13: ...SAFE OPERATION 6 ENGLISH 7 DANGER WARNING AND CAUTION LABELS ...

Страница 14: ...7 SAFE OPERATION ENGLISH ...

Страница 15: ...SAFE OPERATION 8 ENGLISH ...

Страница 17: ......

Страница 19: ...SERVICING OF MACHINE 2 ENGLISH 1 ROPS serial No ...

Страница 55: ...MAINTENANCE 38 ENGLISH PERIODIC SERVICE CHART LABEL 1 Part No K3241 6552 ENGLISH 2 Part No K3241 6553 SPANISH ...